A 3D printing positive photoresist for high-resolution and high-transmittance semiconductors

A technology of positive photoresist and high light transmittance, applied in optics, optomechanical equipment, instruments, etc., can solve the problems of 3D printing photoresist and lack of production capacity of 193nm photoresist, etc. Achieve the effect of low production cost, small safety risk factor and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

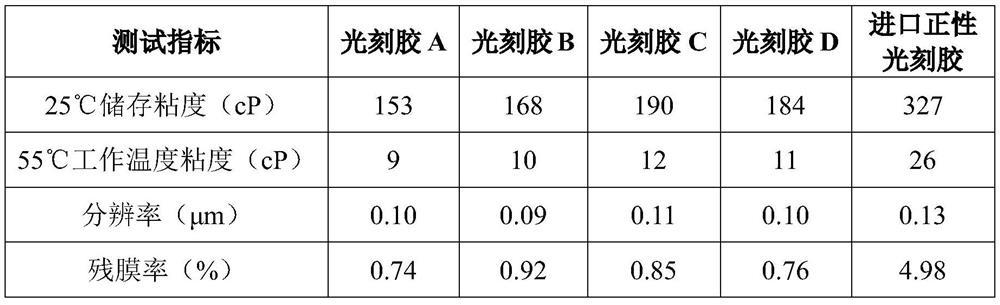

Examples

Embodiment 1

[0042] Preparation of 3D printing positive photoresist for high-resolution and high-transmittance semiconductors, the steps are as follows:

[0043] a. Add 0.1 part of Ce(NO 3 ) 3 Add 30 parts of tetraisopropyl titanate to 1000 parts of pure water and stir for 10 minutes, then add 20 parts of magnesium chloride and 1 part of lithium chloride, raise the temperature to 60°C and keep it warm for 10 minutes, then add 1000 parts of methyl methacrylate And fully stir evenly, then raise the temperature to 120°C and keep it warm for 30 minutes; then stop the reaction and cool down the material, wait for the reaction solution to stand until it is clearly separated, then discard the lower aqueous phase, keep the upper organic phase, and add to the organic phase 1000 parts of saturated saline and fully stirred, then left to stand until obvious separation, then discarded the lower aqueous phase, and retained the upper organic phase, that is, magnesium lithium titanate modified methyl met...

Embodiment 2

[0047] Preparation of 3D printing positive photoresist for high-resolution and high-transmittance semiconductors, the steps are as follows:

[0048] a. Add 0.2 parts of Ce 2 (SO 4 ) 3 , 0.3 parts Dy(NO 3 ) 3 , 40 parts of tetrabutyl orthotitanate, 20 parts of trihydroxyacyl isopropyl titanate were added to 1000 parts of pure water and stirred for 30 minutes, then 30 parts of magnesium sulfate, 20 parts of magnesium nitrate, 2.5 parts of lithium sulfate, 2.5 parts of Lithium nitrate, and heat up to 80°C and keep it warm for 30 minutes; then add 2000 parts of ethyl methacrylate and 1000 parts of butyl methacrylate and stir well, then heat up to 150°C and keep it warm for 60 minutes; then stop the reaction and cool down Discharging, wait for the reaction liquid to stand until it is clearly separated, then discard the lower aqueous phase, keep the upper organic phase, add 1000 parts of saturated saline to the organic phase and stir well, then let it stand until it is clearly s...

Embodiment 3

[0052] Preparation of 3D printing positive photoresist for high-resolution and high-transmittance semiconductors, the steps are as follows:

[0053] a. Add 0.1 part of CeCl 3 , 0.1 Dy 2 (SO 4 ) 3 , 0.1 parts of DyCl 3 , 10 parts of isopropyl tristearyl titanate, 20 parts of dihydroxyacyl ethylene diethylene titanate, and 10 parts of tetraisopropyl titanate were added to 1000 parts of pure water and stirred for 15 minutes, then 10 parts of magnesium chloride were added , 10 parts of magnesium sulfate, 10 parts of magnesium nitrate, 0.5 parts of lithium nitrate, 1.5 parts of lithium hydroxide, 0.5 parts of lithium carbonate, and the temperature was raised to 65 ° C and kept for 15 minutes, and then added 500 parts of glycidyl methacrylate, 500 parts 2-Ethylhexyl methacrylate, 500 parts of methoxypolyethylene glycol (350) monomethacrylate and stir well, then raise the temperature to 130°C and keep it warm for 40 minutes, then stop the reaction and cool down to discharge , wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com