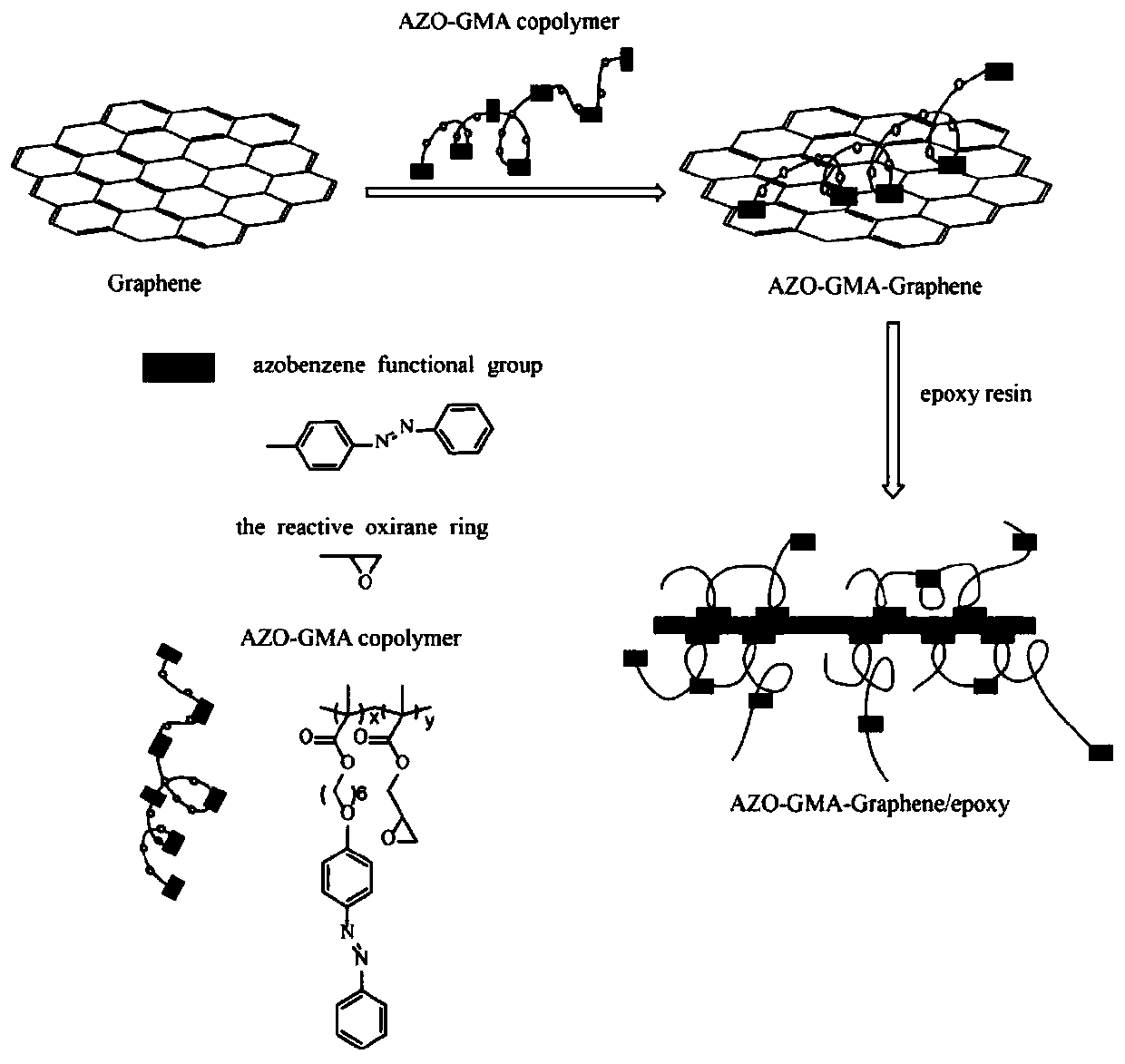

Graphene/azobenzene polymer composite anti-corrosive paint additive and preparation method thereof

An anti-corrosion coating, graphene technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings and other directions, to expand the application field, improve dispersion, improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

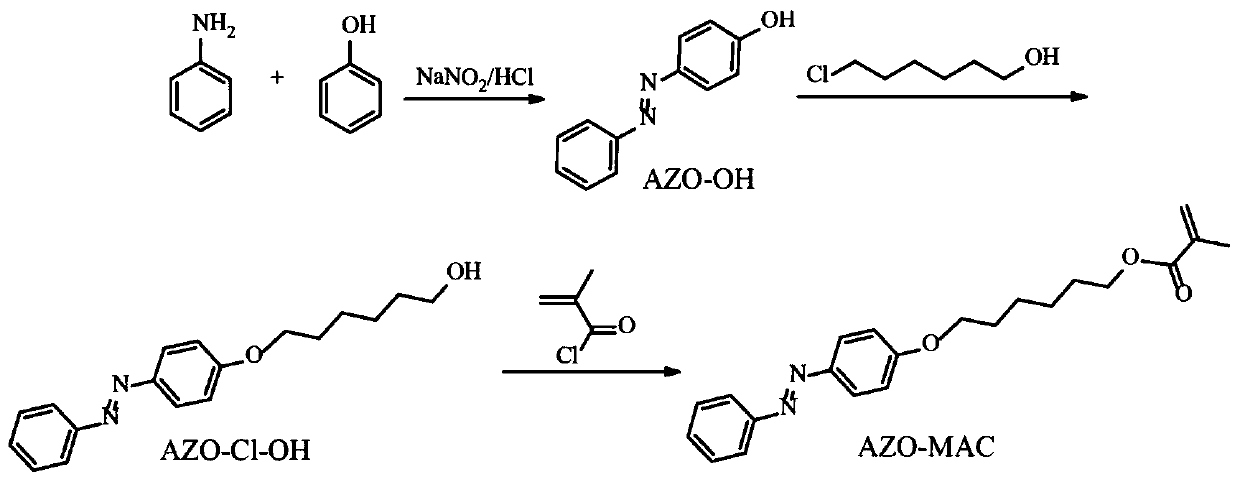

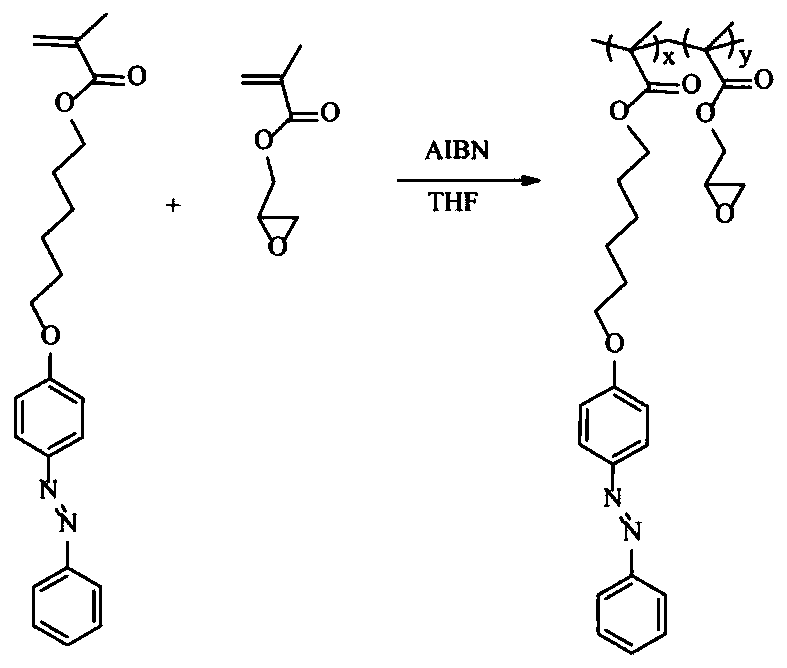

[0037] 1. Synthesis of AZO-MAC

[0038] figure 2 It is a schematic diagram of the synthetic route of AZO-MAC. Firstly, diazotize aniline and phenol in an ice bath to obtain hydroxyazobenzene AZO-OH; secondly, carry out chain extension reaction of hydroxyazobenzene with 6-chloro-1-hexanol to obtain chain-extended The hydroxyazobenzene AZO-Cl-OH; finally, the chain-extended hydroxyazobenzene AZO-Cl-OH is reacted with methacryloyl chloride to obtain the azobenzene AZO-MAC containing double bonds.

[0039] Concrete synthesis process is as follows:

[0040] (1) Synthesis steps of AZO-OH

[0041] In a 100mL single-necked bottle, add concentrated hydrochloric acid (8mL) and deionized water (8mL), cool to 0°C, then add aniline (2.5g 0.027mol), add sodium nitrite (2g 0.029mol) in 10mL deionized water In the reaction system, keep the temperature at 0°C and continue to stir for 30 minutes, then dissolve phenol (2.5g 0.027mol) in 25mL of 10% sodium hydroxide solution, add it to the d...

Embodiment 2

[0051] 1. Synthesis of AZO-MAC

[0052] (1) Synthesis steps of AZO-OH

[0053] In a 250mL single-necked bottle, add concentrated hydrochloric acid (16mL) and deionized water (16mL), cool to 0°C, then add aniline (5g 0.054mol), add sodium nitrite (4g 0.058mol) in 20mL deionized water to react In the system, keep the temperature at 0°C, keep stirring for 30 minutes, then dissolve phenol (5g 0.054mol) in 50mL of 10% sodium hydroxide solution, add it into the diazonium salt system at a rate of two seconds per drop, and continue the reaction for 3h , Next, adjust the pH of the system to about 7, precipitation occurs, and the yellow-orange solid is filtered out and washed with deionized water several times, and finally, freeze-dried to obtain the desired product AZO-OH.

[0054] (2) Synthesis steps of AZO-Cl-OH

[0055] In a 150mL single-necked bottle, add hydroxyazobenzene AZO-OH (3.9644g 0.02mol), anhydrous potassium carbonate K 2 CO 3 (3.0406g 0.022mol), 6-chloro-1-hexanol (3...

Embodiment 3

[0063] 1. Synthesis of AZO-MAC

[0064] (1) Synthesis steps of AZO-OH

[0065] In a 100mL single-necked bottle, add concentrated hydrochloric acid (8mL) and deionized water (8mL), cool to 0°C, then add aniline (2.5g 0.027mol), add sodium nitrite (2g 0.029mol) in 10mL deionized water In the reaction system, keep the temperature at 0°C and continue to stir for 30 minutes, then dissolve phenol (2.5g 0.027mol) in 25mL of 10% sodium hydroxide solution, add it to the diazonium salt system at a rate of two seconds per drop, and continue After reacting for 6 hours, adjust the pH of the system to about 7. Precipitation occurs. The yellow-orange solid is filtered out and washed with deionized water several times. Finally, the desired product AZO-OH can be obtained by freeze-drying.

[0066] (2) Synthesis steps of AZO-Cl-OH

[0067] In a 150mL single-necked bottle, add hydroxyazobenzene AZO-OH (3.9644g 0.02mol), anhydrous potassium carbonate K 2 CO 3 (3.3170g 0.024mol), 6-chloro-1-he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com