Halogen-free flame-retardant ethylene paste plasticizing process

A technology of ethylene and paste, which is applied in the field of polymer material production, can solve the problems of reduced transparency, poor thermal stability, and poor charring effect, and achieve the effect of expanding the application range and improving light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present invention adopts following steps:

[0038] (1) Clean the polyethylene resin pellets with a dilute ethanol solution, then add them into an ultrasonic device, ultrasonicate for 30-40min, and then dry them in a dust-free environment; the concentration of the dilute ethanol solution is 60%;

[0039](2) polyethylene resin pellets and polypropylene are added in the initial mixing equipment and fully mixed; the preferred ribbon mixer of the initial mixing equipment;

[0040] (3) The plasticizer is divided into two parts, and one part of the plasticizer is preheated and evenly sprayed into the above-mentioned polyethylene resin with an injector;

[0041] (4) Adjust the dispersant and another part of plasticizer into a slurry, and add it to the above mixture; after 15 minutes, add the remaining raw materials in turn, and discharge the material after mixing completely in the initial mixing equipment;

[0042] (5) Put the above mixture into an open mill for masticatio...

Embodiment 2

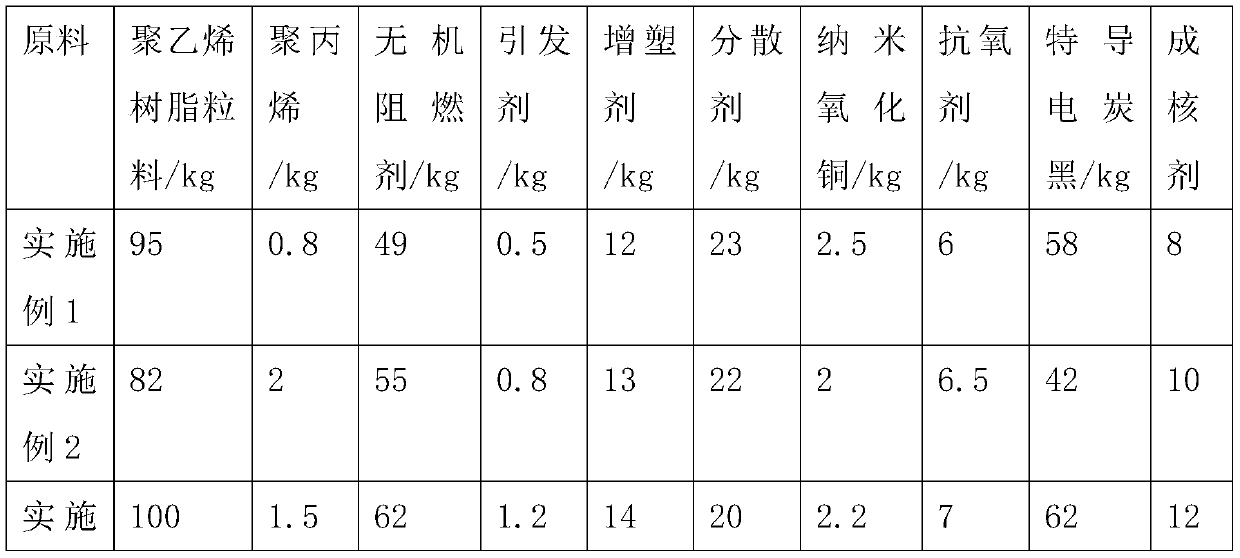

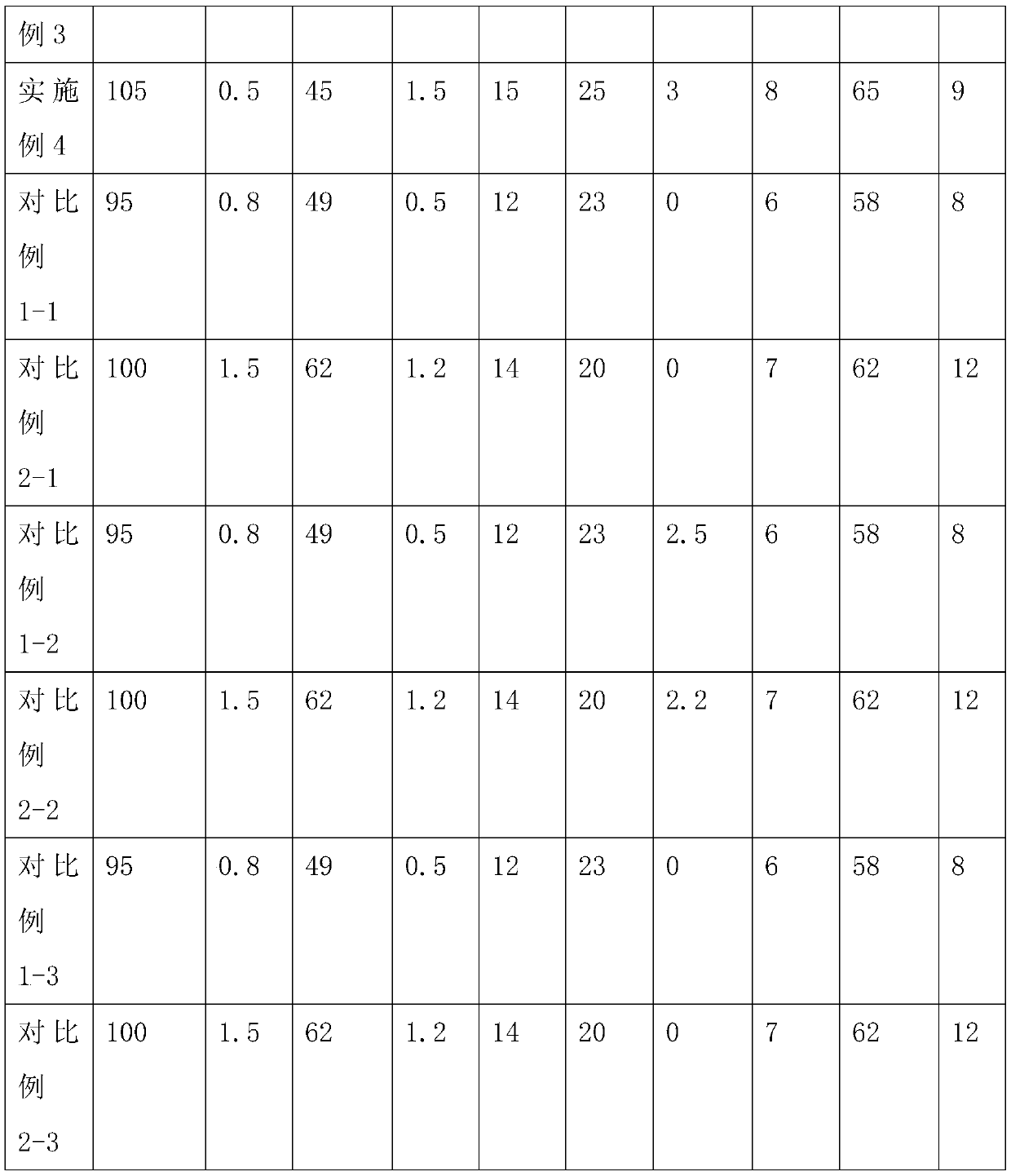

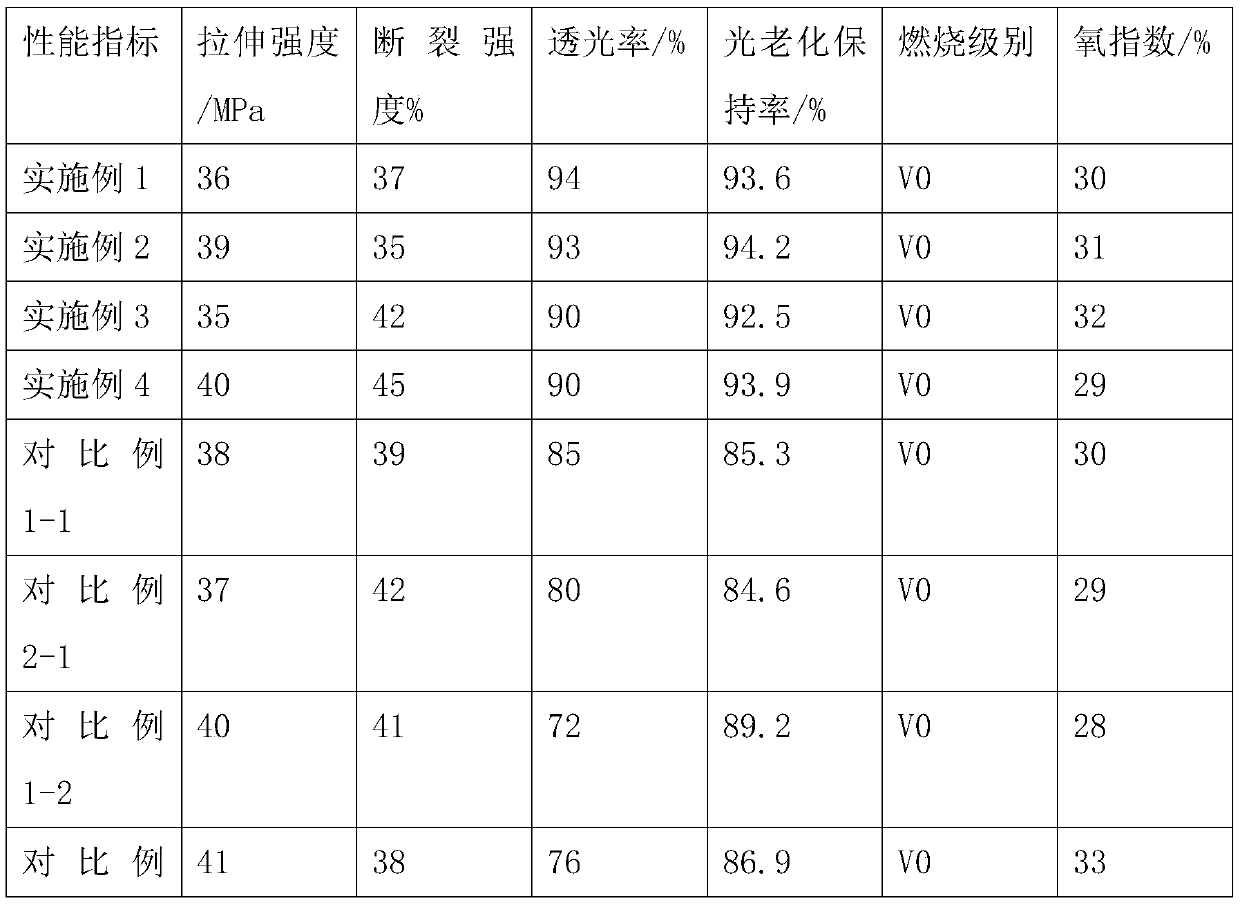

[0049] The dosage of each component in Example 2 is shown in Table 1, and the positive and negative electrode voltage strengths in step (7) are 130V; the rest are the same as in Example 1. The material prepared by the present invention is processed into a test sample bar according to the standard test requirements, and its performance is tested. The number of samples is five, and the average value is taken, which is listed in Table 2. All indicators are tested in accordance with the national standards for similar plastics.

Embodiment 3

[0051] The dosage of each component in Example 3 is shown in Table 1, and the positive and negative electrode voltage strengths in step (7) are 100V; the rest are the same as in Example 1. The material prepared by the present invention is processed into a test sample bar according to the standard test requirements, and its performance is tested. The number of samples is five, and the average value is taken, which is listed in Table 2. All indicators are tested in accordance with the national standards for similar plastics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com