Mono-dispersed particle-size-controllable nanometer yttrium stabilized zirconia powder, preparation method and applications thereof

A zirconia powder and yttrium stabilization technology, applied in the field of zirconia powder and its preparation, can solve the problems of product morphology, crystal phase and particle size being difficult to control, complex precursor preparation system, etc., achieving a wide range of concentrations and mild conditions. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

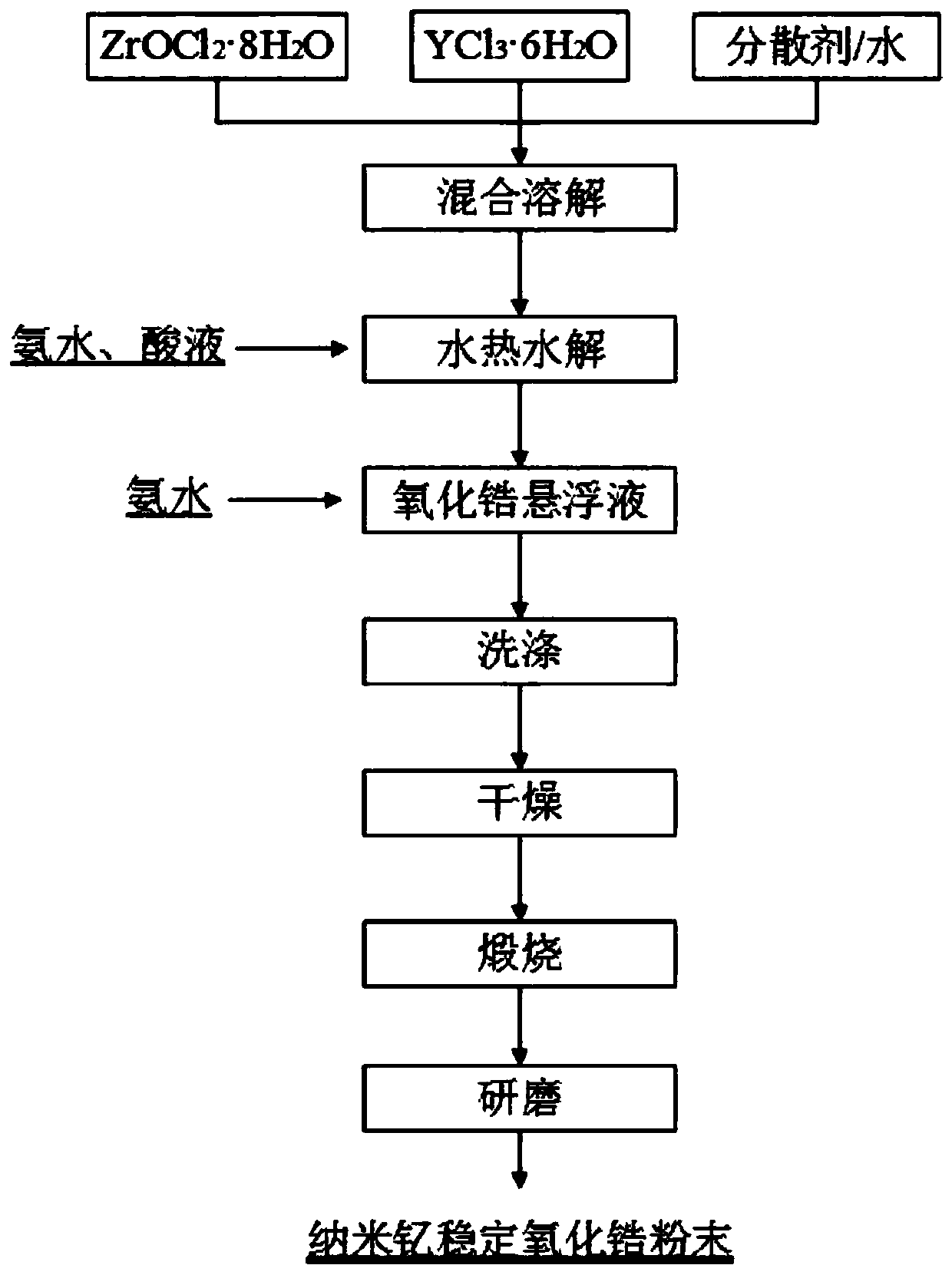

[0044] A preparation method of nano-yttrium stabilized zirconia powder with controllable monodisperse particle size, the preparation method comprises the following steps:

[0045] (1) Reaction solution preparation method: prepare zirconium oxychloride, yttrium chloride, dispersant raw material solution, Zr 4+ with Y 3+ The molar concentration ratio is 99:2~90:20;

[0046] (2) Hydrothermal hydrolysis process: Transfer the reaction solution obtained in step (1) to a polytetrafluoroethylene-lined stainless steel homogeneous reaction kettle, heat up to 120-300°C for 3-20 hours of hydrothermal reaction, during the reaction process , under the condition of high-speed stirring 300-10000r / min, the concentration of 0.5-6mol / L ammonia solution or 0.1-3mol / L acid solution is added through the atomizer at 1-10000mL / min to adjust the raw material solution H + Concentration, so that Zr in the solution 4+ Partial hydrolysis to generate crystal nuclei, adjust the solution H + The concentr...

Embodiment 1

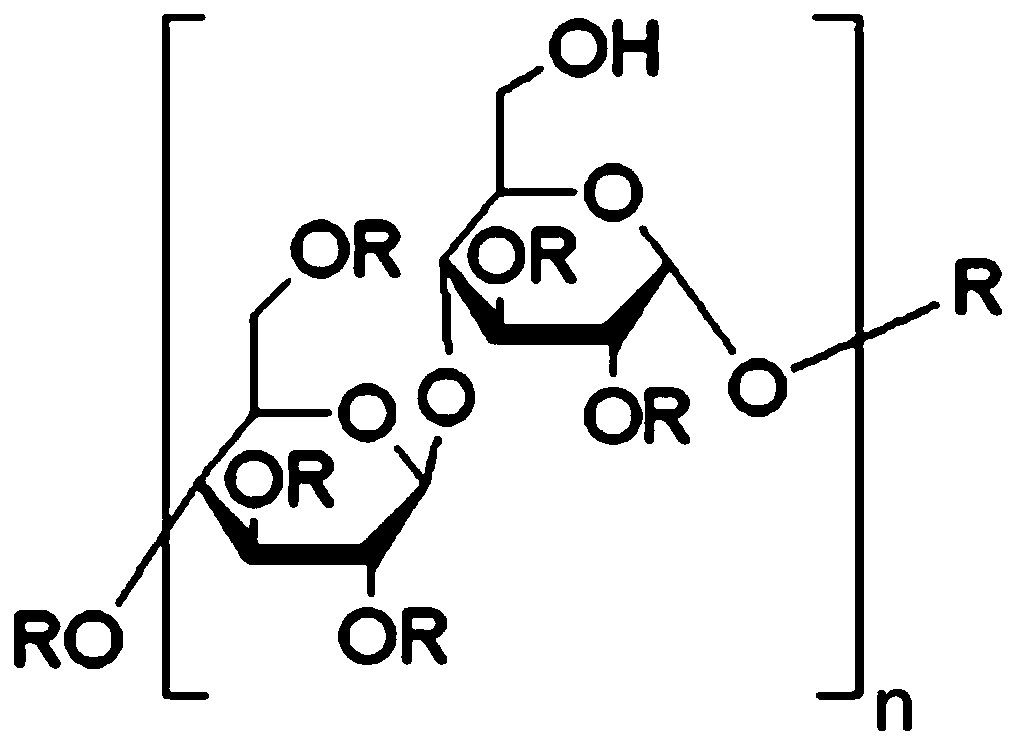

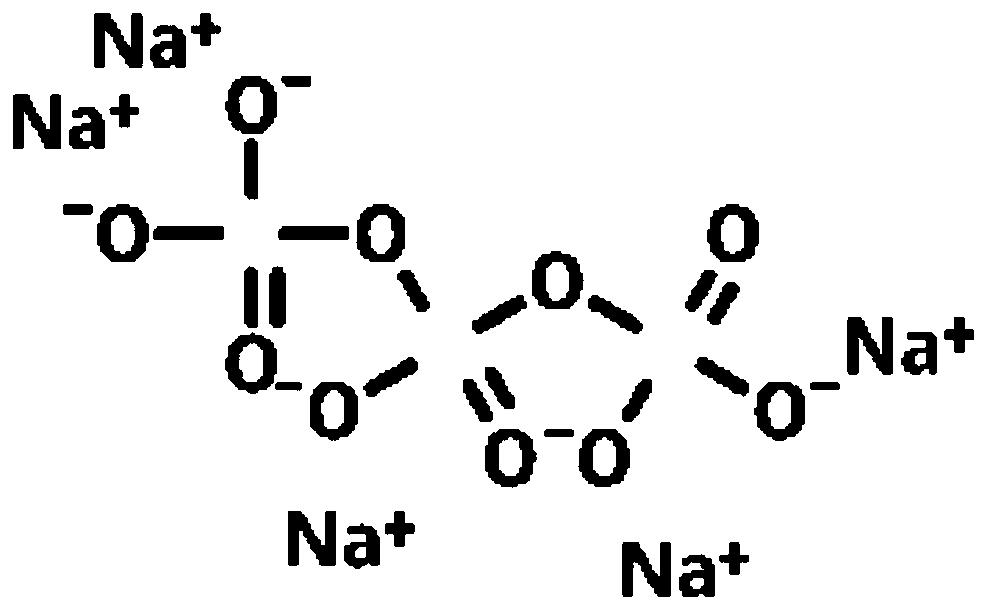

[0051] (1) Preparation of ZrOCl 2 , YCl 3 , dispersant mixed solution, wherein, hydroxypropyl methyl cellulose, hydroxypropyl cellulose, sodium tripolyphosphate are composed in equal proportions, Zr 4+ :Y 3+ The molar ratio is 97:6;

[0052] (2) Transfer the solution obtained in step (1) to a polytetrafluoroethylene-lined stainless steel reactor, heat it to 180°C for hydrothermal hydrolysis, and during the hydrothermal hydrolysis process, stir at 500r / min, by adding 3.85mol / L dilute ammonia solution to adjust the H of the final reaction solution + concentration, so that the solution final C Zr 4+ =0.6mol / L, H + The concentration is 0.1mol / L, the concentration of the dispersant is 1g / L, after 12 hours of reaction, cool to obtain a hydrated zirconia suspension;

[0053] (3) Add 10% ammonia water to the hydrated zirconia suspension at 60°C and 500r / min at 10mL / min to make Y 3+ Uniformly precipitate on the surface of hydrated zirconia particles, stop adding ammonia water w...

Embodiment 2

[0056] (1) Preparation of ZrOCl 2 , YCl 3 , hydroxypropyl cellulose mixed solution, wherein Zr 4+ :Y 3+ The molar ratio is 97:6;

[0057] (2) Transfer the solution obtained in step (1) to a polytetrafluoroethylene-lined stainless steel reactor, heat it to 180°C for hydrothermal hydrolysis, and during the hydrothermal hydrolysis process, stir at 500r / min, by adding 3.15mol / L dilute ammonia solution to adjust the H of the final reaction solution + concentration, so that the solution final C Zr 4+ =0.6mol / L, H + Concentration is 0.3mol / L, hydroxypropyl cellulose concentration is 1g / L, cools after reacting for 12h to obtain hydrated zirconia suspension;

[0058] (3) Add 10% ammonia water to the hydrated zirconia suspension at 60°C and 500r / min at 10mL / min to make Y 3+ Precipitate uniformly on the surface of hydrated zirconia particles, stop adding ammonia water when the pH of the suspension is > 9, obtain the suspension after yttrium precipitation, statically age for 12 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com