Activated carbon/zirconium-manganese oxide composite material, method for preparing same and application of activated carbon/zirconium-manganese oxide composite material

A technology of manganese oxide and composite materials, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problem that the adsorption capacity is not as expected, achieve low investment, realize large-scale batch production, and reduce agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

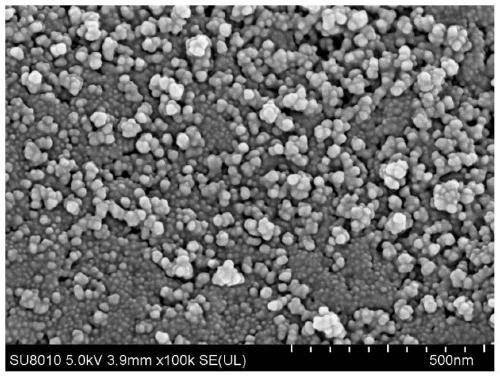

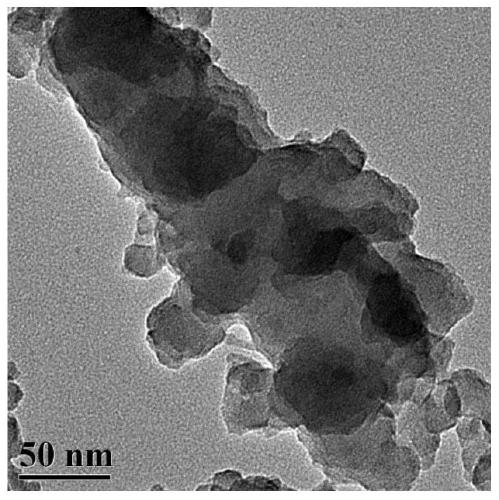

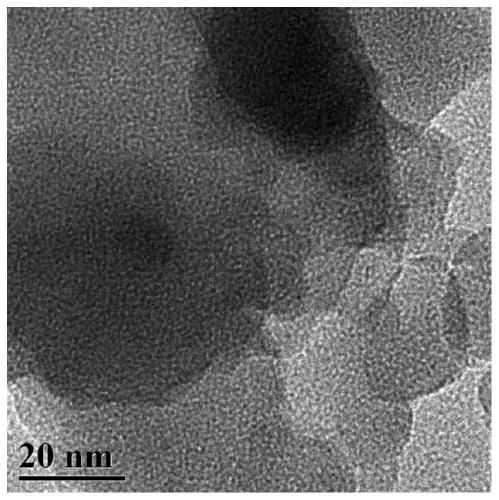

Image

Examples

Embodiment 1

[0042] (1) Dissolve 88mg of activated carbon solid in 15ml of deionized water and 15ml of absolute ethanol mixture, and sonicate for 1 hour;

[0043] (2) Add 500 mg of zirconium oxychloride solid to the mixed solution obtained in step (1), continue stirring, and continue to add 524.5 mg of manganese sulfate solid to obtain a mixed solution;

[0044] (3) Add 0.5ml of 4mol / L sodium hydroxide solution dropwise into the mixed solution obtained in step (2), and keep stirring;

[0045] (4) Add 0.5ml of 30% (mass ratio) hydrogen peroxide solution dropwise into the mixed solution obtained in step (3), and after continuous stirring, ultrasonicate for 1 hour;

[0046] (5) Put the solution obtained in step (4) into a high-temperature reaction kettle, seal it, and place it in an oven at 180°C for 0.5h;

[0047] (6) After the reactants in step (5) are cooled to room temperature, they are centrifuged and washed, then dried in an oven at 60°C for 12 hours, ground, and passed through a 60-me...

Embodiment 2

[0055] (1) Dissolve 176mg of activated carbon solid in 15ml of deionized water and 15ml of absolute ethanol mixture, and sonicate for 2 hours;

[0056] (2) Add 500 mg of zirconium oxychloride solid to the mixed solution obtained in step (1), continue stirring, and continue to add 262.3 mg of manganese sulfate solid to obtain a mixed solution;

[0057] (3) Add 1ml of 4mol / L sodium hydroxide solution dropwise into the mixed solution obtained in step (2), and keep stirring;

[0058] (4) Add 1ml of 30% hydrogen peroxide solution dropwise into the mixed solution obtained in step (3), after continuous stirring, ultrasonic treatment for 2 hours;

[0059] (5) Put the solution obtained in step (4) into a high-temperature reactor, seal it, and place it in an oven at 150°C for 1 hour;

[0060] (6) After the reactants in step (5) are cooled to room temperature, they are centrifuged and washed, then dried in an oven at 60°C for 12 hours, ground, and passed through a 60-mesh sieve to obtai...

Embodiment 3

[0068] (1) Dissolve 44mg of activated carbon solid in 15ml of deionized water and 15ml of absolute ethanol mixture, and sonicate for 1 hour;

[0069] (2) Add 500 mg of zirconium oxychloride solid to the mixed solution obtained in step (1), continue stirring, and continue to add 524.5 mg of manganese sulfate solid to obtain a mixed solution;

[0070] (3) Add 1ml of 5mol / L sodium hydroxide solution dropwise into the mixed solution obtained in step (2), and keep stirring;

[0071] (4) Add 1ml of 30% hydrogen peroxide solution dropwise into the mixed solution obtained in step (3), after continuous stirring, ultrasonic treatment for 2 hours;

[0072] (5) Put the solution obtained in step (4) into a high-temperature reactor, seal it, and place it in an oven at 150°C for 12 hours;

[0073] (6) After the reactants in step (5) are cooled to room temperature, they are centrifuged and washed, then dried in an oven at 50°C for 12 hours, ground, and passed through a 200-mesh sieve to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com