An ultrasonic-assisted microstructure selective forming manufacturing device and method based on digital light

An ultrasonic-assisted, device-manufacturing technology, applied in microstructure devices, manufacturing microstructure devices, microstructure technology, etc., can solve the problems of lack of control methods and devices for three-dimensional microstructure forming areas, and achieve fast response speed and high control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

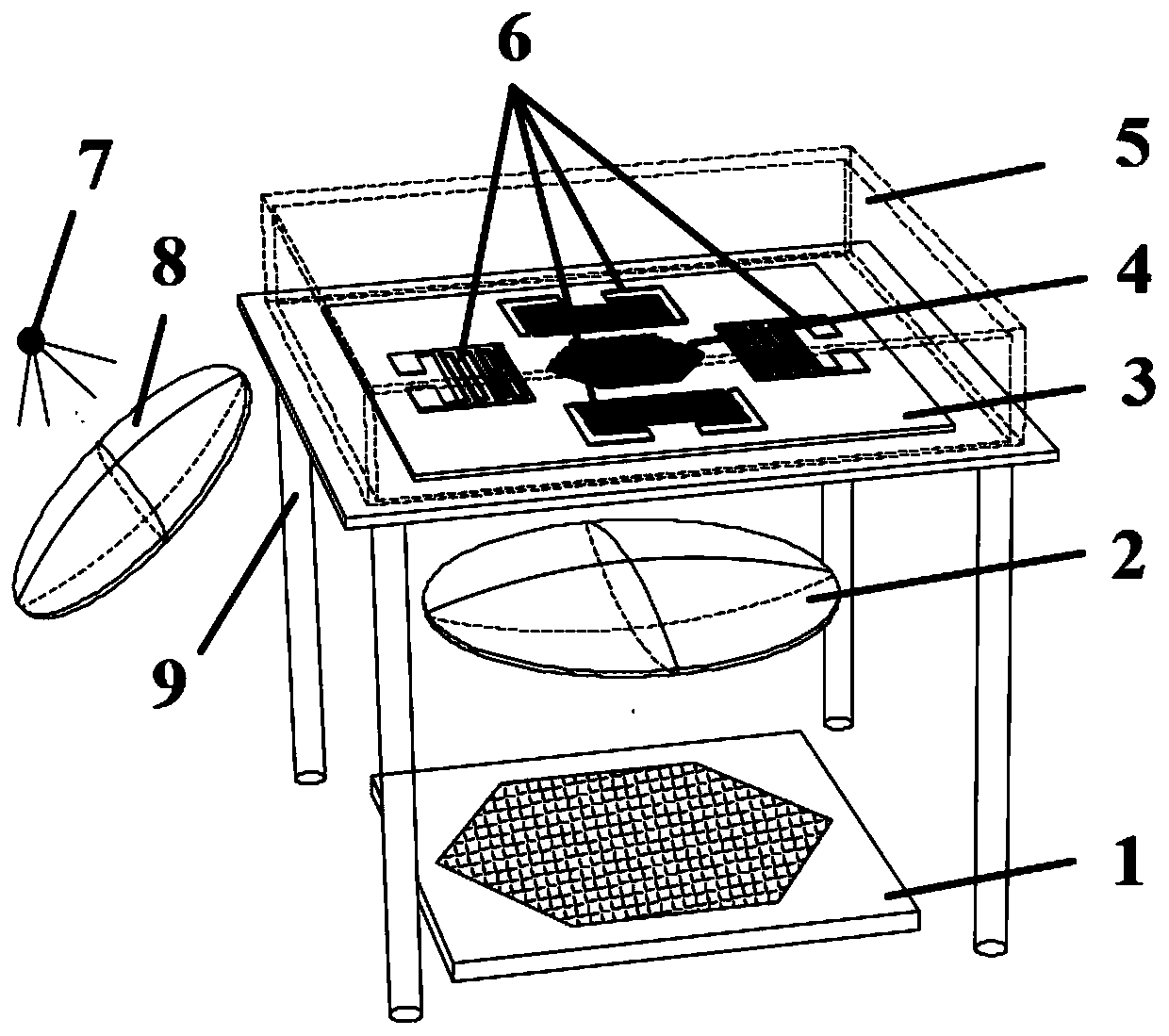

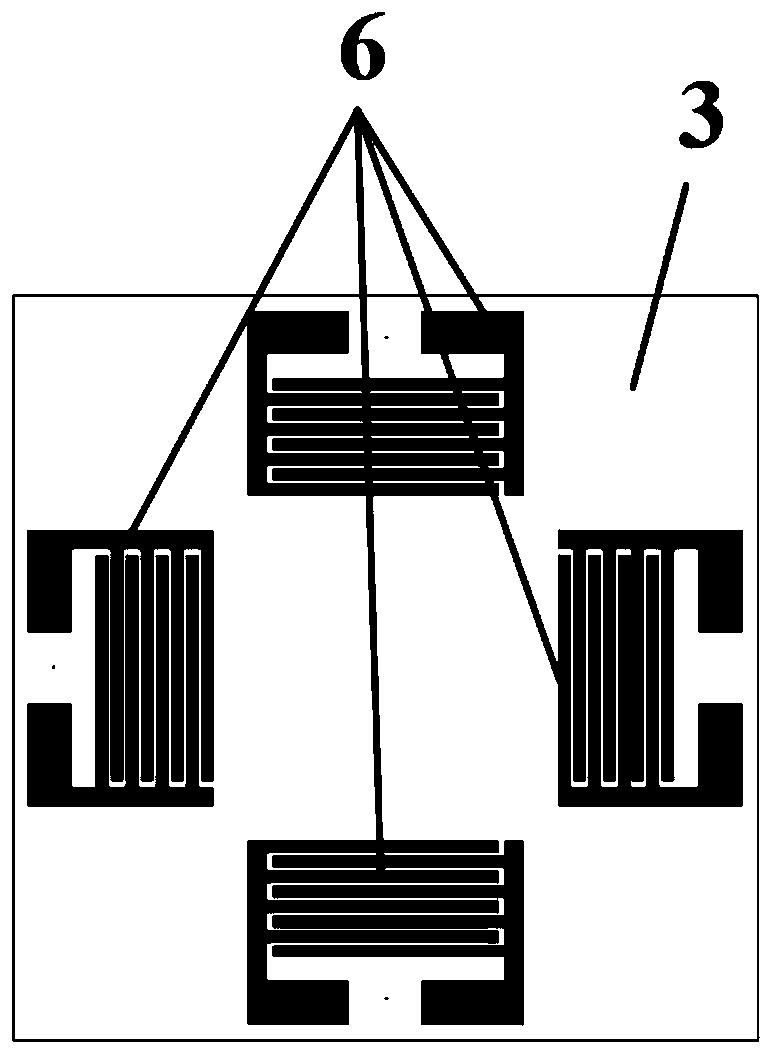

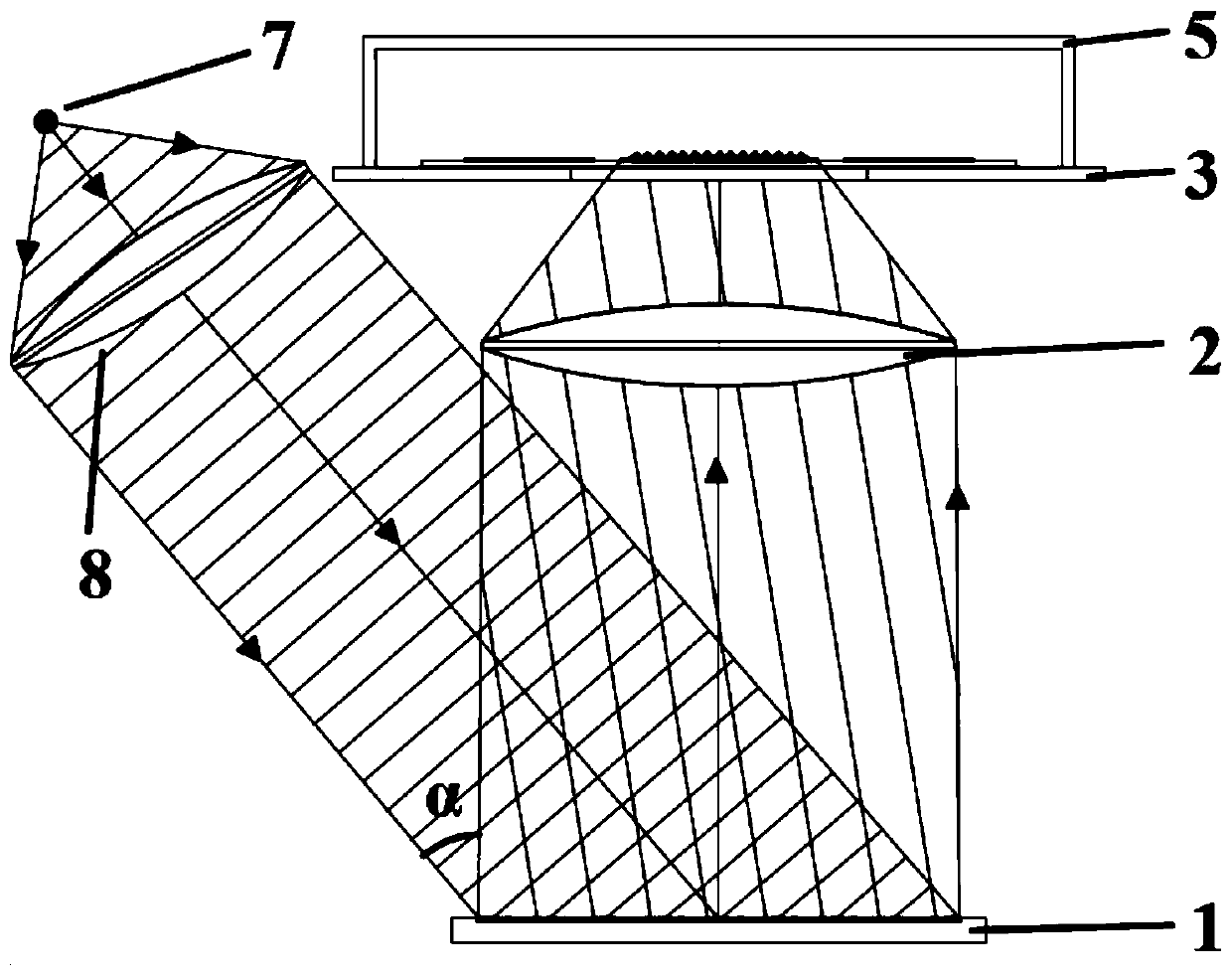

[0049] Such as Figure 4 As shown, this embodiment is a schematic diagram of the implementation results of turning on two pairs of transducers and using a hexagonal digital mask.

[0050] Step 1) Apply a photosensitive liquid 4 on the double-sided polished lithium niobate wafer 3 with a micropipette, so that the photosensitive liquid 4 evenly covers the central area of the double-sided polished lithium niobate wafer 3, and convert the two pairs of fingers The signal generator is connected with the signal generator, the signal generator is started, and the interdigital transducer 6 uses the inverse piezoelectric effect to generate a stable acoustic surface standing wave field on the double-sided polished lithium niobate wafer 3, and the acoustic surface standing wave field is coupled into the photosensitive In the liquid 4, the photosensitive liquid 4 is subjected to the acoustic radiation force in the two-dimensional acoustic surface standing wave field to generate periodic ...

Embodiment 2

[0055] Such as Figure 5 As shown, this embodiment is a schematic diagram of the implementation result of turning on a pair of transducers and using an arrayed circular digital mask.

[0056] Step 1) Coating the photosensitive liquid 4 on the double-sided polished lithium niobate wafer 3 with a micropipette, so that the photosensitive liquid 4 evenly covers the central area of the double-sided polished lithium niobate wafer 3, and transducing a pair of fingers The signal generator is connected to the signal generator, the signal generator is started, and the interdigital transducer 6 uses the inverse piezoelectric effect to generate the acoustic surface standing wave field on the double-sided polished lithium niobate wafer 3, and the acoustic surface standing wave field is coupled into the photosensitive liquid In 4 , the photosensitive liquid 4 is subjected to the acoustic radiation force in the acoustic surface standing wave field to generate periodic microstructure patter...

Embodiment 3

[0060] Such as Image 6 As shown, this embodiment is a schematic diagram of the implementation results of turning on two pairs of transducers, using an arrayed circular digital reticle and a square digital reticle at the same time, and combining the secondary exposure.

[0061] Step 1) Coating a photosensitive liquid 4 on the double-sided polished lithium niobate wafer 3, connecting two pairs of interdigital transducers to the signal generator, starting the signal generator, and the interdigital transducer 6 is polished on both sides of the niobate The acoustic surface standing wave field generated on the lithium wafer 3 is coupled into the photosensitive liquid 4 , thereby forming a corrugated microstructure array on the surface of the photosensitive liquid 4 .

[0062] Step 2) Place the PDMS nitrogen protective shell 5 above the two pairs of interdigital transducers 6, and pass nitrogen gas into the PDMS nitrogen protective shell 5 to exhaust the air. After the microstructur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com