A method for separating and purifying sulodexide bulk drug from heparin by-products

A technology for heparin by-products and raw materials, applied in the field of medicine, can solve the problems of lack of ability to remove impurities such as pigments, proteins, difficulties in industrial production, and poor product appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

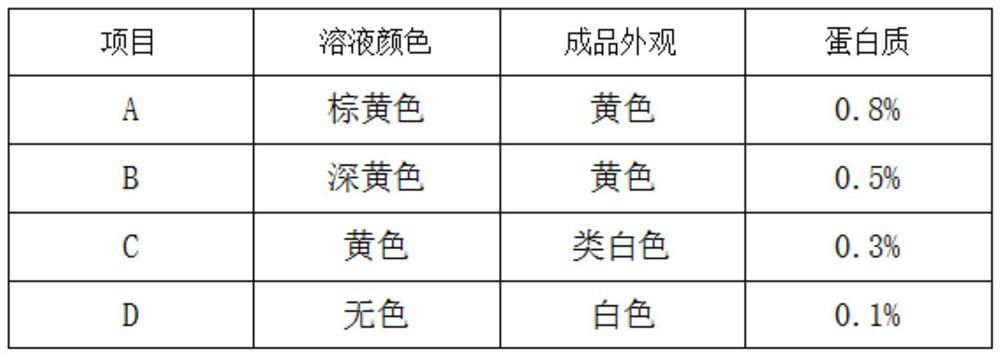

Image

Examples

Embodiment 1

[0047] S1. Pretreatment of heparin by-products: Dissolve heparin by-products heparin 5%, heparan sulfate 45% and dermatan sulfate 47% with a titer of 29 usp u / mg into a solution with a mass fraction of 5%. Dissolve 2% sodium chloride, then add 95% ethanol until the ethanol concentration is 30%, keep it warm for 4 hours, pour out the supernatant, and remove the lower precipitate;

[0048] S2. Separation of heparin: continue to add 95% ethanol to the supernatant obtained in S1 until the ethanol concentration is 50%, keep it warm for 4 hours, precipitate, dehydrate, dry and dry to obtain the crude product after removing heparin;

[0049] S3. Pretreatment of crude heparin: add water to dissolve the crude product in step S1 into a solution with a mass fraction of 10%, raise the temperature to 25° C., dissolve the feed solution with 2% sodium chloride, and then adjust the pH to 11 with sodium hydroxide solution. Then add 2% anhydrous sodium carbonate-sodium bicarbonate buffer soluti...

Embodiment 2

[0053] S1. Pretreatment of heparin by-products: Dissolve heparin by-products heparin 5%, heparan sulfate 45% and dermatan sulfate 47% with a titer of 29 usp u / mg into a solution with a mass fraction of 10%, and heat up to 38°C. Dissolve 2% sodium chloride, then add 95% ethanol until the ethanol concentration is 35%, keep warm for 4 hours, pour out the supernatant, and remove the lower precipitate;

[0054] S2. Separation of heparin: continue to add 95% ethanol to the supernatant obtained in S1 until the ethanol concentration is 50%, keep it warm for 4 hours, precipitate, dehydrate, dry and dry to obtain the crude product after removing heparin;

[0055] S3. Pretreatment of crude heparin: add water to dissolve the crude product in step S1 into a solution with a mass fraction of 10%, raise the temperature to 27°C, dissolve the feed solution with 2% sodium chloride, and then adjust the pH to 11 with sodium hydroxide solution. Then add 2% anhydrous sodium carbonate-sodium bicarbon...

Embodiment 3

[0059] S1. Pretreatment of heparin by-products: Dissolve heparin by-products heparin 5%, heparan sulfate 45% and dermatan sulfate 47% with a titer of 29usp u / mg into a solution with a mass fraction of 15%, and heat up to 40°C. Dissolve 2% sodium chloride, then add 95% ethanol until the ethanol concentration is 30%, keep it warm for 4 hours, pour out the supernatant, and remove the lower precipitate;

[0060] S2. Separation of heparin: continue to add 95% ethanol to the supernatant obtained in S1 until the ethanol concentration is 46%, keep it warm for 4 hours, precipitate, dehydrate, dry and dry to obtain the crude product after removing heparin;

[0061] S3. Pretreatment of crude heparin: dissolve the crude product in step S1 with water to a solution with a mass fraction of 12%, raise the temperature to 30° C., dissolve the feed solution with 2% sodium chloride, and then adjust the pH to 11 with sodium hydroxide solution. Then add 2% anhydrous sodium carbonate-sodium bicarbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com