Growth device for sodium flux method gallium nitride single crystal

A technology of sodium flux method and growth device, which is applied in the field of growth device of gallium nitride single crystal by sodium flux method, which can solve the problems of changing crystal growth characteristics, crystal coloring, high concentration of nitrogen atoms, and difficulty in obtaining epitaxial layers, etc., to achieve Effect of pure growth conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

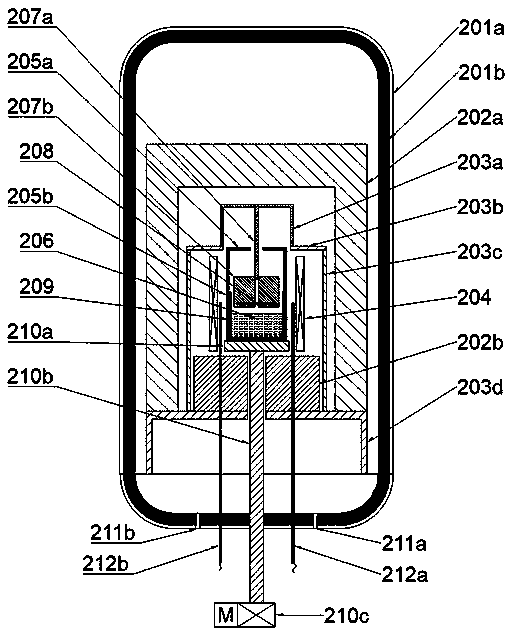

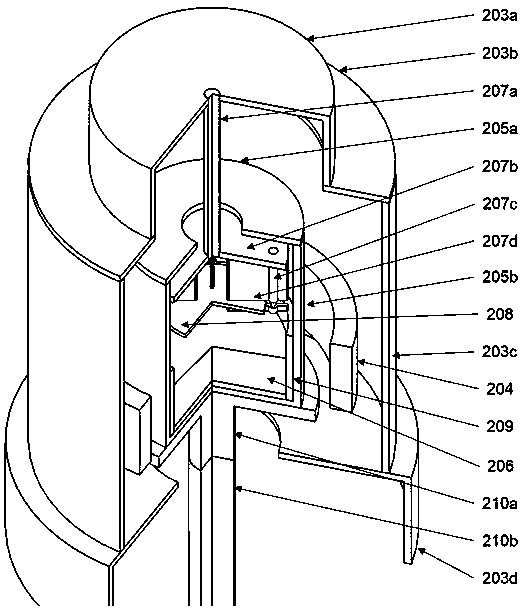

[0017] Such as figure 2 , image 3 As shown, a device for growing gallium nitride single crystal by sodium flux method includes a water-cooled cavity 201a, an air inlet 211a, an exhaust hole 211b and a pressure vessel cavity 201b, and the main structure is the same as that of a conventional device. The interior of the main structure includes a crucible 209 for loading the seed crystal 208 and the molten metal 206, a support structure, and an insulation layer; meanwhile, the interior of the main structure also includes a heater 204, a temperature control thermocouple 212a, and a temperature measurement thermocouple 212b; The growth device also includes a seed crystal fixture composed of a seed crystal fixture fixing rod 207a, a seed crystal fixture fixing plate 207b and a seed crystal fixture clamping rod 207c inside the main body; it also includes a reaction vessel cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com