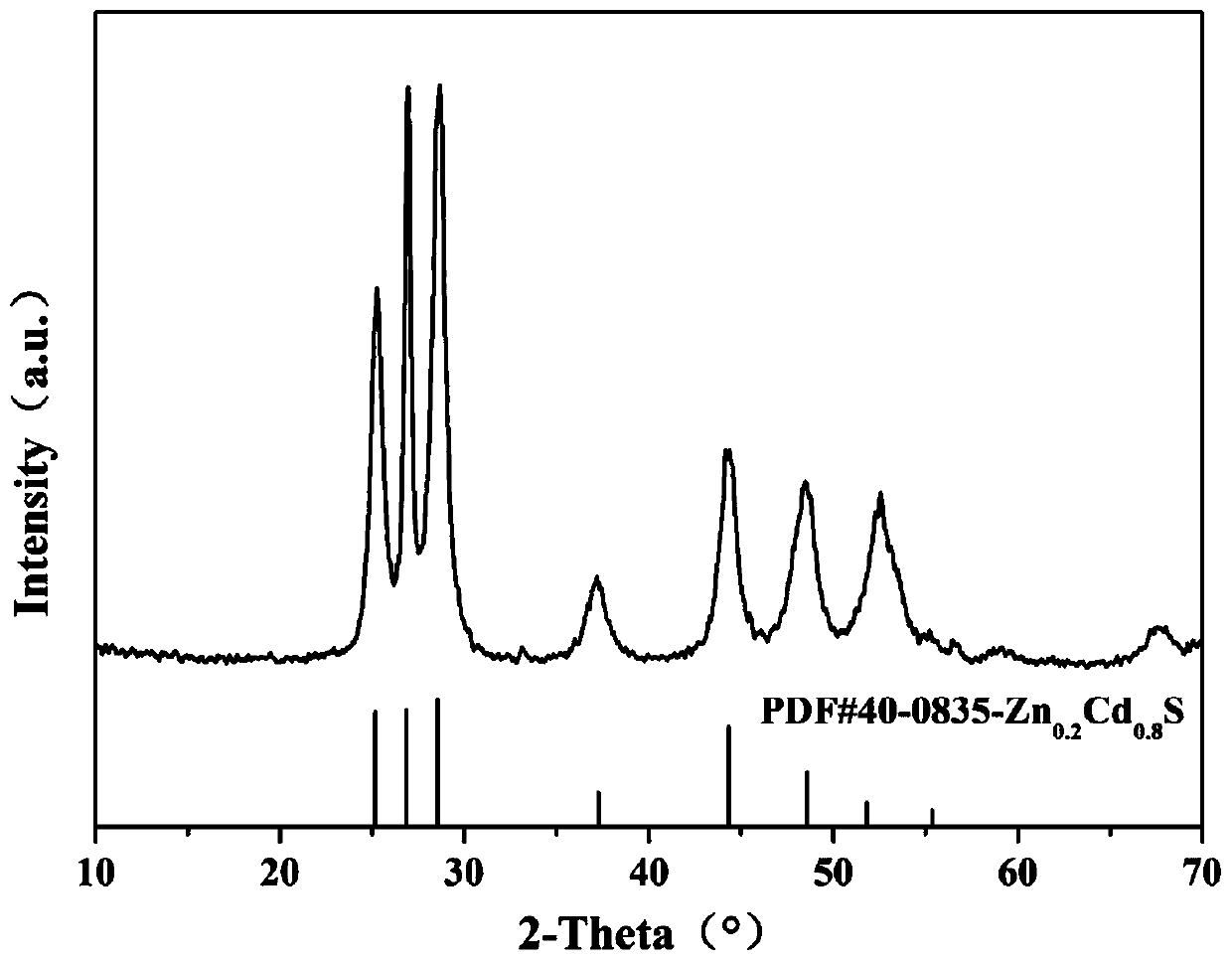

Two-step method for preparing Zn0.2Cd0.8S/rGO composite material

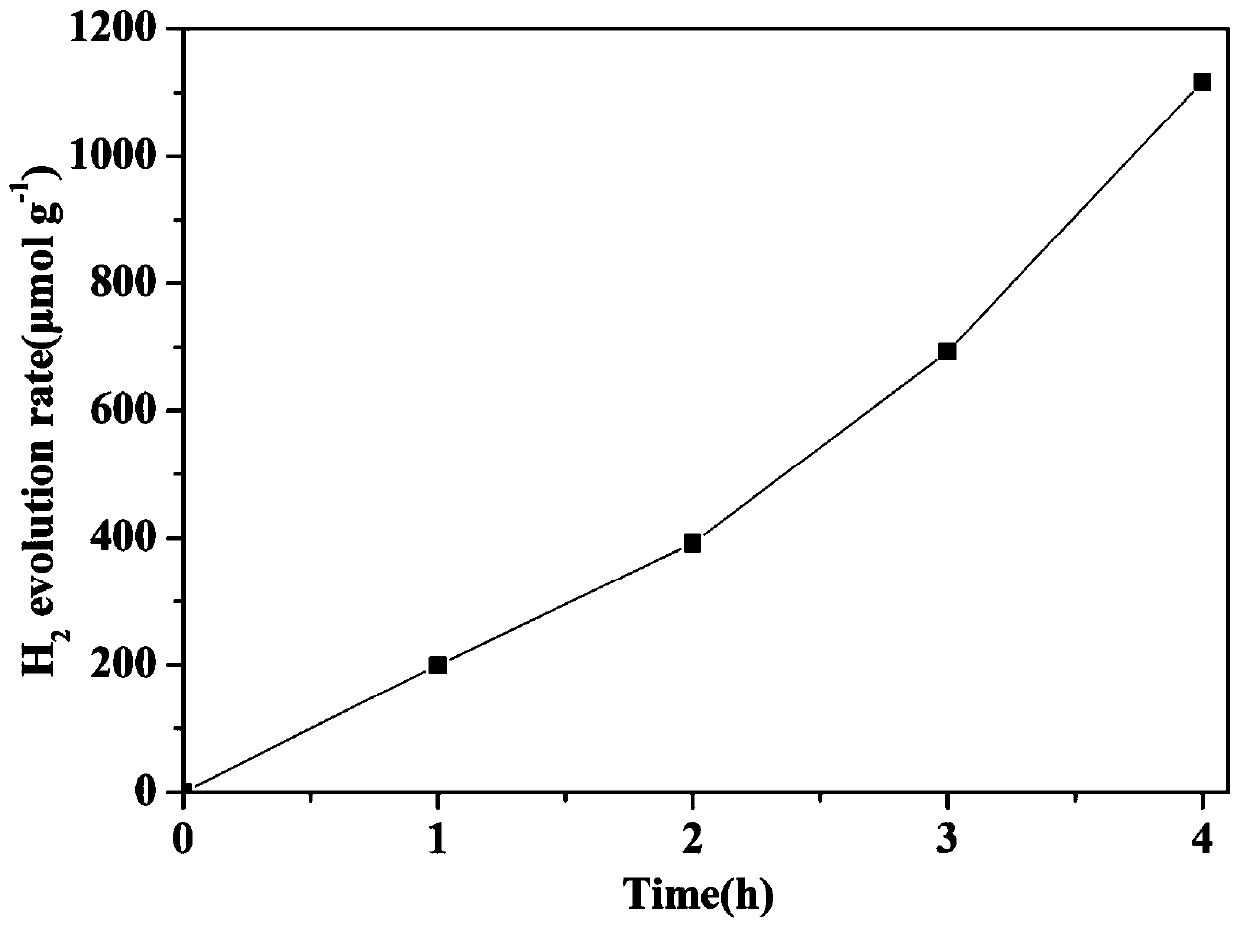

A composite material, step-by-step technology, applied in the fields of nanotechnology, chemical instruments and methods, chemical/physical processes, etc. for materials and surface science, can solve the problems of increased cost, difficult control of reaction rate, and uncontrollable reaction, etc. Achieve good economic and social benefits, stabilize photocatalytic performance, and expand the effect of light response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Take 5mL of ethylenediamine (EN) and add 20mL of deionized water to magnetically stir for 20min and ultrasonically disperse for 15min to form a mixed solution A;

[0032] Step 2: Get 0.2mmol of zinc acetate dihydrate (Zn(Ac) 2 2H 2 O) and 0.8 mmol of cadmium nitrate tetrahydrate (Zn(NO 3 )2 4H 2 O) add magnetic stirring in mixed solution A for 20min, and ultrasonically disperse for 15min to make mixed solution B;

[0033] Step 3: Take 2 mmol of L-cysteine as a sulfur source, add it to the mixed solution B for magnetic stirring for 20 minutes, and ultrasonically disperse for 15 minutes to form a mixed solution C;

[0034] Step 4: Add the mixed solution C to the lining of polytetrafluoroethylene, control the filling ratio to 25%, and react at 160°C for 8 hours;

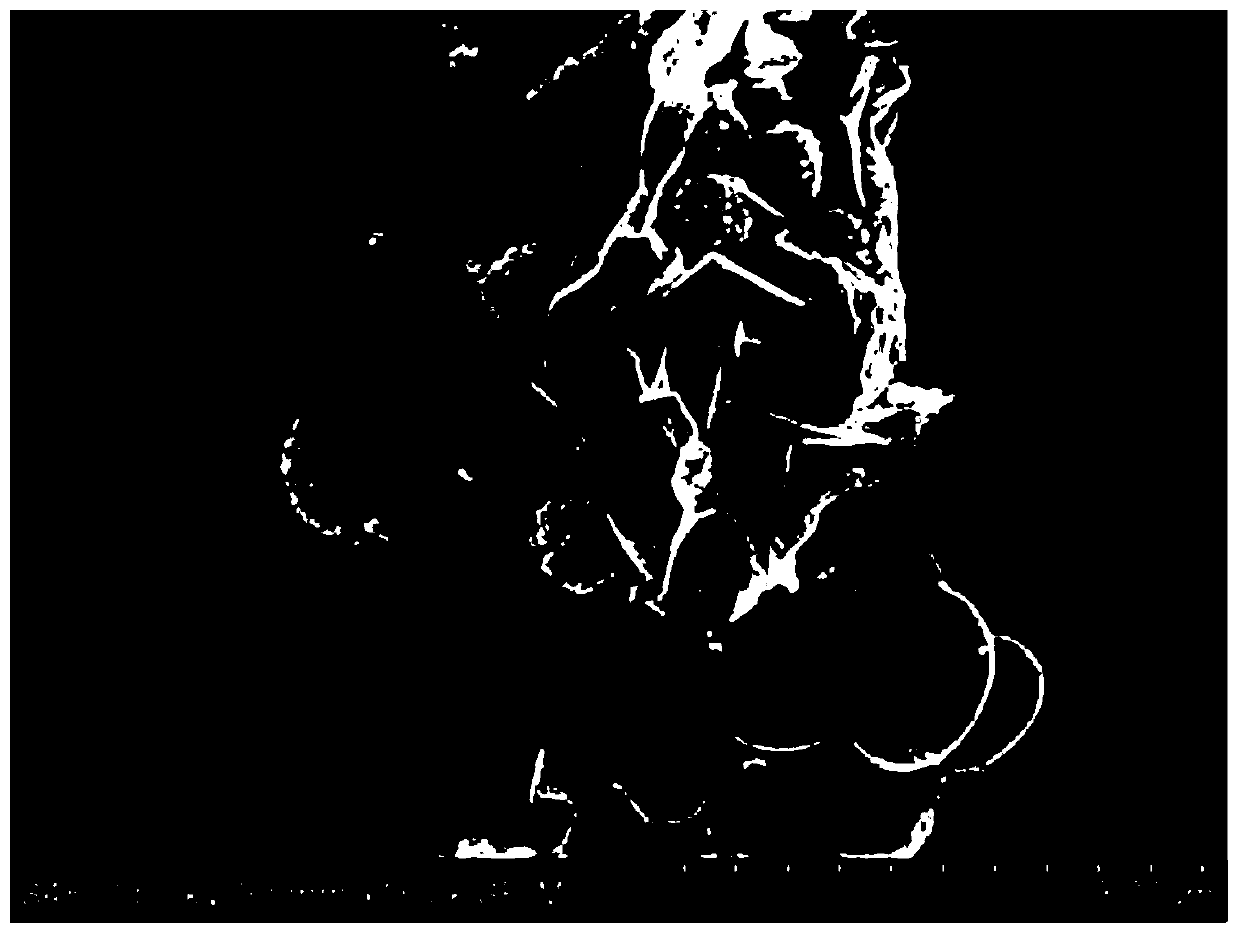

[0035] Step 5: After the reaction is completed, centrifuge and wash 3 times with deionized water and ethanol respectively, dry in vacuum at 60°C for 6 hours, and then grind to obtain Zn 0.2 Cd 0.8...

Embodiment 2

[0041] Step 1: Take 10 mL of ethylenediamine (EN) and add 40 mL of deionized water to magnetically stir for 30 minutes, and ultrasonically disperse for 30 minutes to form a mixed solution A;

[0042] Step 2: Get 0.3mmol of zinc acetate dihydrate (Zn(Ac) 2 2H 2 O) and 1.2 mmol of cadmium nitrate tetrahydrate (Zn(NO 3 ) 2 4H 2 O) adding magnetic stirring in mixed solution A for 30min, ultrasonic dispersion for 30min to make mixed solution B;

[0043] Step 3: Take 3 mmol of L-cysteine as a sulfur source, add it to the mixed solution B for magnetic stirring for 30 minutes, and ultrasonically disperse for 30 minutes to form a mixed solution C;

[0044] Step 4: Add the mixed solution C to the lining of polytetrafluoroethylene, control the filling ratio to 50%, and react at 200°C for 12 hours;

[0045] Step 5: After the reaction is completed, centrifuge and wash 4 times with deionized water and ethanol respectively, dry in vacuum at 80°C for 8 hours, and grind to obtain Zn 0....

Embodiment 3

[0052] Step 1: Take 8mL of ethylenediamine (EN) and add 30mL of deionized water to magnetically stir for 40min and ultrasonically disperse for 20min to form a mixed solution A;

[0053] Step 2: Get 0.4mmol of zinc acetate dihydrate (Zn(Ac) 2 2H 2 O) and 1.6 mmol of cadmium nitrate tetrahydrate (Zn(NO 3 ) 2 4H 2 O) add magnetic stirring in mixed solution A for 40min, and ultrasonically disperse for 20min to make mixed solution B;

[0054] Step 3: Take 4 mmol of L-cysteine as a sulfur source, add it to the mixed solution B for magnetic stirring for 40 minutes, and ultrasonically disperse it for 20 minutes to form a mixed solution C;

[0055] Step 4: Add the mixed solution C to the lining of polytetrafluoroethylene, control the filling ratio to 38%, and react at 180°C for 10 hours;

[0056] Step 5: After the reaction is completed, centrifuge and wash 5 times with deionized water and ethanol respectively, dry in vacuum at 70°C for 10 hours, and grind to obtain Zn 0.2 Cd 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com