Porous electrode as well as conductive treatment method thereof

A porous electrode and electrode slurry technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of inability to control electrode morphology, large electrode internal resistance, poor conductivity of transition metal oxide activated carbon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

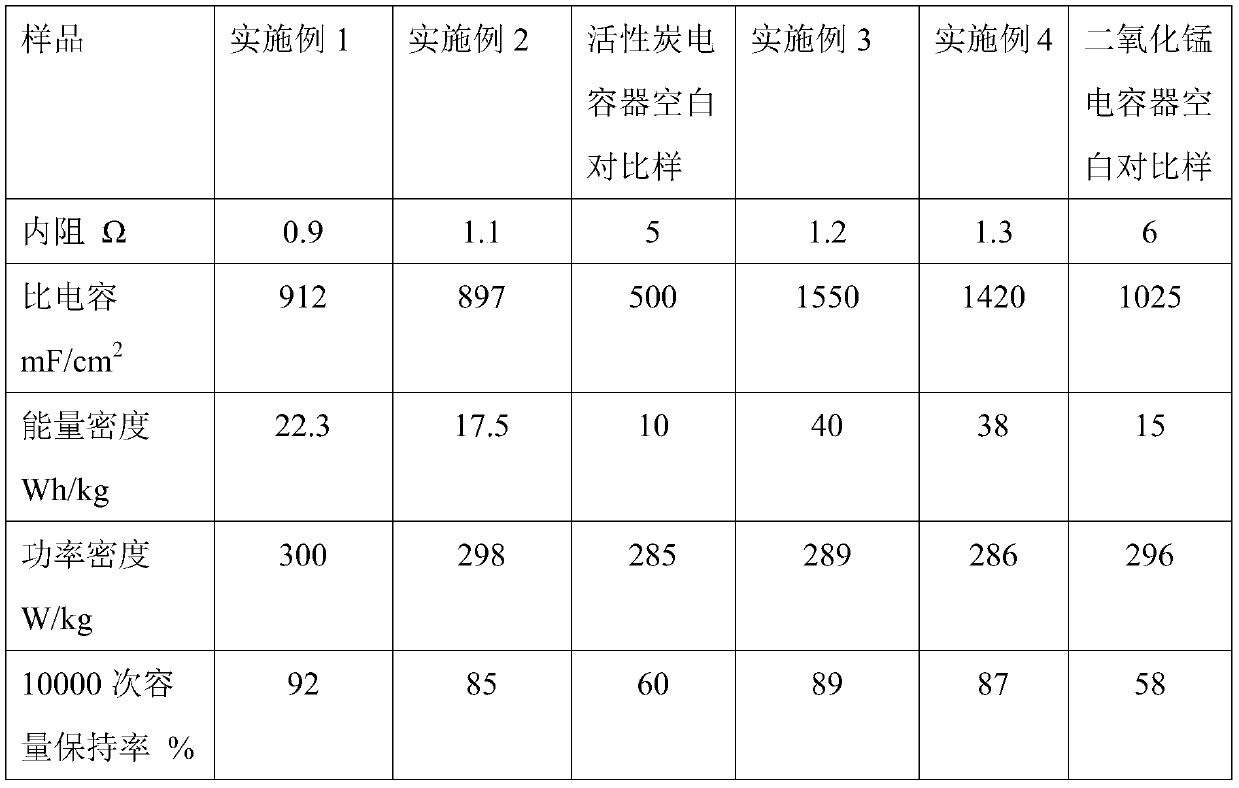

Examples

Embodiment 1

[0013] In the present invention, the preparation method of modified plant fiber and nano-cellulose regulating porous electrode is as follows:

[0014] (1): First weigh 80 g of PVA1788-acrylate copolymer grafted modified plant fibers and nanocellulose with a solid content of 5%, add 100 g of water and stir at high speed to disperse, and ultrasonicate at room temperature for 1 hour to obtain well-dispersed plant fibers. Then add 100g of 5% polyvinyl alcohol 1788 aqueous solution, 100g of 5% carboxymethylcellulose CMC solution, 15g of vinyl acetate-methyl methacrylate-butyl acrylate copolymer emulsion with 40% solid content and stir evenly, then add conductive 10g of carbon black, stir and disperse evenly, then add 70g of activated carbon, stir well and use it as electrode slurry for later use.

[0015] (2): Then, the dispersion system obtained in the step (1) is uniformly coated on the aluminum electrode sheet by a coating machine, and dried in hot air in a drying tunnel at 100°...

Embodiment 2

[0020] The preparation method of unmodified plant fiber regulation and control electrode porous structure among the present invention is as follows:

[0021] (1): First weigh 3.7g of bamboo fiber pulp board, add 100g of water and stir at high speed to disperse. Since the unmodified plant fiber is easy to agglomerate during ultrasonic treatment, add 2% nanocellulose in turn after about 5 minutes of ultrasonic treatment 15g, 100g of 5% polyvinyl alcohol 1788 aqueous solution, 100g of 5% carboxymethyl cellulose CMC solution, 15g of vinyl acetate-methyl methacrylate-butyl acrylate copolymer emulsion with 40% solid content, stir evenly, then add conductive carbon Black 10g, stir and disperse evenly, then add 70g of activated carbon, stir well and use as electrode slurry for later use.

[0022] (2): Then, the dispersion system obtained in the step (1) is uniformly coated on the aluminum electrode sheet by a coating machine, and dried in hot air in a drying tunnel at 100°C. The dry ...

Embodiment 3

[0027] In the present invention, modified plant fiber and nano-cellulose control nano-MnO 2 The preparation method of the porous electrode is as follows:

[0028] (1): First weigh 80 g of PVA1788-acrylate copolymer grafted modified plant fiber and nanocellulose with a solid content of 5%, add 220 g of water and stir at high speed to disperse, and obtain well-dispersed plant fiber after ultrasonic treatment at room temperature for 1 hour. Then add 60g of 5% polyvinyl alcohol 1788 aqueous solution, 140g of 5% carboxymethylcellulose CMC solution, 15g of vinyl acetate-methyl methacrylate-butyl acrylate copolymer emulsion with 40% solid content and stir evenly, then add conductive 10g of carbon black, stir and disperse evenly, then add 70g of nano-manganese dioxide, stir well and use it as electrode slurry for later use.

[0029] (2): Then, the dispersion system obtained in the step (1) is uniformly coated on the aluminum electrode sheet by a coating machine, and dried in hot air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com