An integrated method for forming and connecting aluminum-magnesium composite components

A technology of composite components and aluminum alloy melt, which is applied in the forging, forming and connection integration of aluminum alloy and magnesium alloy bimetallic composite components, and in the field of bimetal component forming, which can solve the problem of poor oxidation and corrosion resistance on the surface of magnesium alloys and difficulty in realizing aluminum alloys. Problems such as the connection of magnesium composite components and the difficulty of obtaining a flat interface in solid state composite forging achieve the effects of low deformation resistance, compact structure, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

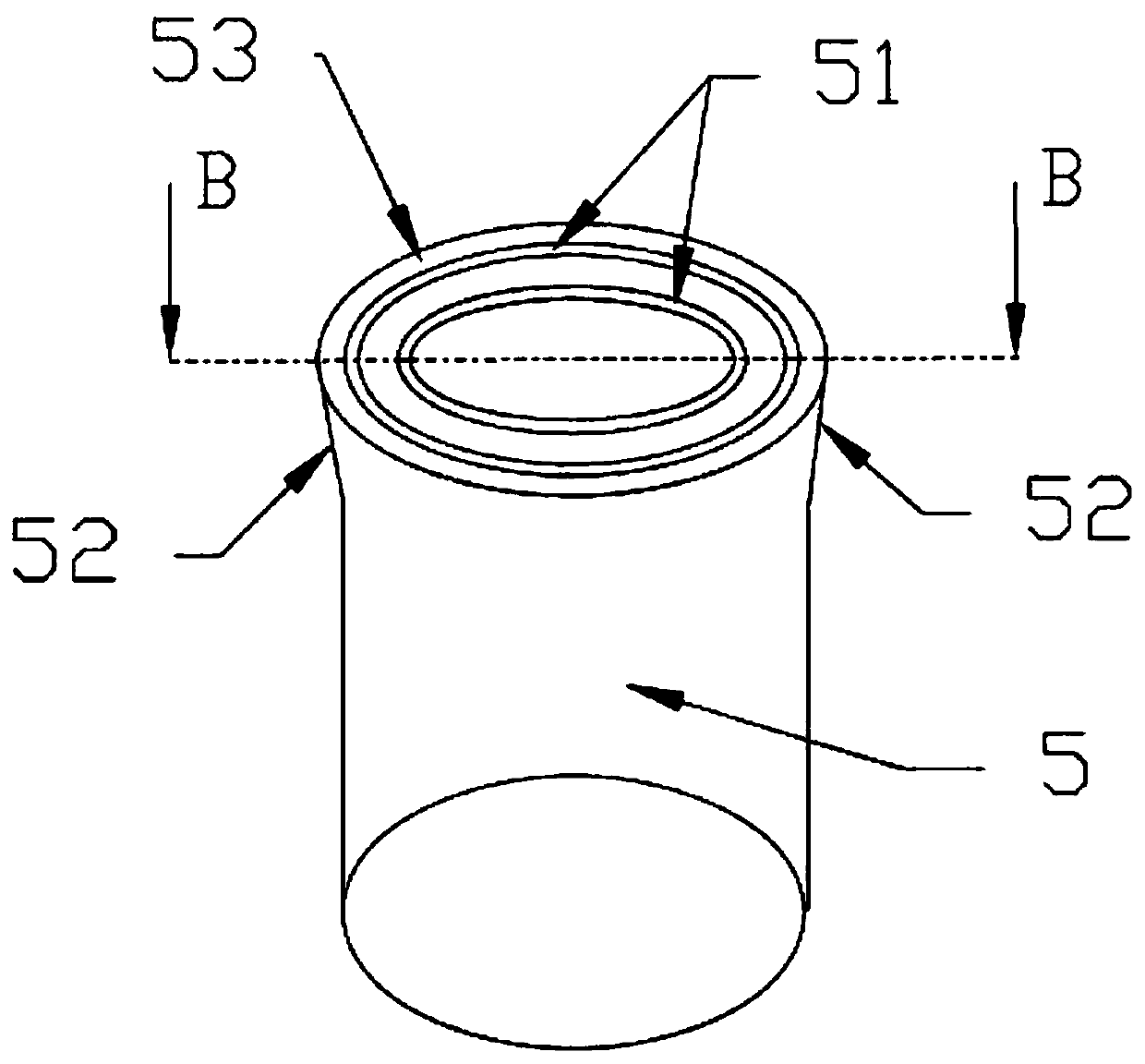

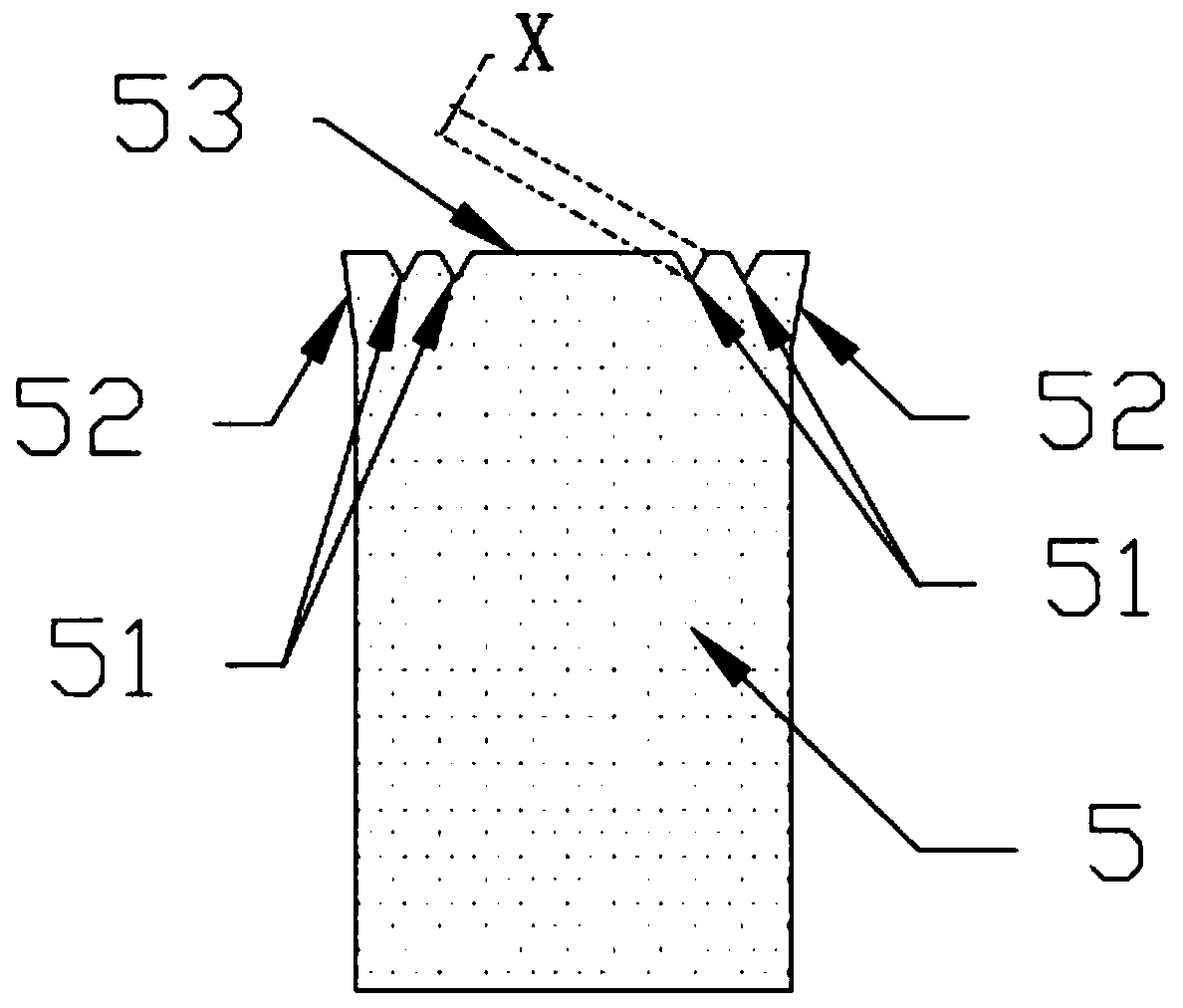

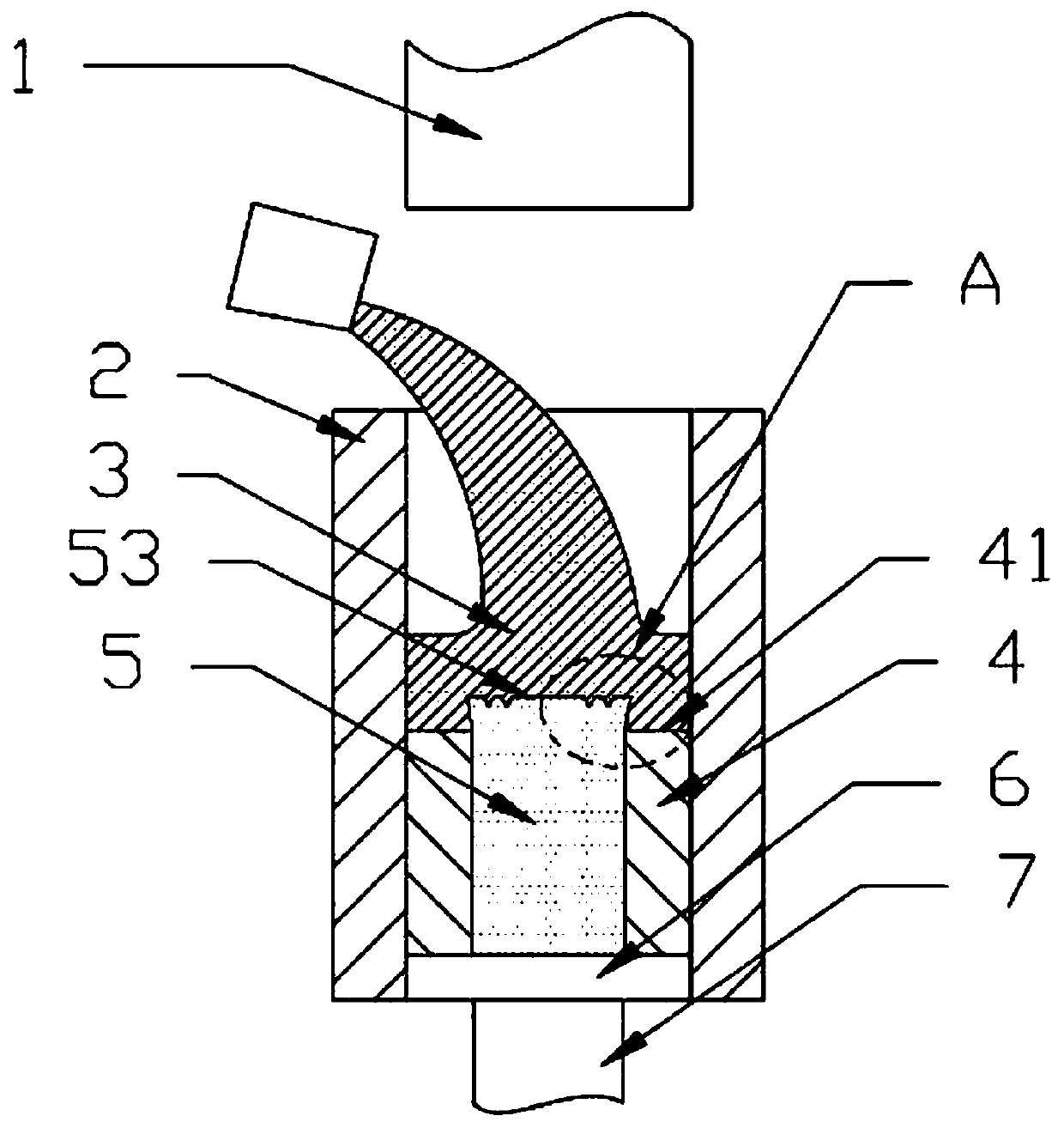

[0057] 1. Process the AZ31 magnesium alloy material into a cylindrical blank of φ18×h25 mm, cut the contact side wall 52 to form a negative taper with a length of 5 mm and an angle of 1°, and simultaneously cut and process the side length on the upper surface of the magnesium alloy material 0.4mm, diameters are respectively φ14, φ16 annular groove 51, the cross-sectional shape of the annular groove 51 is triangular;

[0058] 2. Heat the mold cavity 2 to 200°C and keep it warm;

[0059] 3. Heat the AA6061 aluminum alloy material to 720°C with an infrared heating device or an induction heating device, then keep it warm at 720°C and let it stand for 10 minutes to fully melt, add refining agent and sprinkle it on the liquid surface, stir it fully and put it back into the furnace to keep it warm 720°C and stand for 5 minutes to make it fully refined; from the fully refined aluminum alloy liquid, metal impurities, oxides and other oxide inclusions, etc. are separated by conventional...

specific Embodiment approach 2

[0063] 1. Process the LA141 magnesium-lithium alloy material into a cylindrical blank of φ18×h25 mm, cut the contact side wall 52 to form a negative taper with a length of 5 mm and an angle of 10°, and simultaneously cut and process the edge on the upper surface of the magnesium alloy material An annular groove 51 with a length of 0.4 mm and a diameter of φ14 and φ16 respectively, the cross-sectional shape of the annular groove 51 is triangular;

[0064] 2. Heat the mold cavity 2 to 200°C and keep it warm;

[0065]3. Heat the AA3003 antirust aluminum alloy material to 750°C with an infrared heating device or an induction heating device, then keep it warm at 750°C and let it stand for 10 minutes to fully melt, add refining agent and sprinkle it on the liquid surface, stir it fully and put it back into the furnace Keep warm at 750°C and stand for 10 minutes to make it fully refined; from the fully refined aluminum alloy liquid, metal impurities, oxides and other oxide inclusions...

specific Embodiment approach 3

[0069] 1. Machining the MA18 magnesium-lithium alloy material into a cylindrical blank of φ18×h25 mm, cutting the contact side wall 52 to form a negative taper with a length of 5 mm and an angle of 5°, and cutting and machining the edge on the upper surface of the magnesium alloy material An annular groove 51 with a length of 0.4 mm and a diameter of φ14 and φ16 respectively, the cross-sectional shape of the annular groove 51 is triangular;

[0070] 2. Heat the mold cavity 2 to 200°C and keep it warm;

[0071] 3. Heat the AA7075 superhard aluminum alloy material to 700°C with an infrared heating device or an induction heating device, then keep it warm at 700°C and let it stand for 10 minutes to fully melt, add refining agent and sprinkle it on the liquid surface, stir it fully and put it back into the furnace Keep warm at 700°C and let it stand for 10 minutes to make it fully refined; from the fully refined aluminum alloy liquid, metal impurities, oxides and other oxide inclus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com