Single-photon avalanche diode, manufacturing method thereof, detector array and image sensor

A single-photon avalanche and diode technology, applied in diodes, electro-solid devices, semiconductor devices, etc., can solve the problems of reduced absorption efficiency of incident photons, reduced absorption efficiency, and difficult processing of excessively thick device layers, so as to improve light absorption efficiency. , Improve the absorption efficiency and overcome the effect of low light absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

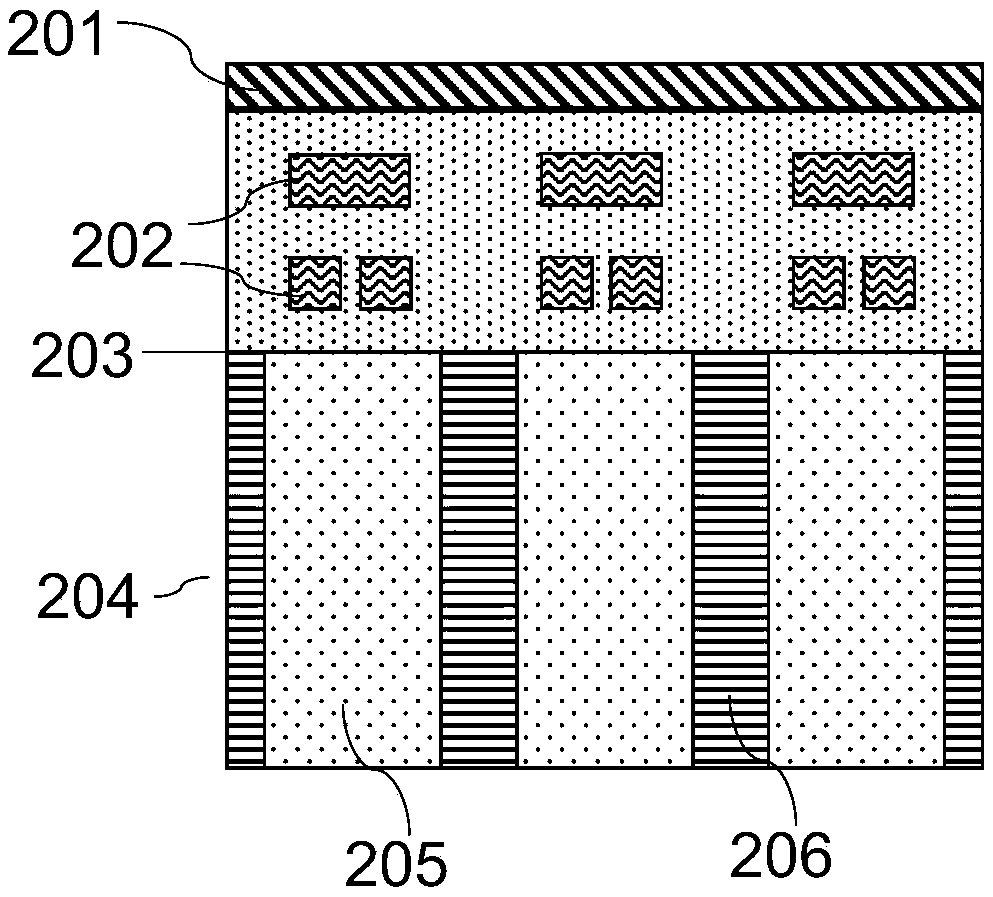

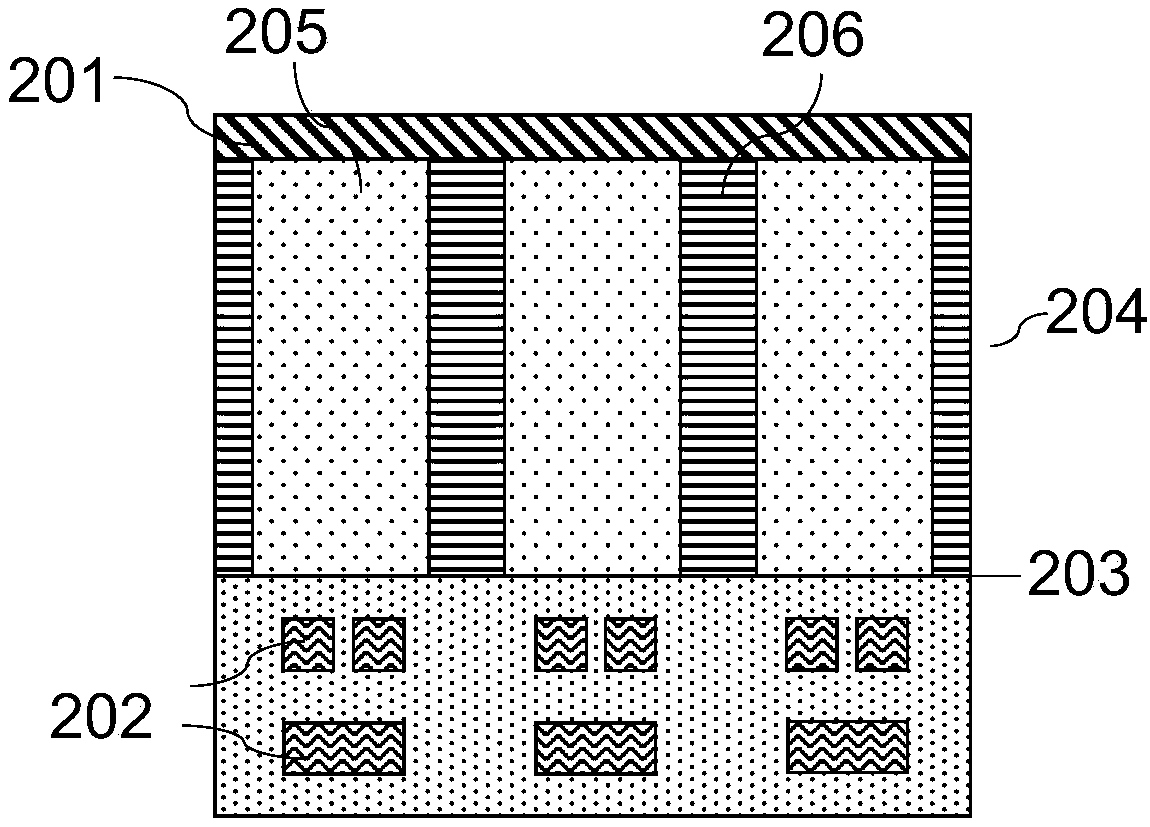

[0068] A back-illuminated single-photon avalanche diode. The back-illuminated single-photon avalanche diode is sequentially provided with a substrate, a circuit layer, a silicon oxide layer, and a silicon detection layer from bottom to top. The silicon detection layer includes a first-type doped region, a second Type doped region, third type doped region and side wall reflection wall, the second type doped region or the third type doped region forms a multiplication junction with the first type doped region, the third type doped region is In the doping region where the doping concentration changes, a light trapping structure is arranged in the back-illuminated single photon avalanche diode. Further, an anti-reflection structure is also provided on the upper surface of the back-illuminated single photon avalanche diode.

[0069] Since the back-illuminated single-photon avalanche diode is equipped with a light-trapping structure and a side wall reflective wall, the incident ligh...

Embodiment 2

[0071] Embodiment 2 is obtained based on the further improvement of Embodiment 1. The light trapping structure is arranged on the upper surface of the back-illuminated single photon avalanche diode and / or above and / or below the silicon oxide layer, and the light trapping structure on the upper surface The light-trapping structure above the silicon oxide layer or the light-trapping structure below the silicon oxide layer can be set alone to improve the light absorption efficiency of the back-illuminated SPAD, and can also be used in combination. Further, the light-trapping structure is a nanoscale or micron-scale concave-convex structure, for example, the light-trapping structure can be an inverted pyramid structure 1 (refer to Figure 10 ) or shallow trench structure 20 (such as Figure 12 As shown, the shallow trench structure 20 is arranged on the upper surface of the SPAD), or the surface is a structure such as a honeycomb surface, a sinusoidal grating textured surface, a d...

Embodiment 3

[0075] Obtain embodiment 3 based on the further improvement of embodiment 1, refer to Figure 10 , Figure 10 It is a schematic cross-sectional structure diagram of the third embodiment of a back-illuminated single-photon avalanche diode in the present invention; the light-trapping structure and / or the anti-reflection structure is an inverted pyramid structure 1, and the inverted pyramid structure 1 has both light-trapping and anti-reflection functions Specifically, the inverted pyramid structure 1 is disposed on the upper surface of the back-illuminated SPAD (that is, disposed above the third-type doped region 8), and the inverted pyramid structure 1 is obtained by filling silicon oxide after etching on the silicon base. In this embodiment, an insulating dielectric protection layer 13 is provided above the inverted pyramid structure 1 for protecting the SPAD. Specifically, the inverted pyramid structure 1 placed on the upper surface of the SPAD can form a gentle and gradual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com