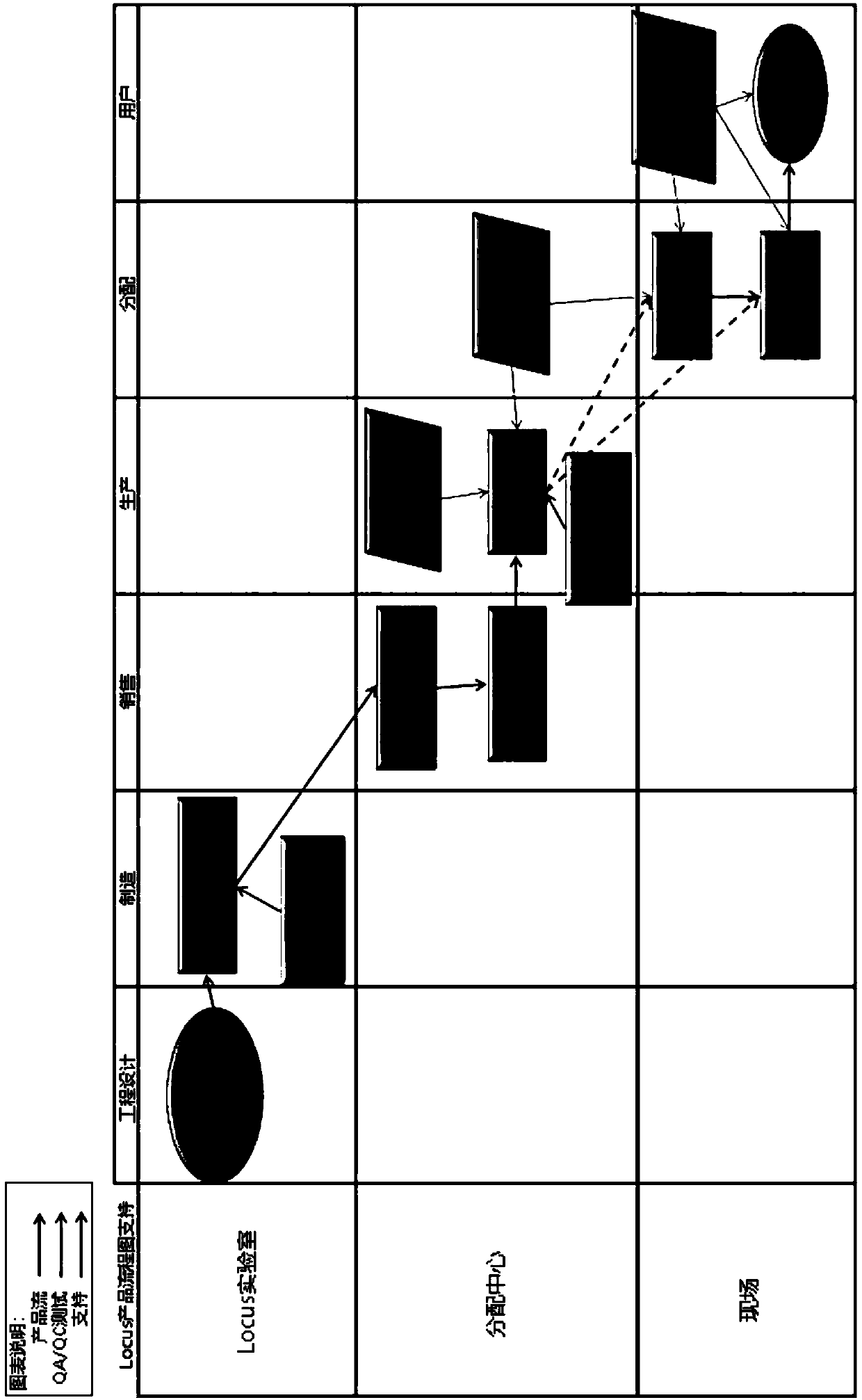

Distributed systems for the efficient production and use of microbe-based compositions

A microbial source and microbial technology, applied in the direction of bioreactor/fermenter combination, drug combination, biomass pretreatment, etc., can solve problems such as damage, achieve the effect of reducing production scale, increasing production, reducing inventory and distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0094] Preparation of products of microbial origin

[0095] A product of microbial origin according to the invention is simply a fermented nutrient solution containing the microorganisms and / or microbial metabolites produced by the microorganisms and / or any residual nutrients. The fermented product can be used directly without extraction or purification. Extraction and purification, if desired, are readily accomplished using standard extraction methods or techniques described in the literature.

[0096] Microorganisms in products of microbial origin may be in viable or inactive form. Products of microbial origin can be used without further stabilization, preservation and storage. Advantageously, the direct utilization of these microbially derived products maintains high microbial viability, reduces the possibility of contamination from foreign agents and undesired microorganisms, and maintains the viability of by-products of microbial growth.

[0097] Microorganisms and / or ...

Embodiment 1

[0210] Example 1 : Fermentation of Candida globosa for sophorolipid (SLP) production in a 110 L dispensable reactor.

[0211] A portable, airlift, fully enclosed reactor operated by PLC with water filtration, temperature control unit and ventilator on panel was used. The reactor had a working volume of 90 L when growing S. bombicola for SLP production.

[0212] In a preferred embodiment, the nutrients used for SLP production are glucose, urea, yeast extract, canola oil, magnesium sulfate and potassium phosphate.

[0213] Reactors were inoculated with 8 liters of liquid culture grown in flasks. The duration of the culture period for SLP production was 7-8 days at 25 °C and pH 3.5, with sampling performed twice a day.

[0214] The final concentration of SLP is roughly 10% of the working volume, in this case about 9 L of product, which contains 300-400 grams of SLP per liter.

Embodiment 2

[0215] Example 2: Fermentation of Wickhamia and / or Pichia pastoris for sophorolipid production in a 450L dispensable reactor.

[0216]A portable airlift reactor operated by PLC with water filtration, temperature control unit and ventilator for adequate ventilation was used. The method can be performed as a batch culture process. When growing Wickhamia or Pichia pastoris for SLP production, the reactor has a working volume of 400 L.

[0217] In a preferred embodiment, the nutrients used for SLP production are glucose, urea, yeast extract, canola oil, magnesium sulfate and potassium phosphate.

[0218] Inoculation of this reactor required up to 5% liquid seed culture of the working volume. At a temperature of 25° C. and pH 3.5, the duration of the culture period was 7 days, with sampling performed twice a day.

[0219] The final concentration of SLP was approximately 20-25% of the working volume, in which case greater than 90 L of product was formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com