A preparation method of silicon oxide-based negative electrode material for lithium ion battery

A silicon oxide-based, lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as unfavorable industrialization, rapid capacity decline, and long and complicated preparation, and achieve good carbon coating effect. , Good application prospect, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

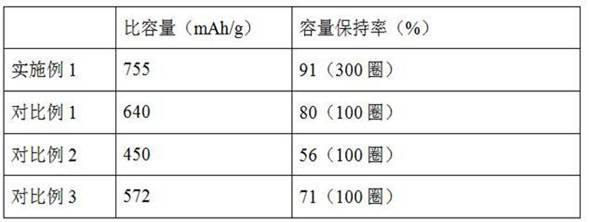

Embodiment 1

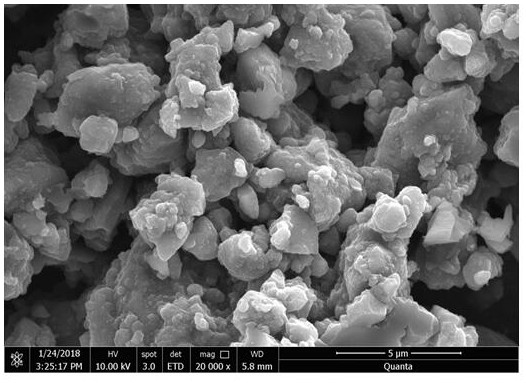

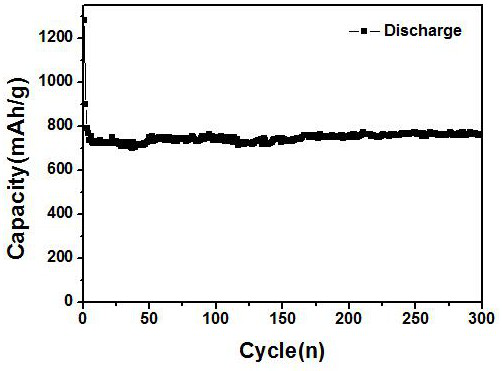

[0027]The preparation method of the silicon oxide-based negative electrode material of the lithium ion battery of this embodiment includes the following steps:

[0028](1) Weigh 8 g of ethyl orthosilicate and add it to 15 ml of absolute ethanol, stir evenly to form an ethanol solution of ethyl orthosilicate, measure 5 ml of deionized water and add to the ethanol solution of ethyl orthosilicate After stirring for 1 h, add concentrated hydrochloric acid, adjust pH=5, and stir for 10 min to obtain a sol;

[0029](2) Add 2 ml of hydrogen peroxide as a loosening agent to the sol, continue stirring for 30 minutes, weigh 2.5 g of sucrose and dissolve in the above sol, stir vigorously until the sucrose is fully dissolved, and continue stirring for 30 minutes to make it uniformly dispersed. Then it is heated and stirred with magnetic force at 90°C until the solvent is completely volatilized, and then ground with a mortar for uniform treatment to obtain silica / carbon precursor powder;

[0030](3) Fina...

Embodiment 2

[0033]The preparation method of the silicon oxide-based negative electrode material of the lithium ion battery of this embodiment includes the following steps:

[0034](1) Weigh 8 g of tetramethyl orthosilicate and add it to 15 ml of isopropanol, stir evenly to form a solution of tetramethyl orthosilicate in isopropanol. Measure 10 ml of deionized water and add it to the ethanol solution of tetramethyl orthosilicate. After stirring for 1 h, add concentrated hydrochloric acid, adjust pH=4, and stir for 10 min to obtain a sol;

[0035](2) Add 4 ml of hydrogen peroxide to the sol, as a loosening agent, continue to stir for 30 min, weigh 5 g of sucrose and dissolve in the above sol, stir vigorously until the sucrose is fully dissolved, continue to stir for 40 min to make it uniformly dispersed, and then Magnetic heating at 95°C and stirring until the solvent is completely volatilized, grind uniformly with a mortar, and obtain silica / carbon precursor powder;

[0036](3) Heat the powder at 900℃ in...

Embodiment 3

[0039]The preparation method of the silicon oxide-based negative electrode material of the lithium ion battery of this embodiment includes the following steps:

[0040](1) Weigh 8 g of ethyl orthosilicate and add it to 20 ml of glycerol, stir evenly to form a glycerol solution of ethyl orthosilicate. Measure 16 ml of deionized water and add it to the glycerol solution of ethyl orthosilicate. After stirring for 1 h, add nitric acid, adjust the pH to 4, and stir for 10 min to obtain a sol.

[0041](2) Add 10ml of hydrogen peroxide to the sol as a loosening agent and continue to stir for 30 min. Weigh 8 g of sucrose and dissolve in the above sol, stir vigorously until the sucrose is fully dissolved, and continue to stir for 40 min to make it uniformly dispersed. Then, it is heated and stirred with magnetic force at 95°C until the solvent is completely volatilized, and then ground with a mortar for uniform treatment to obtain silica / carbon precursor powder.

[0042](3) Heat the powder at 800℃ in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com