Preparation method and application of rare earth luminescent complex

A rare earth luminescence and complex technology, applied in the measurement of color/spectral properties, etc., to achieve the effects of improved detection and diagnosis probability, high sensitivity and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

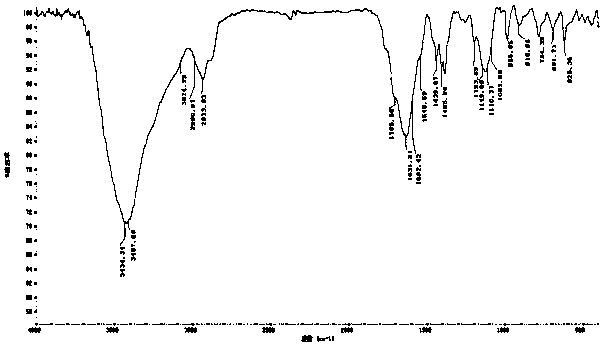

[0042] The preparation method of the rare earth luminescent complex of the present invention is as follows:

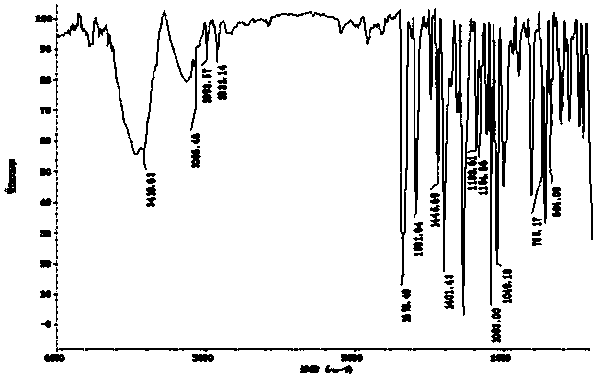

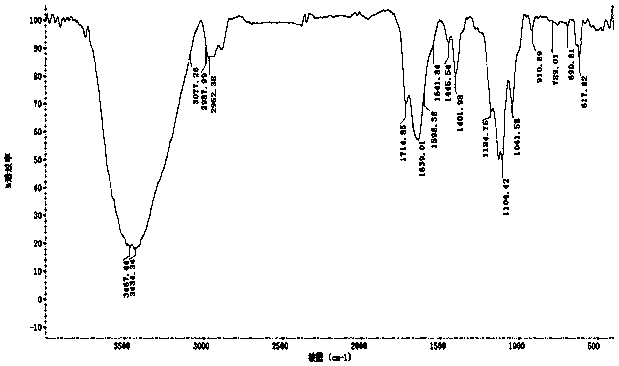

[0043] (1) Synthesis of thioether

[0044] Weigh 2.722g of sodium ethoxide solid and dissolve it in 100mL of absolute ethanol in a 250mL round-bottomed flask, add 4.968g of p-methylthiophenol and 8g of 2-bromoacetophenone in turn under mechanical stirring, and place it in a 65°C oil Stir under the bath for 1.5h, then add ice cubes to precipitate a milky yellow solid, filter it with suction, and dry it in a desiccator until constant weight. Add absolute ethanol to the crude product, put it in the refrigerator for recrystallization, and filter to obtain white needle-like crystals. Melting point mp: 38.5-39.5°C.

[0045]

[0046] (2) Synthesis of sulfoxide

[0047] At room temperature, dissolve 1.5 g of thioether in 50 mL of glacial acetic acid solution, add 1 mL of 30% H 2 o 2 ,, stirred for 12 hours, poured the obtained solution into water, extracted with ether,...

Embodiment 1

[0059] (1) Weigh 2.722g of sodium ethoxide solid and dissolve it in 100mL of absolute ethanol in a 250mL round bottom flask, add 4.968g of p-methylthiophenol and 8g of 2-bromoacetophenone in sequence under mechanical stirring, and place in Stir in an oil bath at 65°C for 1.5 hours, then add ice cubes to precipitate a milky yellow solid, filter it with suction, and dry it in a desiccator until constant weight. Add absolute ethanol to the crude product, put it in the refrigerator for recrystallization, and filter to obtain white needle-like crystals. Melting point mp: 38.5-39.5°C.

[0060] (2) At room temperature, dissolve 1.5g of thioether in 50mL of glacial acetic acid solution, add 1mL of 30% H 2 o 2 ,, stirred for 12 hours, poured the obtained solution into water, extracted with ether, and added water to wash repeatedly until the organic phase was neutral, and a large amount of white flocculent solids were precipitated at the same time, filtered by suction to obtain a whit...

Embodiment 2

[0068] The zero-grade tank of Streptomyces aureus, after the zero-grade tank of 5L is sterilized by high-temperature steam, the spore suspension of Streptomyces aureus on the inclined plane of a large test tube resurrected from the Streptomyces aureus strain storage room is inoculated with the following medium: soybean meal powder 5.0-8.0%; NaCl: 0.3-0.5%; corn steep liquor dry powder: 0.5-1.0%; maltose: 2.0-2.5%; fish oil: 3.5-4.0%; KH2PO4: 0.03-0.05%; ; The pH value is 6.8-7.2; the fermentation conditions are ventilation rate 1:1, stirring speed 150-200rpm, tank pressure 0.02MPa. Fermentation time 0~19h, take 100mL fermentation sample of fermented liquid from the zero-grade tank, ultracentrifuge the sample at 12000rpm, centrifugation time is 30min, take 100mL of supernatant each, and then add a certain amount of powder (particle size 200nm) Eu(pps-Si) 2 ·(ClO 4 ) 3 ·6H 2 O, after magnetic stirring for 30min, then nanofiltration to remove water, with a concentration of 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com