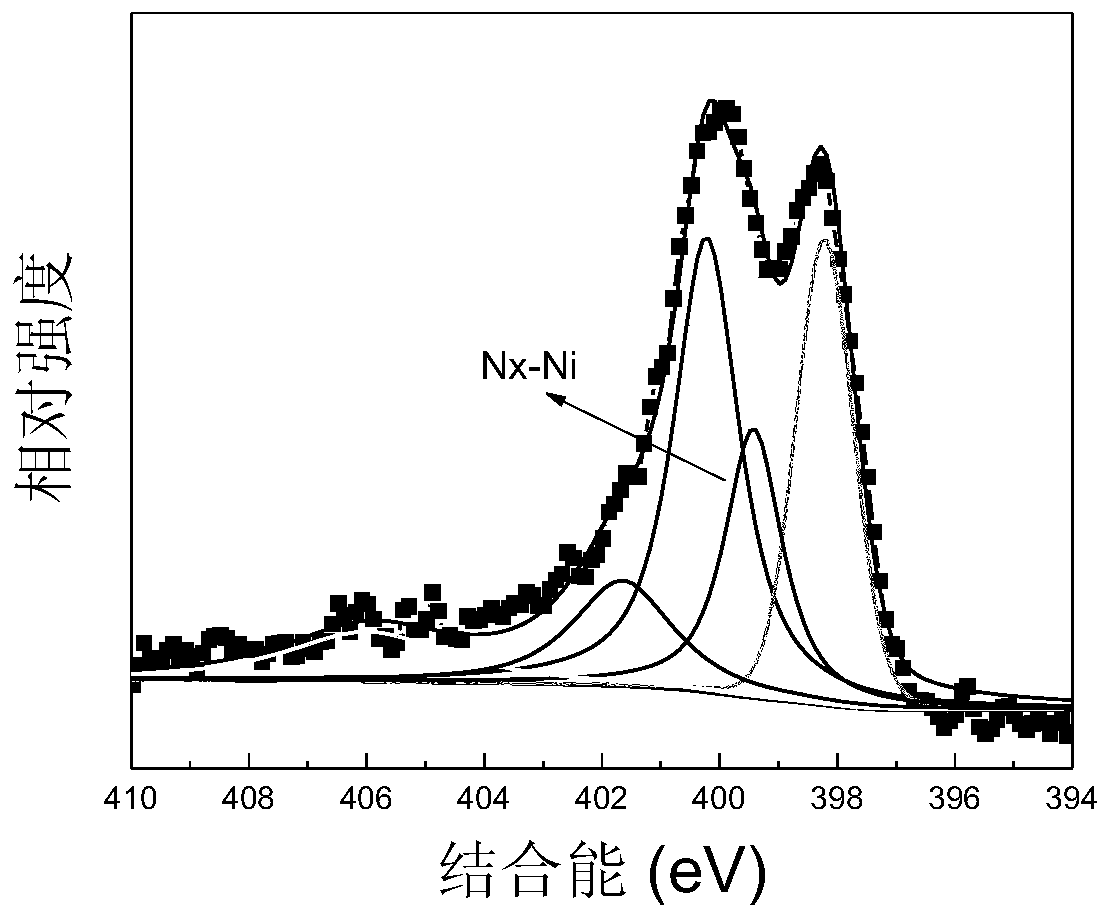

A nickel-nitrogen codoped carbon electrocatalyst and a preparing method and application thereof

An electrocatalyst, co-doping technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., to achieve the effect of improving selectivity, easy industrial production, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

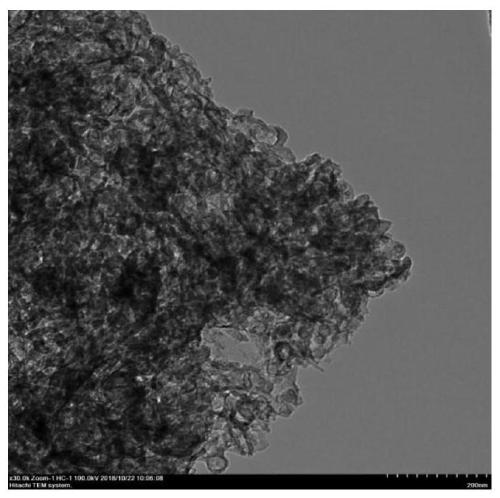

[0031] The preparation steps of nickel-nitrogen co-doped porous carbon nanosheets are:

[0032] Step 1. Add 5.5mol sodium benzoate (C 7 H 5 O 2 Na), 1.56mol nickel acetate (Ni(CH 3 COO) 2 ) And 6.24mol manganese acetate (Mn(CH 3 COO) 2 ) Add 60mL N,N-dimethylformamide (DMF), the molar ratio of nickel acetate to manganese acetate is 1:4, magnetically stir until it dissolves;

[0033] Step 2. Add 11 mol of terephthalic acid (BDC) and magnetically stir to dissolve to obtain a mixed solution;

[0034] Step 3. Add the mixed solution to the hydrothermal reaction kettle and react at 180° C. for 12 hours to obtain a mixed solution for generating metal organic framework compounds;

[0035] Step 4. Centrifuge the mixed solution in step 3, wash with DMF and absolute ethanol, and then vacuum dry at 80°C for 12 hours;

[0036] Step 5. Baking again at 700°C, the heating rate is 2.5°C / min, the baking time is 2h, and the obtained product includes a nickel-nitrogen doped carbon layer and manganese oxide...

Embodiment 2

[0046] The preparation steps of nickel-nitrogen co-doped porous carbon nanosheets are:

[0047] Step 1. Add 5.5mol sodium benzoate (C 7 H 5 O 2 Na), 0.39mol nickel acetate (Ni(CH 3 COO) 2 ) And 7.41mol manganese acetate (Mn(CH 3 COO) 2 ) Add 60mL N,N-dimethylformamide (DMF), the molar ratio of nickel acetate to manganese acetate is 1:9, magnetically stir to dissolve;

[0048] Step 2. Add 11 mol of terephthalic acid (BDC) and magnetically stir to dissolve to obtain a mixed solution;

[0049] Step 3. Add the mixed solution to the hydrothermal reaction kettle and react at 180° C. for 12 hours to obtain a mixed solution for generating metal organic framework compounds;

[0050] Step 4. Centrifuge the mixed solution in step 3, wash with DMF and absolute ethanol, and then vacuum dry at 80°C for 12 hours;

[0051] Step 5. Baking again at 700°C, the heating rate is 2.5°C / min, the baking time is 2h, and the obtained product includes a nickel-nitrogen doped carbon layer and manganese oxide;

[005...

Embodiment 3

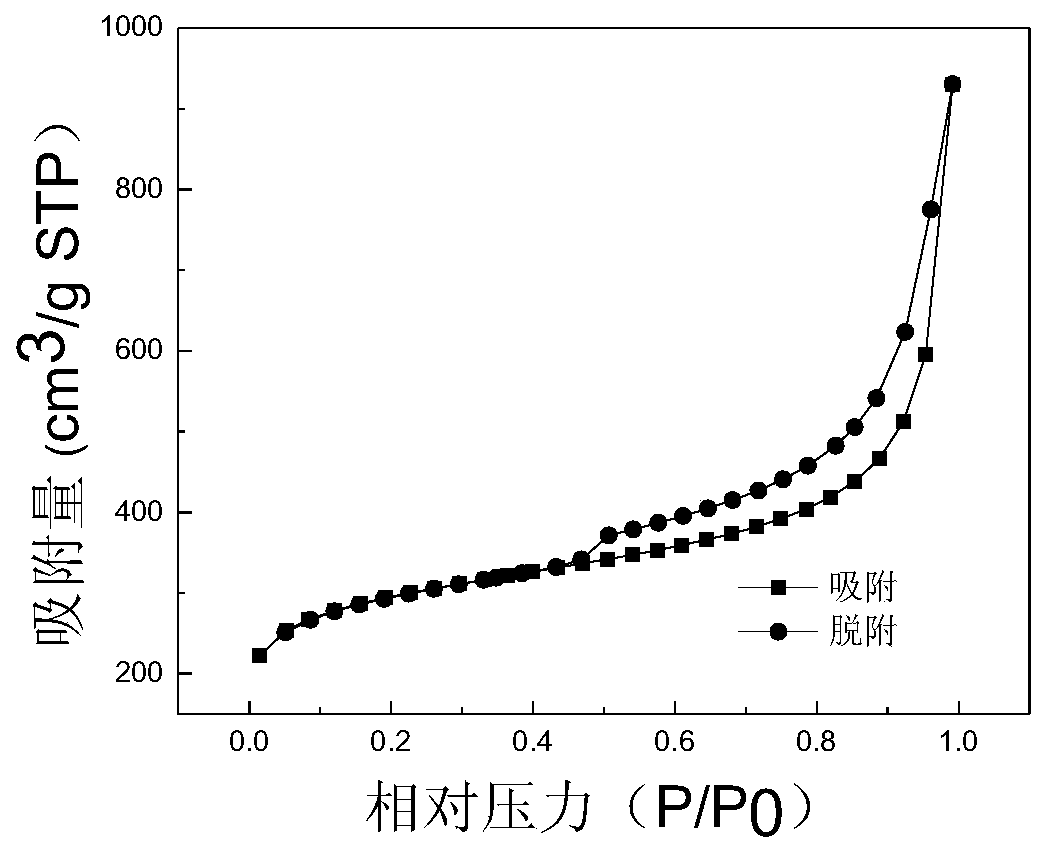

[0055] Like the nickel-nitrogen co-doped porous carbon nanosheets provided in Example 1, the molar ratio of nickel acetate to manganese acetate is 1:1.5. The heating temperature of the mixed solution B is 120°C, and the baking temperature is 600°C. The prepared nickel-nitrogen The BET specific surface area of the co-doped porous carbon nanosheets is 300m 2 / g.

[0056] As in Application Example 1, the nickel-nitrogen co-doped porous carbon nanosheets prepared in Example 3 are used as a catalyst to electrocatalyze CO reduction 2 The maximum Faraday efficiency for CO is about 85% (starting voltage is -0.5V).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com