Bismuth oxybromide ternary heterostructure photocatalyst as well as preparation method and application thereof

A heterogeneous structure, bismuth oxybromide technology, applied in the field of photocatalytic materials, can solve the problems of easy recombination of photogenerated electrons and holes, weak visible light absorption response, and limited photocatalytic ability, so as to achieve stable chemical properties and improve photon utilization rate, improve the effect of photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 pure BiOBr photocatalyst

[0024] (1) Preparation method

[0025] Measure 1.94 g of bismuth nitrate pentahydrate, dissolve it in 20 ml of ethylene glycol with heating and stirring, and cool to room temperature. Measure 0.595 g of potassium bromide and dissolve it in 20 ml of ethylene glycol with stirring. Ethylene glycol dissolved with potassium bromide was added dropwise into the bismuth nitrate solution, stirred for 1 hour, and then kept in a high-pressure hydrothermal kettle at 120°C for 12 hours. After the high-pressure hydrothermal kettle was cooled to room temperature, it was washed and dried by centrifugation with deionized water and ethanol to obtain a pure BiOBr photocatalyst.

[0026] (2) Detection

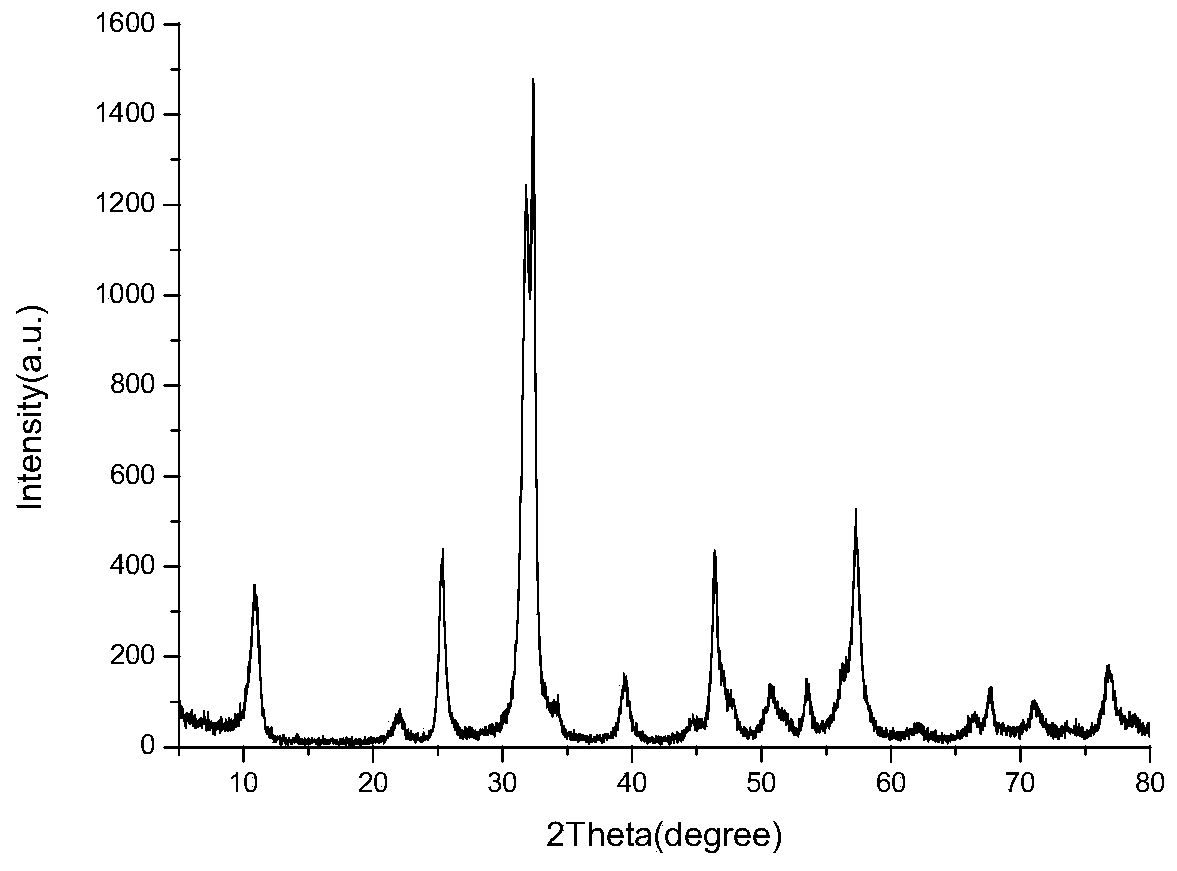

[0027] figure 1 XRD detection for pure BiOBr photocatalyst samples. Depend on figure 1 It can be seen that there are no other impurity peaks, indicating that there are no other impurity phases in the product, and what is obtained is a single pha...

Embodiment 2 3

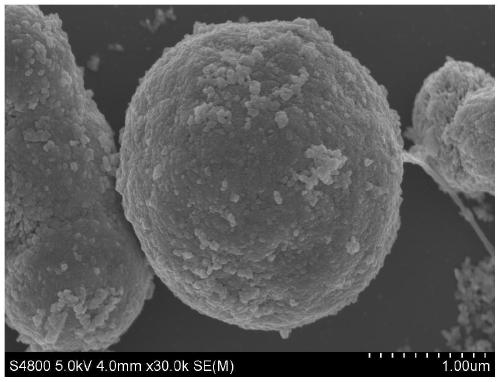

[0028] Example 2 Ternary heterostructure BiOBr photocatalyst

[0029] 1) Stir and dissolve 0.595g potassium bromide in 20mL ethylene glycol, then add 0.0184g g-C3N4 and stir for 30min to obtain solution A.

[0030] 2) Heat and dissolve 1.94g of bismuth nitrate pentahydrate in 20mL of ethylene glycol and cool to room temperature, then add 0.068g of silver nitrate and stir to dissolve to obtain solution B.

[0031] 3) Add solution A dropwise to solution B and stir for 1-2 hours, then place in a high-pressure hydrothermal kettle, place the high-pressure hydrothermal kettle in an oven at 120°C for 12 hours, and wash with deionized water and ethanol centrifugally after the reaction , and dried to obtain a ternary heterostructure BiOBr.

[0032] (2) Detection

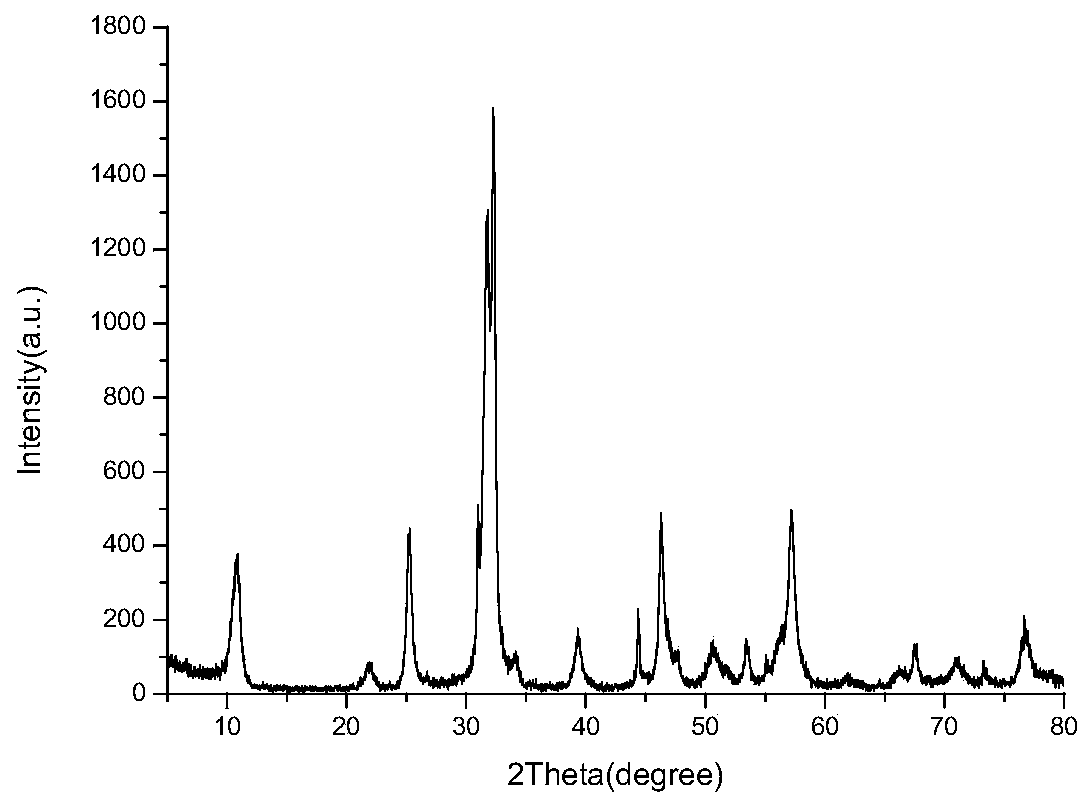

[0033] image 3 It is the XRD detection of the ternary heterostructure BiOBr catalyst sample. Depend on image 3 It can be seen that the sample has good crystallinity. As shown in the figure, the sample has two diffracti...

Embodiment 3 3

[0037] Application of embodiment 3 ternary heterostructure BiOBr photocatalyst

[0038] The ternary heterostructure BiOBr photocatalysts prepared in Examples 1 and 2 were tested for photocatalyst material properties. The method is as follows: put 0.01 g of pure BiOBr and ternary heterostructure BiOBr into 100 ml glass beakers, add 50 ml of 2 g / ml rhodamine b solution, and stir in a dark room for 1 h. Use a 300W xenon lamp as the light source, adjust the photocurrent to 20mA, place the glass beaker directly under the xenon lamp light source, turn on the xenon lamp immediately after taking the first sample, and take the second sample after 10 minutes, and take a sample every 10 minutes , each sample was subjected to a visible light absorption test, and the areas of the absorption peaks were compared. The result is as Figure 7 As shown, after 1 h of light irradiation, the pure BiOBr catalyst degrades rhodamine b by 30%, while the ternary heterostructure BiOBr degrades rhodamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com