A strain of Acetobacter pasteurii used to convert ethanol to acetic acid and its application in fruit vinegar brewing

A technology based on Acetobacter pasteuriani and ethanol, which is applied in the food, beverage and biological fields, can solve the problems of poor flavor of fruit vinegar, insufficient acid production ability and alcohol resistance, and achieve high nutritional value, aroma and taste, and good alcohol tolerance Effects of sex, high flavonoid content and flavor content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

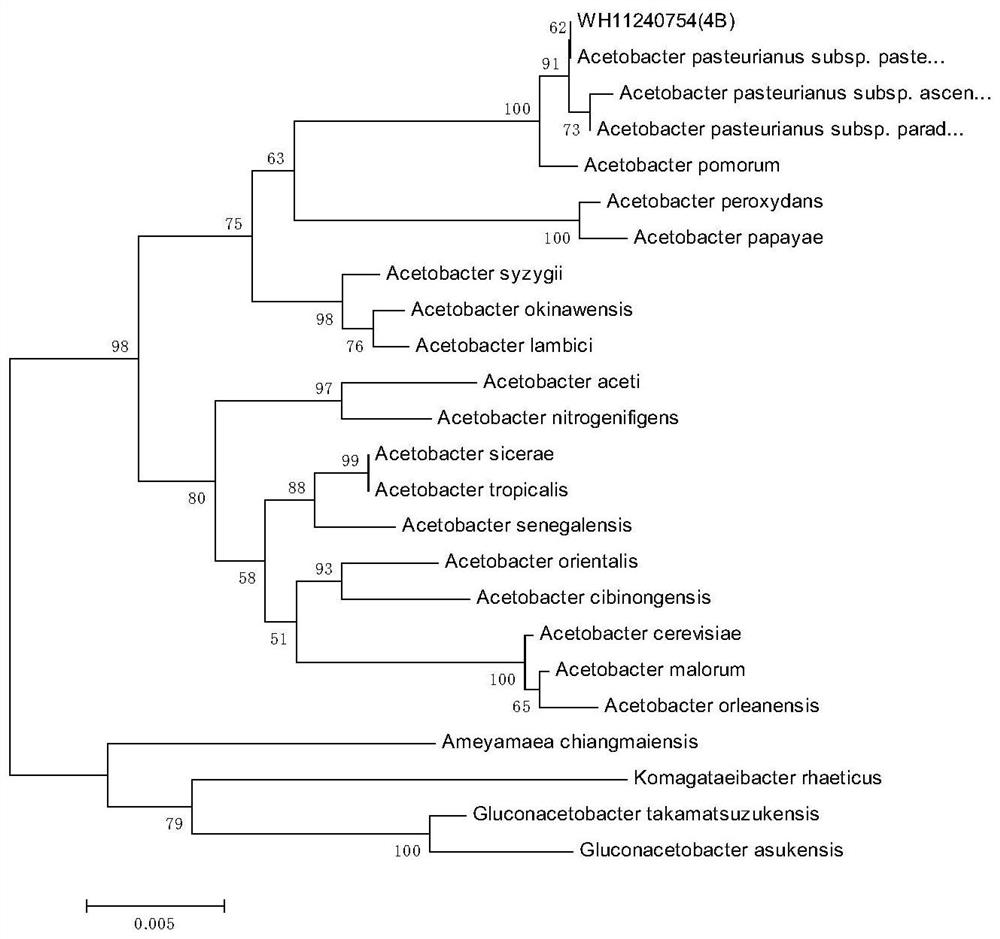

[0022] The separation and identification of embodiment 1 acetic acid bacteria

[0023] (1) Isolation of acetic acid bacteria

[0024] Take the original vinegar of orange vinegar for 10 times and 100 times of gradient concentration dilution, apply the original vinegar and the diluted original vinegar on the plate poured with the solid separation medium of acetic acid bacteria, apply three plates for each gradient, and place it upside down at a constant temperature Incubate at 30°C for 3 days in an incubator.

[0025] (2) Screening of acetic acid bacteria

[0026] Select a plate with good colony separation, pick multiple single colonies on the plate, respectively streak the plate, and then place them in an incubator at 30°C for 3 days, pick a single colony, and inoculate the same colony in the acetic acid bacteria liquid medium And in the preliminary identification medium with ethanol, after culturing in a shaker at 30°C and 150rpm for two days, if the medium containing ethano...

Embodiment 2

[0036] The brewing of embodiment 2 jujube fruit vinegar

[0037] 1) Enzymolysis: get red jujube meat, add 6 times the water of weight, beating with a juice extractor, then add the mixed enzyme of 0.24% cellulase and pectinase by weight in fruit pulp (cellulase: pectinase The mass ratio of the enzyme is 2:1), and after stirring, it is enzymolyzed at room temperature for 2 hours to obtain jujube pulp.

[0038] 2) Alcoholic fermentation: add Saccharomyces cerevisiae into jujube pulp at a ratio of 300mg / L, mix well, seal, and then place in a constant temperature incubator at 28°C for anaerobic fermentation. During the fermentation process, samples were taken regularly, and after the samples were processed at 5000rpm for 5 minutes, the content of reducing sugar in the fermentation broth was measured by the 3,5-dinitrosalicylic acid method. When the reducing sugar content no longer decreased significantly, the fermentation was terminated, and alcohol was obtained after filtration. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com