Wood carbon fiber/metal oxide composite negative electrode material and its preparation method and application

A technology of negative electrode material and wood charcoal, which is applied in the manufacture of electrolyte batteries, battery electrodes, and final product manufacture, etc. problem, to achieve the effect of rapid radial ion diffusion, simple and easy process, and unique anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A kind of preparation method of wood charcoal fiber / metal oxide composite negative electrode material of the present invention, comprises the following steps:

[0039] (1) Disperse the wood charcoal fiber in the aqueous solution with surface modifier, then add the metal salt, stir and mix evenly, put it in the reaction vessel, carry out the hydrothermal reaction at 120℃~160℃, on the surface of the wood charcoal fiber After in-situ growth of the metal oxide precursor, a precipitate is obtained;

[0040] (2) After the precipitate obtained in step (1) is filtered and dried, the temperature is raised to 400° C. to 600° C. for sintering under a protective gas atmosphere to obtain a wood carbon fiber / metal oxide composite negative electrode material.

[0041] The preparation method of the invention can improve the defect of low tap density after pyrolysis and carbonization in the biomass raw material, and significantly improve the volume energy density of the negative electro...

Embodiment 1

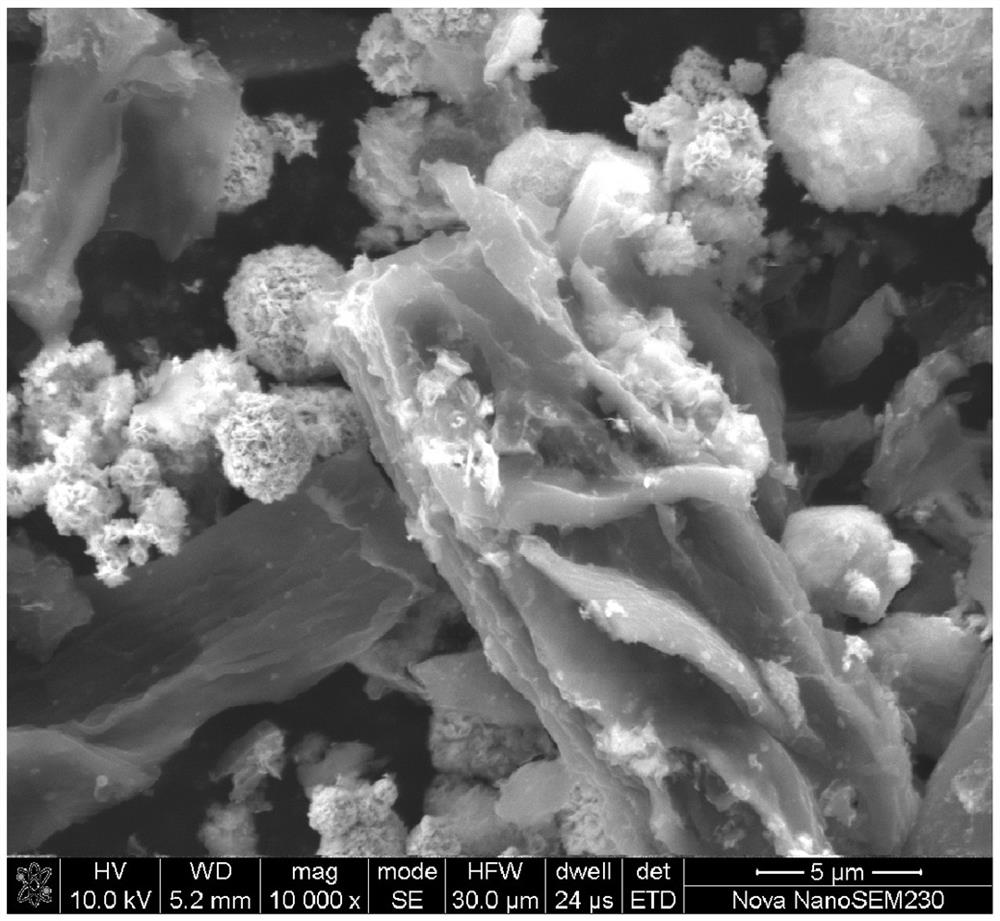

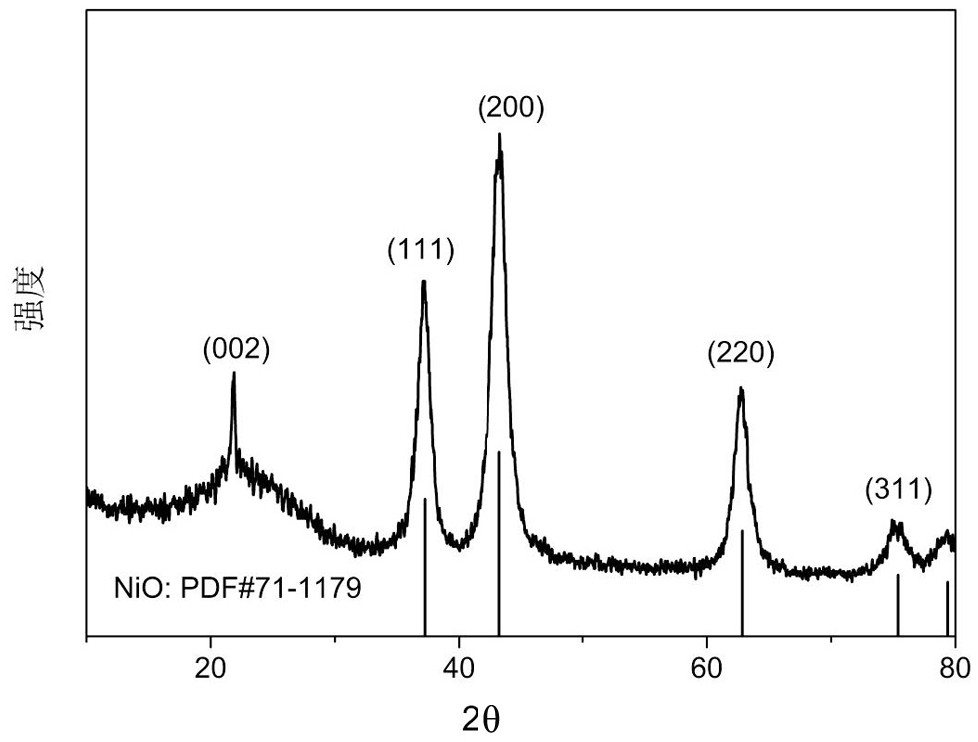

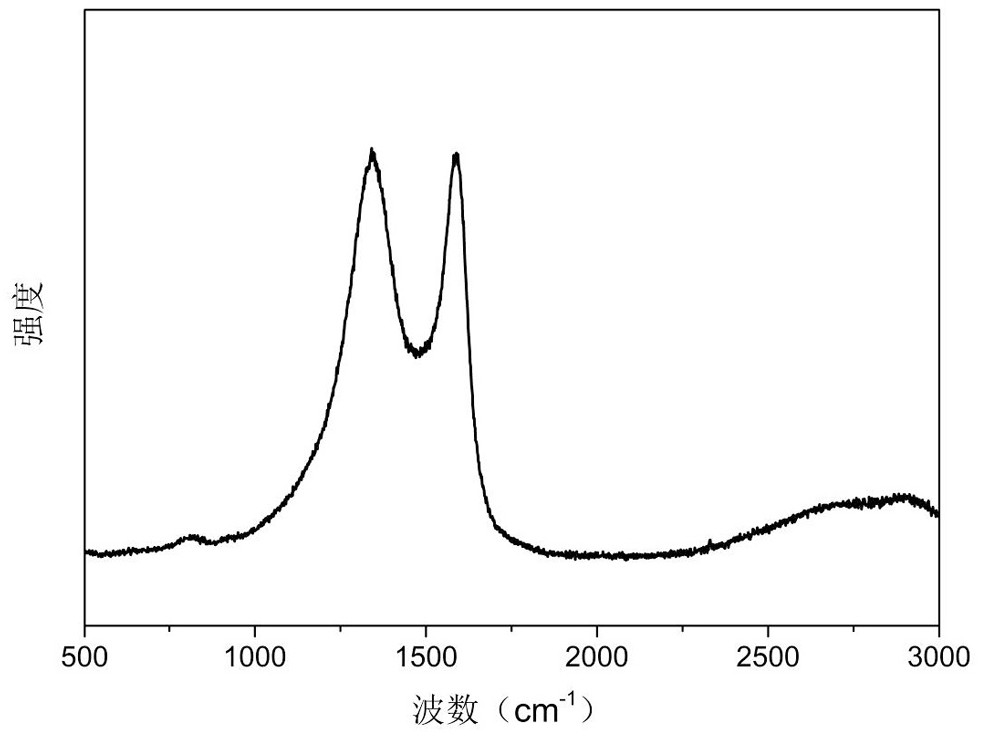

[0043]A wood-charcoal fiber / metal oxide composite anode material of this embodiment, the wood-charcoal fiber has a diameter of 1 μm to 10 μm, and NiO nanoparticles are uniformly distributed on the surface of the wood-charcoal fiber to form a three-dimensional composite structure. When the charge and discharge current is 50mA / g, the first discharge specific capacity reaches 978.7 mAh / g, and the charge specific capacity is 633.2 mAh / g.

[0044] A preparation method of the wood charcoal fiber / metal oxide composite negative electrode material of the present embodiment, comprising the following steps:

[0045] (1) Disperse 1 g of wood charcoal fiber in 60 mL of aqueous solution with 0.1 g of cetyltrimethylammonium bromide (CTAB), then add 2 g of nickel nitrate, and mix evenly with ultrasonic stirring to obtain a mixed solution. Then the mixed solution was put into a hydrothermal reaction kettle, and the hydrothermal reaction was carried out at 120 °C for 12 h, and the NiO precursor...

Embodiment 2

[0055] A preparation method of the wood charcoal fiber / metal oxide composite negative electrode material of the present embodiment, comprising the following steps:

[0056] (1) Disperse 1 g of wood charcoal fiber in 60 mL of aqueous solution with 0.1 g of CTAB, then add 1 g of nickel nitrate, and mix evenly with ultrasonic stirring to obtain a mixed solution, and then put the mixed solution into a hydrothermal reaction kettle, The hydrothermal reaction was carried out at 120 °C for 6 h, and the NiO precursor was grown in situ on the surface of woody carbon fibers to obtain precipitates.

[0057] (2) After the precipitate obtained in step (1) was filtered, washed, and dried, it was put into a tube furnace with argon for sintering, and the temperature was raised to 400 °C at 10 °C / min and kept for 3 h, then cooled to room temperature to obtain Wood carbon fiber / metal oxide composite anode material.

[0058] In this embodiment, the wood charcoal fiber is wood charcoal fiber. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com