A method for processing top-contact organic field-effect transistors by laser

A technology of laser processing and contact structure, which is applied in the manufacture of semiconductor devices, electrical solid-state devices, semiconductor/solid-state devices, etc. It can solve the problems of device resolution and performance degradation, device processing quality is difficult to guarantee, and graphene pattern resolution is low. , to achieve high production efficiency, realize large-scale manufacturing and large-scale industrialization, and achieve the effect of small contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

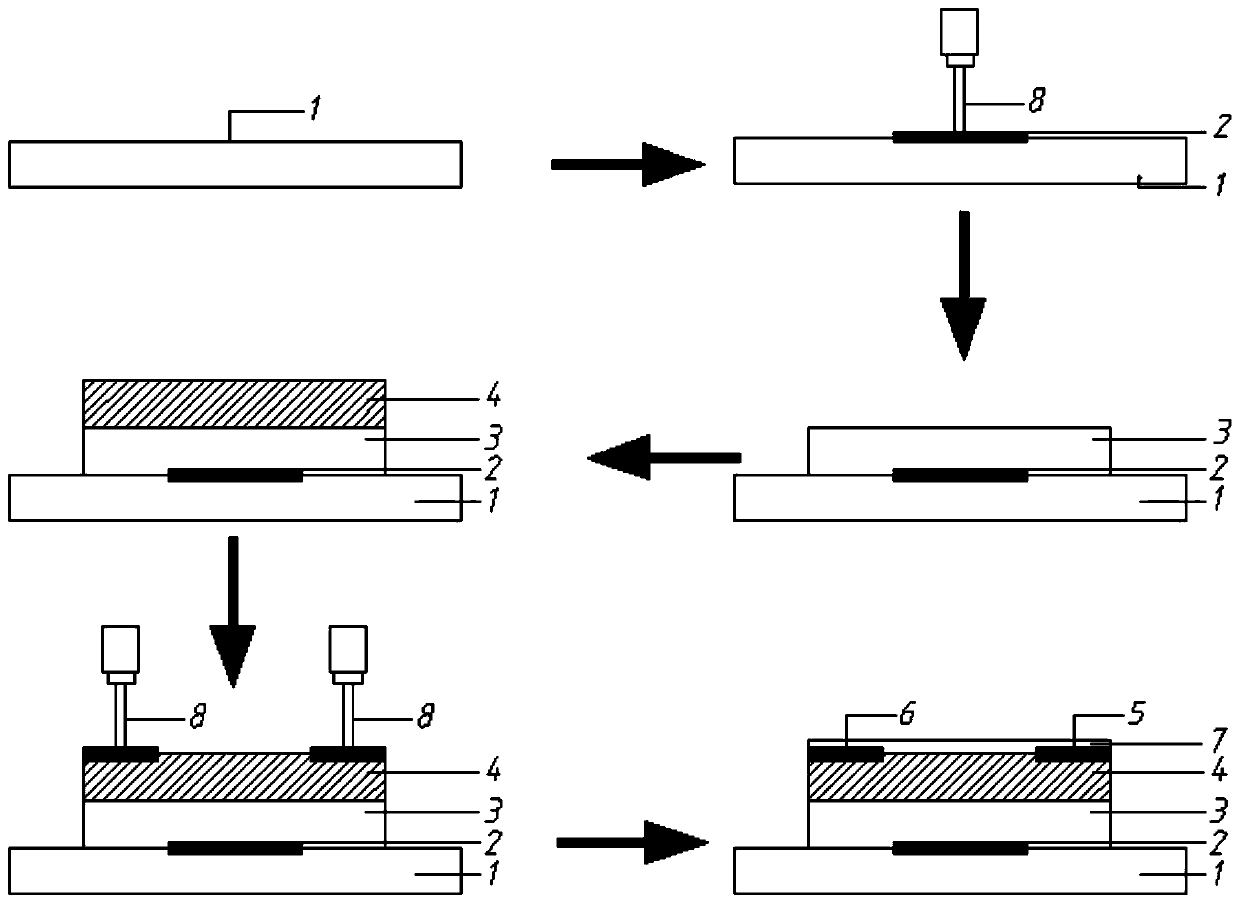

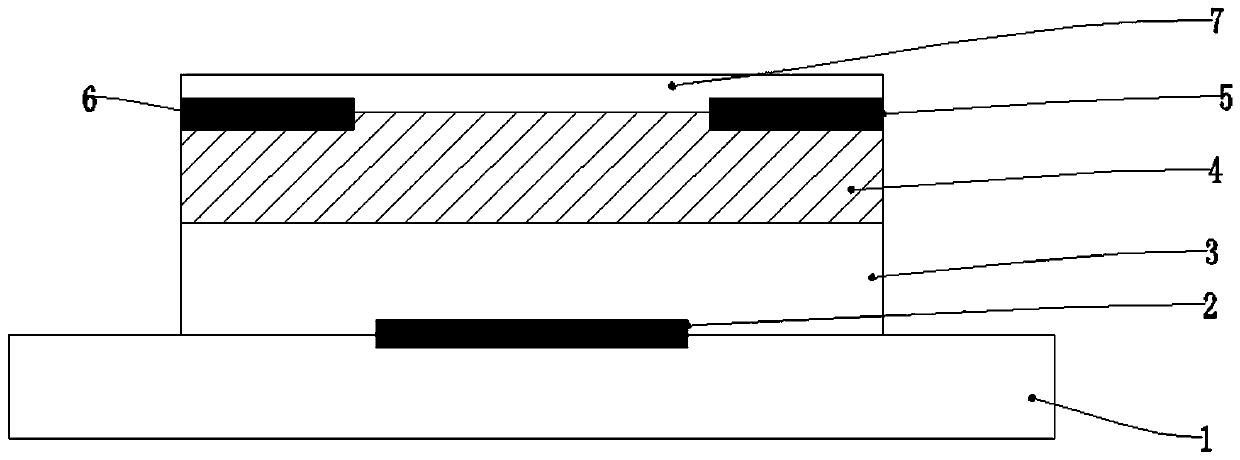

[0053] The method for processing an organic field-effect transistor with a top-contact structure by laser in this embodiment is used to prepare an organic field-effect transistor with a bottom-gate top-contact structure, such as figure 1 shown, including the following steps:

[0054] Step A, use cleaning powder to scrub the flexible substrate 1 with a thickness of 120 μm, then divide the flexible substrate 1 into 3 cm×2 cm, then ultrasonically clean it with acetone, ethanol and deionized water, and then dry it with nitrogen, And through surface plasma treatment, the surface of the flexible substrate 1 becomes hydrophilic;

[0055] Step B, the parameters of the laser processing system 8 are set as the processing parameters of the gate electrode 2 and the processing pattern is set as the pattern of the gate electrode 2, and then the laser processing system 8 performs laser processing on the area where the gate electrode 2 is set on the flexible substrate 1 , converting the surf...

Embodiment 2

[0095] The preparation scheme of the bottom gate top contact structure organic field effect transistor of the present embodiment is as follows:

[0096] Step 1, such as figure 1 As shown, a polyimide film with a thickness of 120 μm was selected as the flexible substrate 1, and the flexible substrate 1 was scrubbed with detergent powder, and then the flexible substrate 1 was divided into 3 cm × 2 cm, and then cleaned with acetone and ethanol respectively. Ultrasonic cleaning with deionized water, then drying with nitrogen, and surface plasma treatment, so that the surface of the flexible substrate 1 becomes hydrophilic;

[0097] Step 2, the parameters of the laser processing system 8 are set as the processing parameters of the grid electrode 2 and the processing pattern is set as the pattern of the grid electrode 2, the processing parameters of the grid electrode 2 are: the power duty cycle is 40% and the laser scanning speed is 100mm / s, the pattern size of the gate electrode ...

Embodiment 3

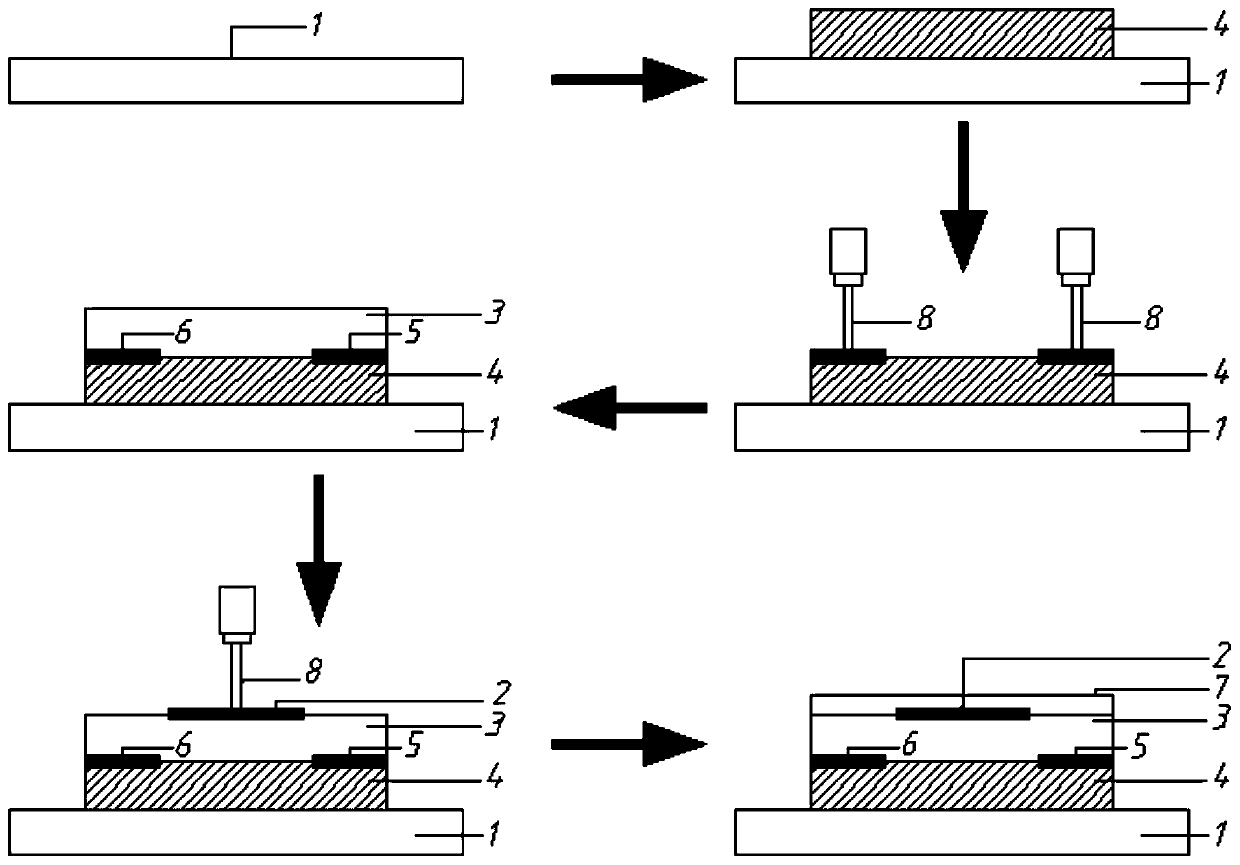

[0110] The preparation scheme of the top gate top contact structure organic field effect transistor of this embodiment is as follows:

[0111] Step 1, such as image 3 As shown, a polyimide film with a thickness of 120 μm was selected as the flexible substrate 1, and the flexible substrate 1 was scrubbed with detergent powder, and then the flexible substrate 1 was divided into 3 cm × 2 cm, and then cleaned with acetone and ethanol respectively. Ultrasonic cleaning with deionized water, then drying with nitrogen, and surface plasma treatment, so that the surface of the flexible substrate 1 becomes hydrophilic;

[0112] Step 2, mixing poly-3-hexylthiophene and absolute ethanol at a volume ratio of 5:1, and stirring in a magnetic stirrer for 10 minutes to obtain an organic semiconductor solution;

[0113] Step 3, put the flexible substrate 1 on the workbench of the glue homogenizer, take 3 drops of the organic semiconductor solution in step 2 with a pipette and drop it on the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com