Composite collagen dressing for burnt injury wound surface restoration and preparation method thereof

A technology of wound repair and collagen, applied in medical science, bandages, absorbent pads, etc., can solve the problems of limited repair effect and no obvious advantages in removing scars, and achieve the effect of speeding up repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

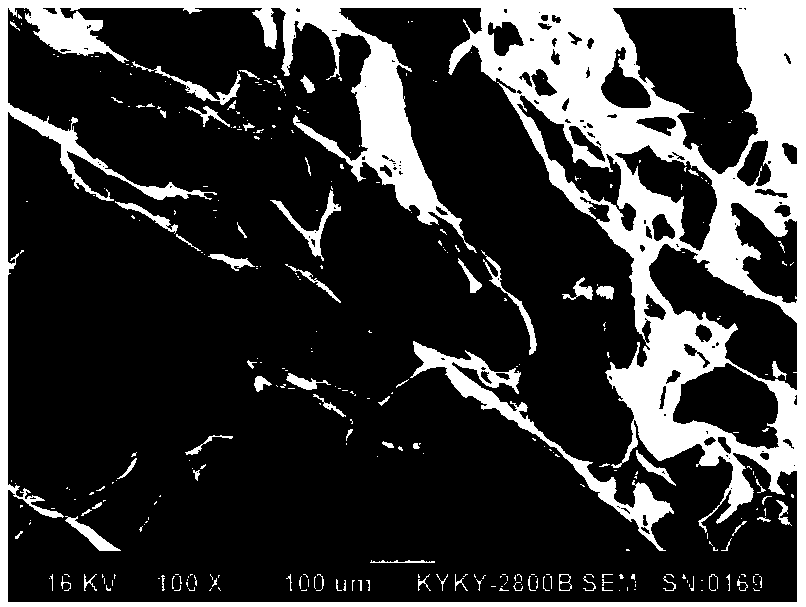

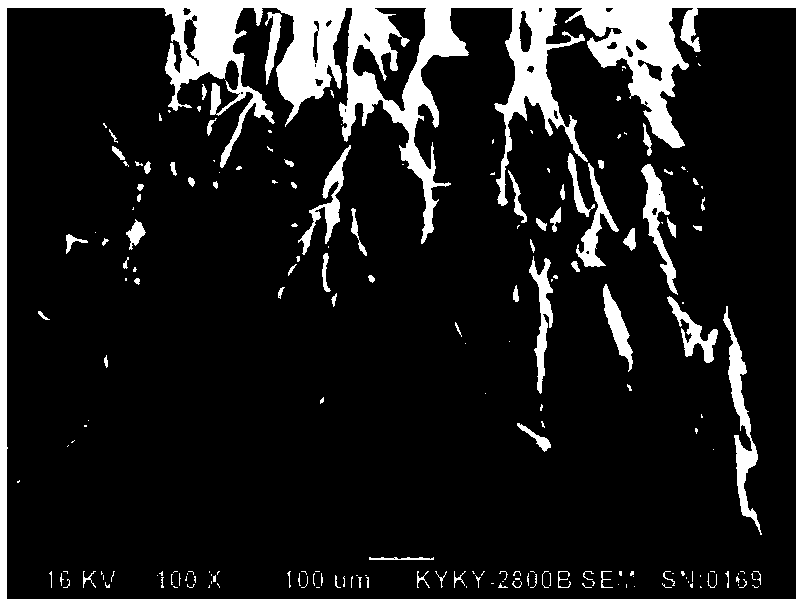

Image

Examples

experiment example 6

[0052] Rat materials in Experimental Example 6 were purchased from the Experimental Animal Center of Tianjin Medical University.

[0053] The 1st group of embodiment, the present invention is used for the composite collagen dressing of wound surface of human body

[0054] The embodiment of this group provides a composite collagen dressing for human body wound repair. All the examples in this group have the following common features: they are formed by mixing and compounding two or more different types of collagen.

[0055] In some embodiments, the different types of collagen are selected from the group consisting of collagen type I, collagen type III, collagen type V;

[0056] The type I collagen is derived from pigskin, cowhide, bovine Achilles tendon;

[0057] The type III collagen is derived from human or animal blood vessel walls, uterine walls, and amniotic membranes;

[0058] The type V collagen is derived from human or animal amniotic membrane, serous membrane and pl...

experiment example 1

[0093] Experimental Example 1: Preparation of Spongy Formulation

[0094] (1) Weigh collagen types I, III, and V, disperse them in distilled water according to the ratio of 95.4:3.82:0.78 (W / W / W), and mix and homogenize with a high-speed mixer;

[0095] (2) Place the homogenate in a certain container, then pre-freeze it in a -80°C ultra-low temperature refrigerator for 24 hours, and then dry it in a -50°C freezer vacuum dryer for 24 hours;

[0096] (3) Take out the loose and porous spongy collagen material after freeze-drying, and cut it into different shapes and sizes according to application requirements.

experiment example 2

[0097] Experimental Example 2: Preparation of Micropowder

[0098] (1) Weigh collagen types I, III, and V, disperse them in distilled water according to the ratio of 93.65:6.32:1.03 (W / W / W), and mix and homogenize with a high-speed mixer;

[0099] (2) Place the homogenate in a certain container, place it in a vacuum drying oven for vacuum defoaming for 2 hours, and then dry it in a freezer vacuum dryer at -50°C for 24 hours;

[0100] (3) Pulverizing the freeze-dried composite collagen material into small pieces, placing it in a liquid nitrogen grinder, setting a grinding program according to the particle size of the required micropowder, and performing liquid nitrogen grinding;

[0101] (4) The composite collagen micropowder after liquid nitrogen grinding treatment is placed in a vacuum dryer for several hours at low temperature and vacuum drying to obtain a composite collagen micropowder material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com