High salinity wastewater incineration desalting system and treatment method thereof

A high-salt wastewater and high-temperature flue gas technology, which is applied in the direction of combustion methods, water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of high investment cost, uncontrollable oxygen concentration, and non-recoverable heat energy, etc. Simple, convenient for industrial application, and the effect of improving the precipitation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

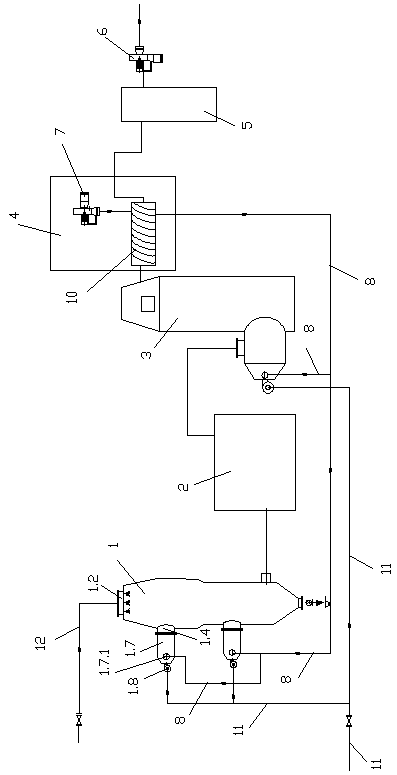

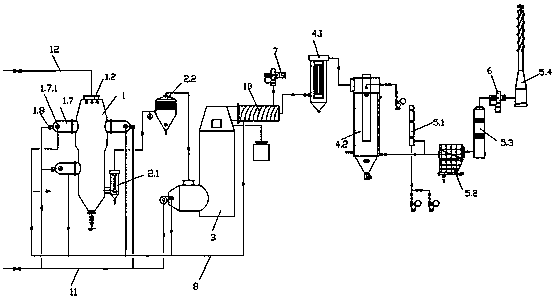

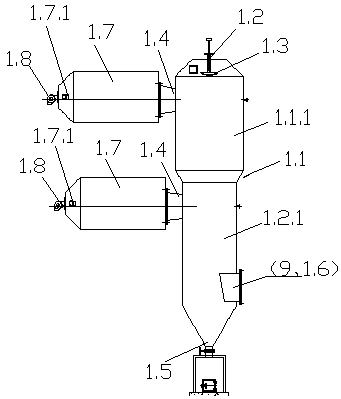

[0018] Example 1: A high-salt wastewater incineration and desalination system, including a drying reactor 1, a desalination device 2, a secondary combustion chamber 3, a waste heat recovery device 4, and a purification and discharge device 5. The air outlet of the drying reactor 1 is connected by a pipeline to remove The salt device 2, the air outlet pipe of the desalination device 2 is connected to the secondary combustion chamber 3, and the air outlet pipe of the secondary combustion chamber 3 is connected to the waste heat recovery device 4. The system is pumped into a vacuum and negative pressure state. The drying reactor 1 includes a vertical cylinder 1.1, a high-salt wastewater inlet 1.2 installed on the top of the vertical cylinder 1.1, and a pressurized atomization device 1.3 is installed on the high-salt wastewater inlet 1.2. The high-temperature flue gas inlet 1.4 on the vertical cylinder 1.1, the salt outlet 1.5 at the bottom of the vertical cylinder 1.1, the organic...

Embodiment 2

[0019] Embodiment 2: With reference to Embodiment 1, other structures remain unchanged, the high-temperature flue gas inlet 1.4 of the drying reactor 1 is opened tangentially along the vertical cylinder body 1, so that the high-temperature flue gas is formed along the inner wall of the vertical cylinder body 1.1 Spiral downward turbulence, desalination device 2 includes cyclone dust collector 2.1, high temperature cotton dust collector 2.2, waste heat recovery device 4 includes air heat exchanger 10, air inlet of air heat exchanger 10 is connected to oxygen supply fan 7, and The waste heat steam generator 4.1 connected to the flue gas outlet of the air heat exchanger 10, and the semi-dry quenching tower 4.2; the purification and discharge device 5 includes a mixing reactor 5.1, a bag filter 5.2, a neutralization scrubber 5.3, a smoke exhaust fan 6, an exhaust Inflator 5.4 etc.

Embodiment 3

[0020] Embodiment 3, with reference to Embodiment 2, other structures remain unchanged, the vertical cylinder body 1.1 is provided with an upper large-diameter section 1.1.1 and a lower small-diameter section 1.1.2, and high-temperature flue gas is provided on the cylinder wall of each cylinder body Air inlet 1.4, the high-temperature flue gas inlet 1.4 is provided with one around the center of each vertical cylinder 1.1, the organic gas outlet 1.6 is connected to the outlet pipe 9, and the connecting end of the outlet pipe 9 extends into the vertical cylinder 1.1, The port is close to the center of the vertical cylinder 1.1. The height from the bottom end of the pressurized atomization device 1.3 to the nearest high-temperature flue gas inlet 1.4 is 300mm~600mm. The range of height and diameter of the large and small diameter segments (1.1.1, 1.1.2) and the proportional relationship between them are 3 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com