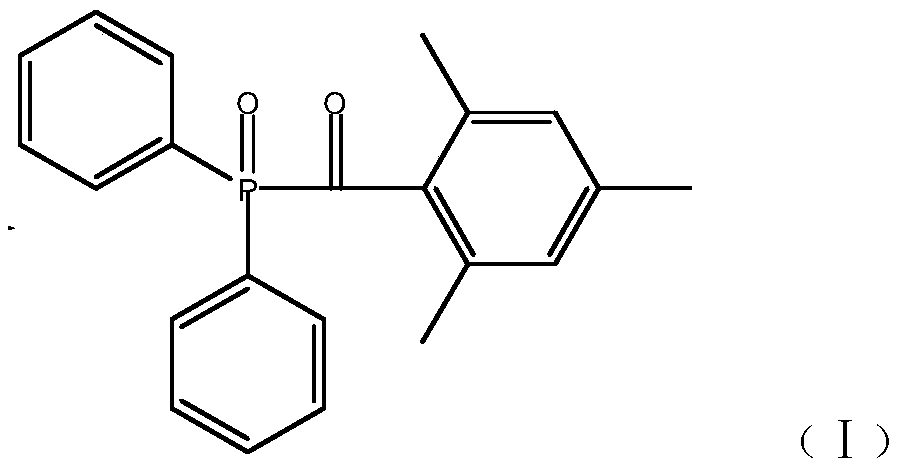

Novel synthesis method of clean and safe photoinitiator (2,4,6-trimethylbenzoyldiphenyl-diphenylphosphine oxide)

A technology of trimethylbenzoyl and diphenylphosphine oxide, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc. , easy to affect the progress of the reaction, the danger of the reaction process and other problems, to achieve the effect of simple synthesis process and post-processing steps, easy recovery and good reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A new synthetic method of a clean and safe photoinitiator 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, comprising the following synthetic steps:

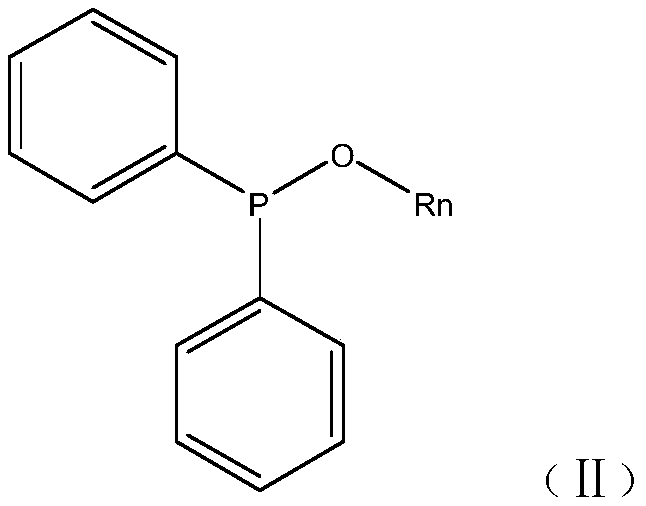

[0037] (1) Synthesis of diphenylalkoxyphosphine with general formula II: Add anhydrous alcohol and N-methylimidazole into the reactor at room temperature and mix evenly, heat up to 30-50°C, drop Add diphenylphosphine chloride. After the dropwise addition, heat up to 50-100°C and react at a constant temperature for 2-3 hours. Alkoxyphosphine.

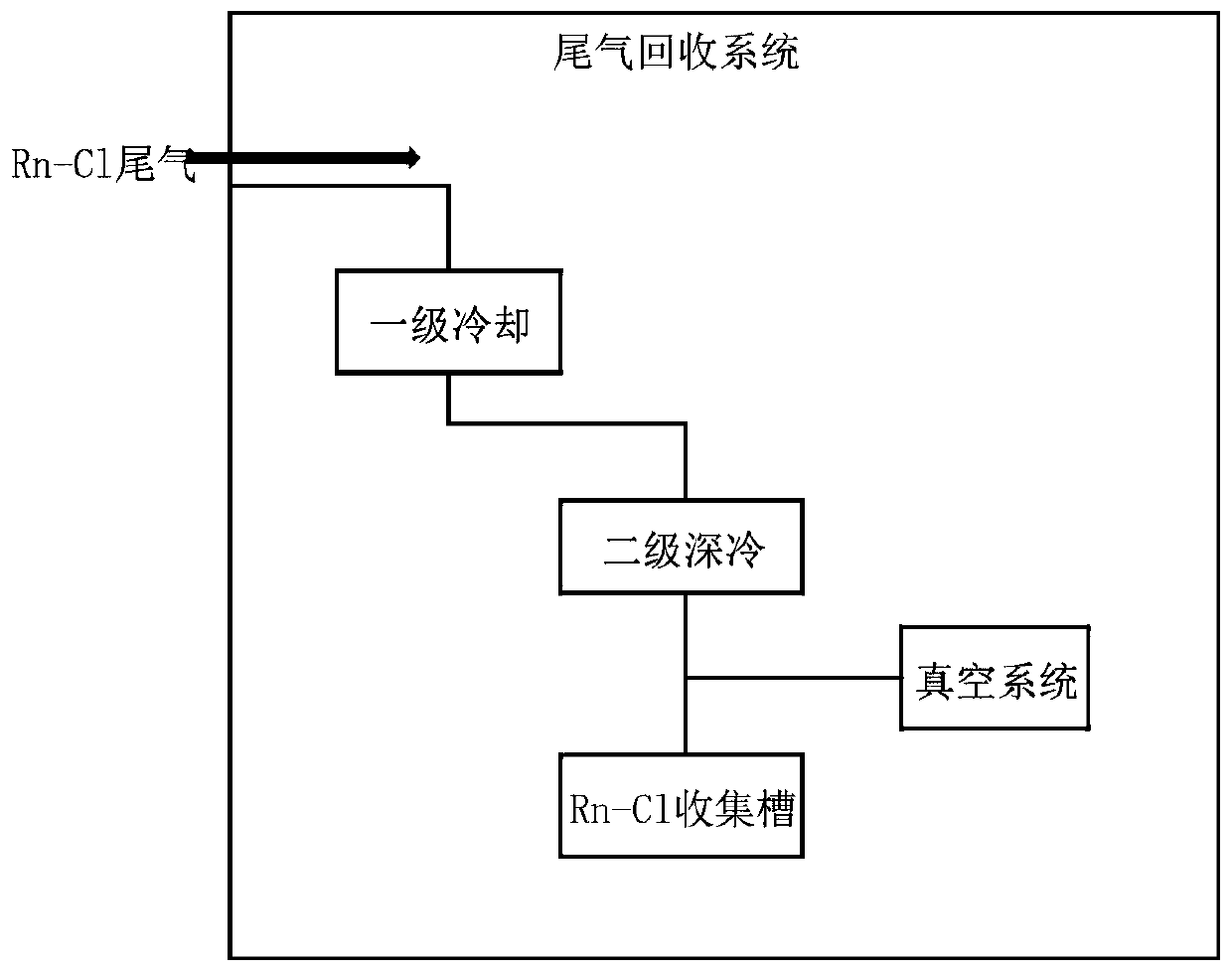

[0038] (2) Synthesis of photoinitiator 2,4,6-trimethylbenzoyl-diphenylphosphine oxide (TPO): the reaction vessel is evacuated to -0.098Mpa with a vacuum pump, under the vacuum condition of -0.098Mpa The intermediate product diphenylalkoxyphosphine and 2,4,6-trimethylbenzoyl chloride obtained in step (1) were added to the reaction vessel, and the temperature was controlled at 50°C to start the reaction. During the reaction, the temperature was raised for 10 minutes at intervals of 20...

Embodiment 1

[0042]Synthesis of diphenyl n-butoxyphosphine: Add 300g of N-methylimidazole and 400g of anhydrous n-butanol to a 2L four-neck flask, add 600g of diphenylphosphine chloride dropwise at a temperature of 45°C, and raise the temperature to 65°C Keep the temperature for 2 hours, after the reaction is completed, let stand to separate layers, take the supernatant, and distill to obtain 650 g of diphenylbutoxyphosphine.

[0043] The synthesis of TPO and the recovery of chlorobutane: use vacuum pump to vacuumize the reaction bottle to -0.098Mpa, under this condition, 258g diphenylbutoxyphosphine and 182.5g 2,4,6-trimethylbenzoyl chloride Put it into the reaction flask, control the temperature at 50°C to start the reaction, increase the temperature by 10°C every 20 minutes during the reaction process, until the temperature rises to 90°C, and then react at a constant temperature of 90°C for 8 hours, the tail gas chlorobutane generated during the reaction process is removed by vacuum To ...

Embodiment 2

[0046] Synthesis of diphenylisobutoxyphosphine: Add 300g of N-methylimidazole and 350g of anhydrous isobutanol to a 2L four-necked flask, add 600g of diphenylphosphine chloride dropwise at a temperature of 50°C, and raise the temperature to 65°C After the temperature was kept constant for 2 hours, the reaction was completed, and the layers were separated. The supernatant was taken and distilled to obtain 643 g of diphenylisobutoxyphosphine.

[0047] Synthesis of TPO and recovery of chloroisobutane: Use a vacuum pump to evacuate the reaction bottle to -0.098Mpa. Under this condition, 258g diphenylisobutoxyphosphine and 182.5g 2,4,6-trimethylbenzene Formyl chloride was added to the reaction flask, and the temperature was controlled at 50°C to start the reaction. During the reaction, the temperature was raised by 10°C every 20 minutes until the temperature rose to 90°C, and then the reaction was carried out at 90°C for 6 hours. The tail gas chloroisobutane produced during the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com