Totally-inorganic LED packaging method and packaging structure

A technology for LED packaging and LED chips, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as increasing the risk of device failure, product failure, and decline in UV resistance, improving UV aging resistance, and simplifying the production process. , the effect of reducing the risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

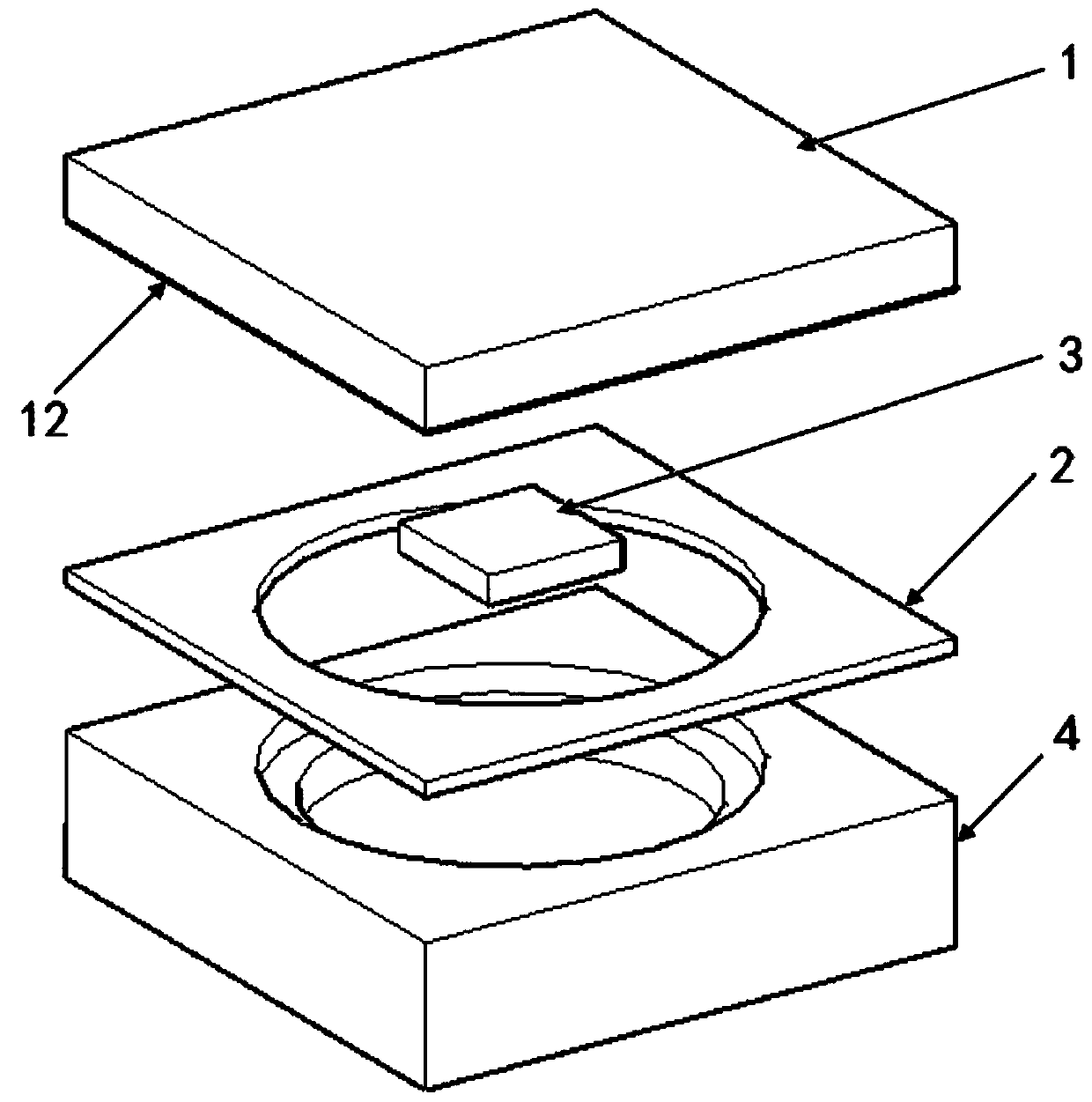

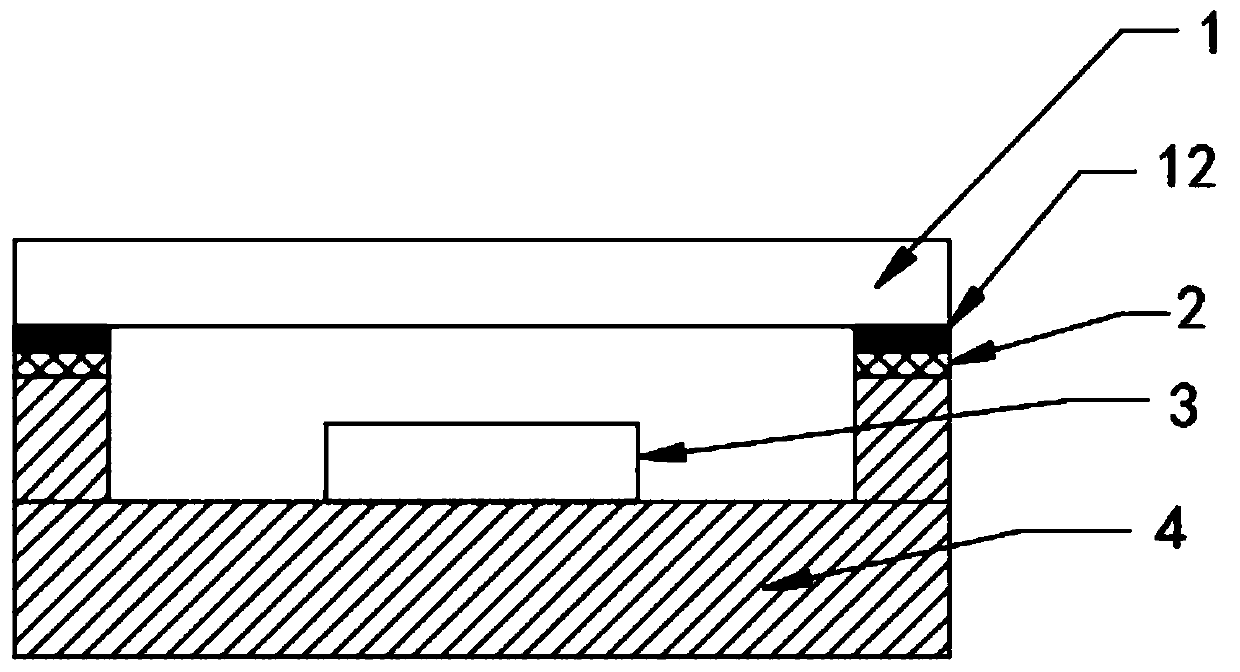

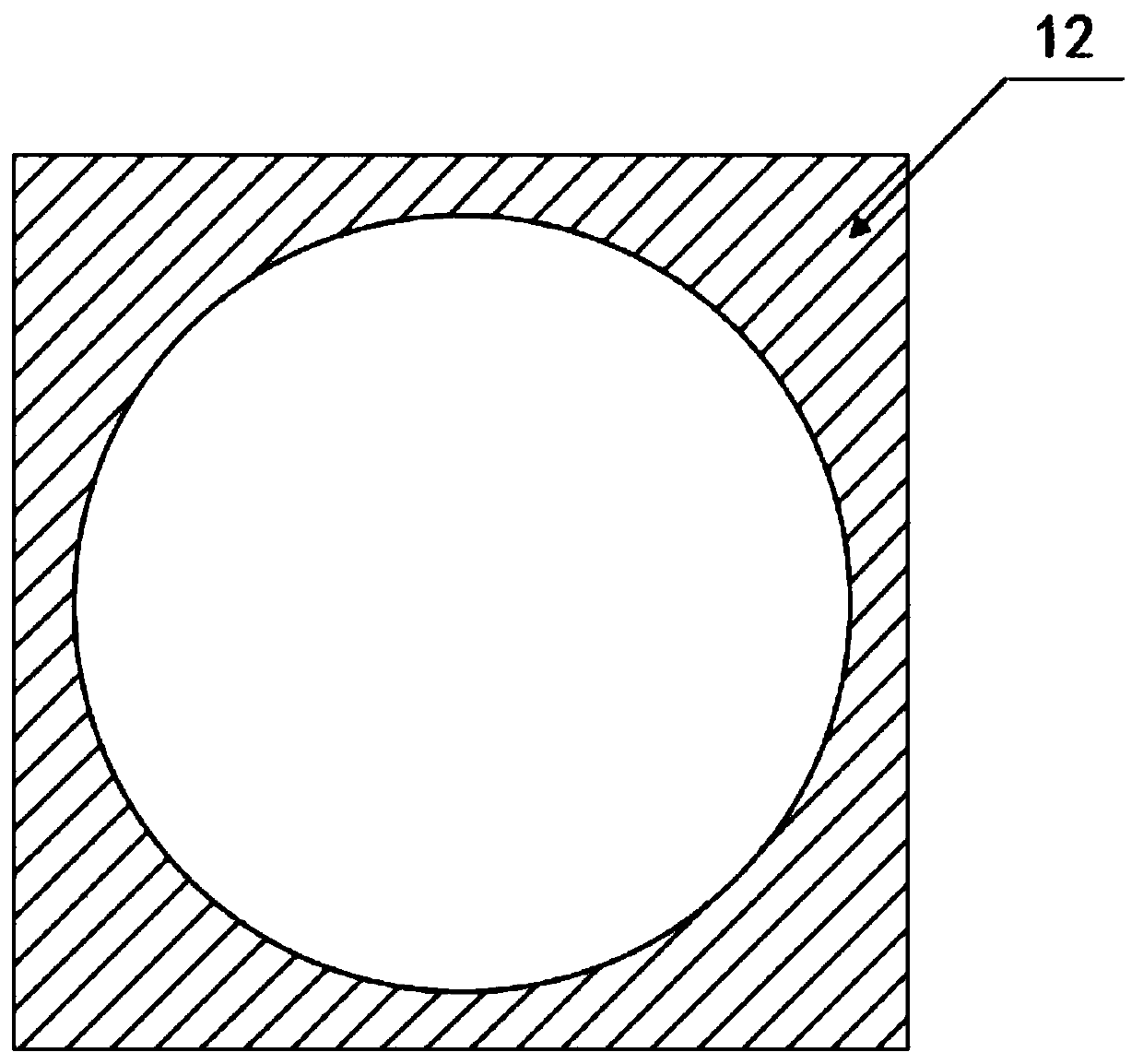

[0028] Such as Figure 1-Figure 3 As shown, the embodiment of the present invention provides an all-inorganic LED packaging structure, including a quartz light window 1 with a metallized frame, silver-copper nano paste 2, an LED chip 3 and a metal dam bracket 4, and the LED chip 3 is located on the metal dam In the center of the support 4, the metallized frame quartz light window 1 is located on the metal dam support 4, and the metal dam support 4 passes through the silver-copper nano paste 2 and the metallized frame quartz light window Phase 1 welding: the upper surface of the metal dam support 4 is a plane as the welding surface with the metallized frame quartz light window, and the silver-copper nano-paste 2 is provided on the welding surface of the metal dam support The metallized frame 21 on the bottom surface of the metallized frame quartz light window 1 matches the pattern of the welded surface of the metal dam support 4 .

[0029] The packaging method of the above-men...

Embodiment 2

[0042] Such as Figure 1-Figure 3 As shown, the embodiment of the present invention provides an all-inorganic LED packaging structure whose structural features are the same as those in Embodiment 1. The difference is that the preparation method is different:

[0043] The packaging method of the all-inorganic LED packaging structure provided by the embodiment of the present invention includes LED chip solidification, plasma cleaning, spot coating of silver-copper nano-paste, preparation of metallized frame quartz light window, low-temperature sintering and curing and other process steps (compared with the embodiment 1 is in the step 3 part), as follows:

[0044] Step 1. LED chip solidification: In LED chip solidification, use a solid crystal machine to place the LED chip inside the cleaned metal dam bracket. The solid crystal material can use silver glue, metal solder paste and gold-tin co- For crystal packaging, the heat resistance temperature is required to be not less than...

Embodiment 3

[0056] Such as Figure 1-Figure 3 As shown, the embodiment of the present invention provides an all-inorganic LED packaging structure. The structural features are the same as those in Embodiment 1, except that the preparation method is different:

[0057] The packaging method of the all-inorganic LED packaging structure provided by the embodiment of the present invention includes LED chip solidification, plasma cleaning, spot coating of silver-copper nano-paste, preparation of metallized frame quartz light window, low-temperature sintering and curing and other process steps (compared with the embodiment 1 is in the step 3 part), as follows:

[0058] Step 1. LED chip solidification: In LED chip solidification, use a solid crystal machine to place the LED chip inside the cleaned metal dam bracket. The solid crystal material can use silver glue, metal solder paste and gold-tin co- For crystal packaging, the heat resistance temperature is required to be not less than 200°C;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com