Method for recovering anode material of waste lithium ion battery

A technology for lithium ion batteries and cathode materials, which is applied in the field of cathode material recovery of waste lithium ion batteries, can solve the problems of high recovery value, high recovery cost, large consumption of reagents, etc., achieves recovery and regeneration of valuable resources, and is conducive to popularization and popularization. , to achieve the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

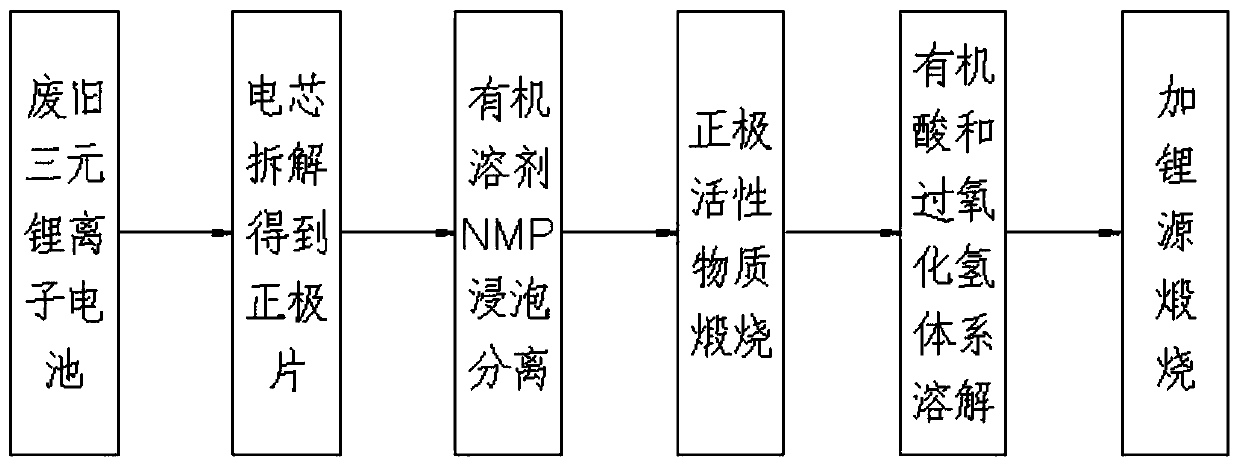

[0058] The recovery of waste lithium iron acid, lithium vanadium phosphate, and lithium-rich manganese-based positive electrode materials includes the following steps:

[0059] Carry out performance evaluation on the waste lithium-ion battery, after the evaluation is completed, perform discharge treatment and disassemble the battery cell to obtain the positive plate;

[0060] Put the positive electrode sheet into a liquid nitrogen freezer for crushing, soak it in organic solvent NMP, stir and ultrasonically treat it, and separate the positive electrode active material from the current collector after screening and washing;

[0061] After drying the positive electrode active material, it is calcined at a high temperature in a muffle furnace, and the sample is ground after calcining;

[0062] Mix and stir the organic acid and water to react and filter; enrich the filtrate to obtain a high-concentration lithium-containing solution and then recover the lithium in the positive elec...

Embodiment 2

[0064] Adopt the method of the present invention to reclaim the cathode material of waste lithium ion battery, comprise the following steps:

[0065] Disassemble the cell to get the positive plate

[0066] Carry out performance evaluation on the waste ternary lithium-ion battery, after the evaluation is completed, perform discharge treatment and disassemble the battery cell to obtain the positive plate;

[0067] The performance of the lithium-ion battery is evaluated by using the old lithium-ion power battery with no damage to the outer shell and keeping the shape of the entire single battery intact;

[0068] The remaining capacity of the selected power battery is lower than 80% of the standard battery capacity, and the internal resistance is larger than that of the new battery, showing extremely poor inconsistency, unable to meet the high performance requirements, and can no longer be used in waste power batteries in electric vehicles;

[0069] The battery cell is disassembl...

Embodiment 3

[0087] Determination of Optimum Parameters for Immersion Separation of Organic Solvent NMP

[0088] Put the positive electrode sheet into liquid nitrogen to freeze and cut it into a square with a side length of 0.5-1cm, and soak it in NMP, an organic solvent with different liquid-material ratios, for different times;

[0089] It is stirred and ultrasonically treated, and the time of ultrasonic treatment is set at different times for testing; after screening and washing, the positive electrode active material is separated from the current collector;

[0090] After experimenting with ultrasound at 50-60°C for 1 hour, the positive active material was separated from the current collector after sieving and washing;

[0091] The liquid-to-material ratio of the organic solvent NMP and the positive electrode sheet is 8-10:0.8-1;

[0092] The positive active material is separated from the current collector after being sieved and washed by ultrasonication for 1 hour at 60°C;

[0093] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com