Preparation method of weakly-acidic cation chromatography column packing

A technology for cation chromatography and column packing is applied in the field of preparation of weakly acidic cationic chromatography column packing resin, which can solve the problems of complexity and time-consuming, and achieve the effects of low detection limit, easy operation and short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Pretreatment of polymer microspheres:

[0028] Take 1.0g maleic anhydride (MAH) as a functional monomer, 1.0ml divinylbenzene (DVB) as a crosslinking agent and 0.1ml dicumyl peroxide (DCP) as an initiator and put it into 10.0ml acetone organic solvent, After stirring and dissolving in a 100ml beaker, add 5.0g of PS-DVB polymer microspheres that have been swollen completely with dichloromethane (DCM), and treat them in an ultrasonic or water bath (35°C) for 15 minutes to evaporate most of the solvent and the microspheres After the surface is micro-dried and solidified, the above-mentioned materials are attached to the surface of the microsphere and the surface of the pores inside the microsphere, and then placed in an oven at a constant temperature of 40° C. for 1 hour until the PS-DVB polymer microsphere is dry.

[0029] (2) Graft polymerization of polymer microspheres:

[0030] Place the pretreated polymeric microspheres in an oven, raise the temperature to 170°C,...

Embodiment 2

[0053] The difference from the step (1) of Example 1 is that 1.2g of PBDMAN (polybutadiene-g-maleic anhydride) was used instead of MAH (maleic anhydride) to be dissolved in 10ml of acetone organic solvent, and the others were the same.

[0054] The difference from step (2) of Example 1 is that the temperature is kept at 180° C. for 6 hours in an oven, and the others are the same.

[0055] The difference from step (3) of Example 1 is that 200ml of 0.5mol / M NaOH solution is added, hydrolyzed at 60°C for 2 hours, soaked in 1.0mol / M hydrochloric acid overnight, and then washed with deionized water to obtain Weakly acidic cation column packing.

[0056] Other steps are with embodiment 1.

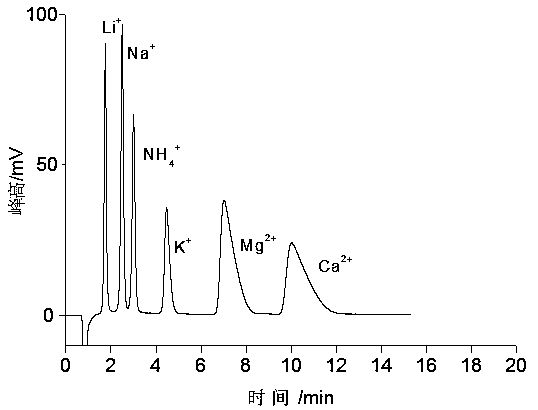

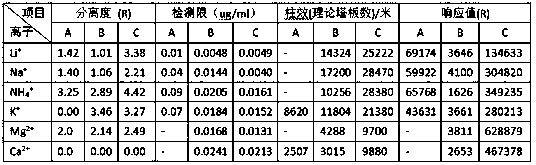

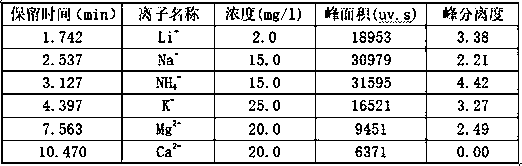

[0057] The separation column made with the weakly acidic cation chromatographic column filler prepared in Example 2, adopts the same sample and test conditions as in Example 1, and simultaneously separates and detects alkali metals, ammonium and alkaline earth metals in the sample, and the data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com