Bovine bone collagen peptide and production method thereof

A collagen peptide and collagen peptide technology, which is applied in the field of collagen peptides, can solve the problems of complicated operation, easy moisture absorption and caking, and high energy consumption at the optimum enzymatic hydrolysis temperature, and achieves simplified process steps and less moisture absorption. The effect of caking and improving water resolubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

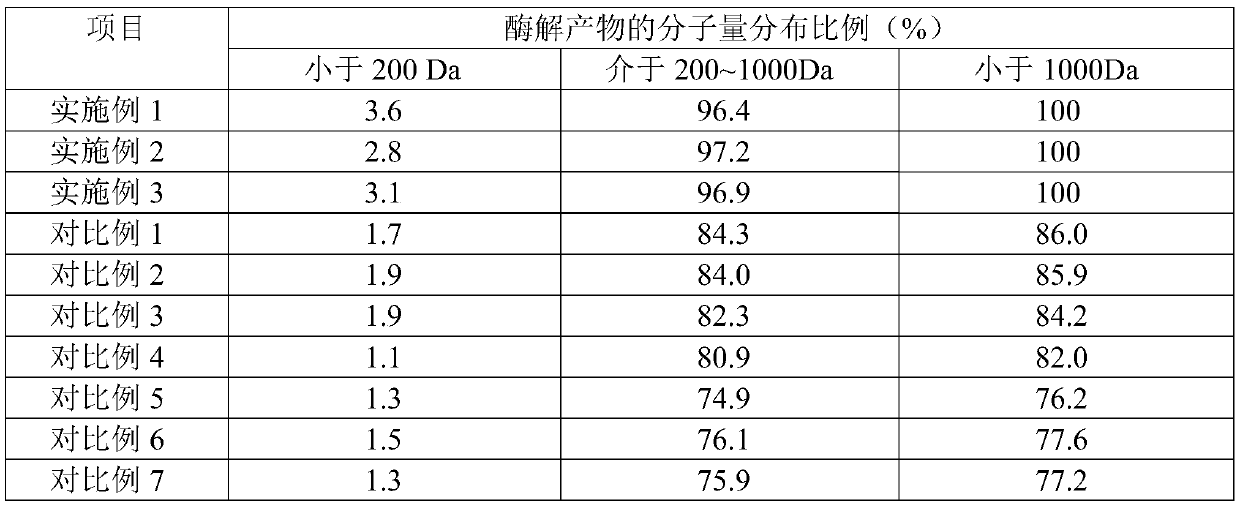

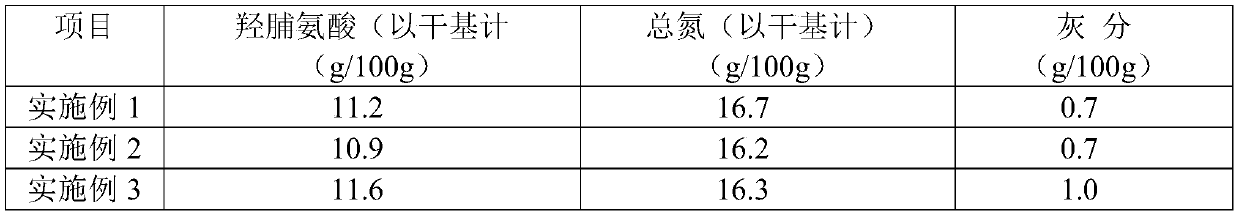

Examples

Embodiment 1

[0047] (1) Pre-treatment of raw materials: first remove the impurities on the fresh beef bones manually, and then use a bone crusher to crush them into 2-3cm bone pieces, then clean the crushed beef bones, and then put them into the cooking tank and adding water for cooking, wherein the volume ratio of bovine bone and water is 1:3, the cooking temperature is 100° C., the cooking pressure is 2 MPa, and the cooking time is 4 hours to obtain a cooking liquid.

[0048] (2) Oil-water separation: the cooking liquid is separated from oil and water by gravity separation, and the temperature of the obtained water phase is lowered to 50-55° C. to obtain a crude collagen solution.

[0049] (3) Enzymolysis: Add 0.1% (w / w) high-efficiency compound enzyme preparation of raw material weight to the crude collagen solution, mix evenly, and enzymolyze for 1 hour to obtain a collagen peptide solution. Wherein, the high-efficiency compound enzyme preparation is composed of the following component...

Embodiment 2

[0055] (1) Pre-treatment of raw materials: first remove the impurities on the fresh beef bones manually, and then use a bone crusher to crush them into 2-3cm bone pieces, then clean the crushed beef bones, and then put them into the cooking tank and adding water for cooking, wherein the volume ratio of bovine bone and water is 1:4, the cooking temperature is 110° C., the cooking pressure is 1 MPa, and the cooking time is 3 hours to obtain a cooking liquid.

[0056] (2) Oil-water separation: the cooking liquid is separated from oil and water by mechanical separation, and the temperature of the obtained water phase is lowered to 50-55° C. to obtain a crude collagen solution.

[0057] (3) Enzymolysis: Add 0.1% (w / w) high-efficiency compound enzyme preparation of raw material weight to the crude collagen solution, mix evenly, and enzymolyze for 1 hour to obtain a collagen peptide solution. Wherein, the high-efficiency compound enzyme preparation is composed of the following compon...

Embodiment 3

[0063] (1) Pre-treatment of raw materials: first remove the impurities on the fresh beef bones manually, then use a bone crusher to crush them into 2-3cm bone pieces, then clean the crushed beef bones, and then put them into steaming Add water to the tank for cooking, wherein the volume ratio of beef bones to water is 1:5, the cooking temperature is 120°C, the cooking pressure is 0.15MPa, and the cooking time is 2h to obtain a cooking liquid.

[0064] (2) Oil-water separation: the cooking liquid is separated from oil and water by centrifugation, and the temperature of the obtained water phase is lowered to 50-55° C. to obtain a crude collagen solution.

[0065] (3) Enzymolysis: Add 0.1% (w / w) high-efficiency compound enzyme preparation of raw material weight to the crude collagen solution, mix evenly, and enzymolyze for 1 hour to obtain a collagen peptide solution. Wherein, the high-efficiency compound enzyme preparation is composed of the following components in mass percenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com