Solar cell materials for increased efficiency

A technology of cations and absorbers, which is applied in the field of solar cell materials to improve efficiency, can solve the problems of high cost and lower battery efficiency, and achieve the effects of increasing efficiency, improving wettability, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

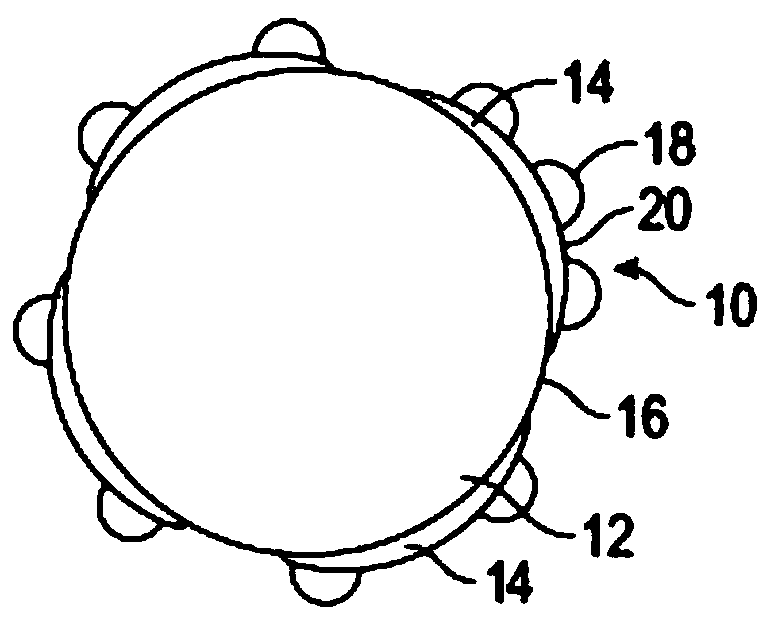

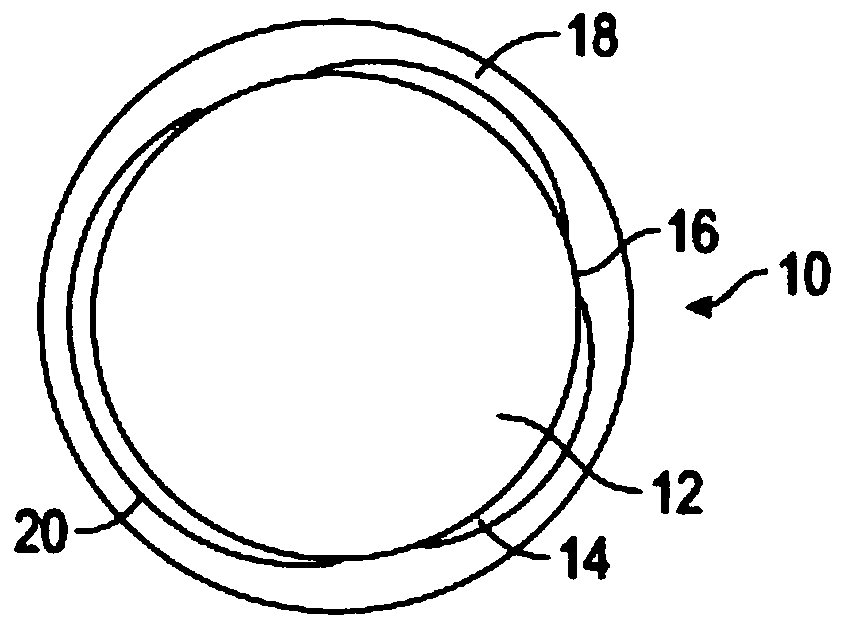

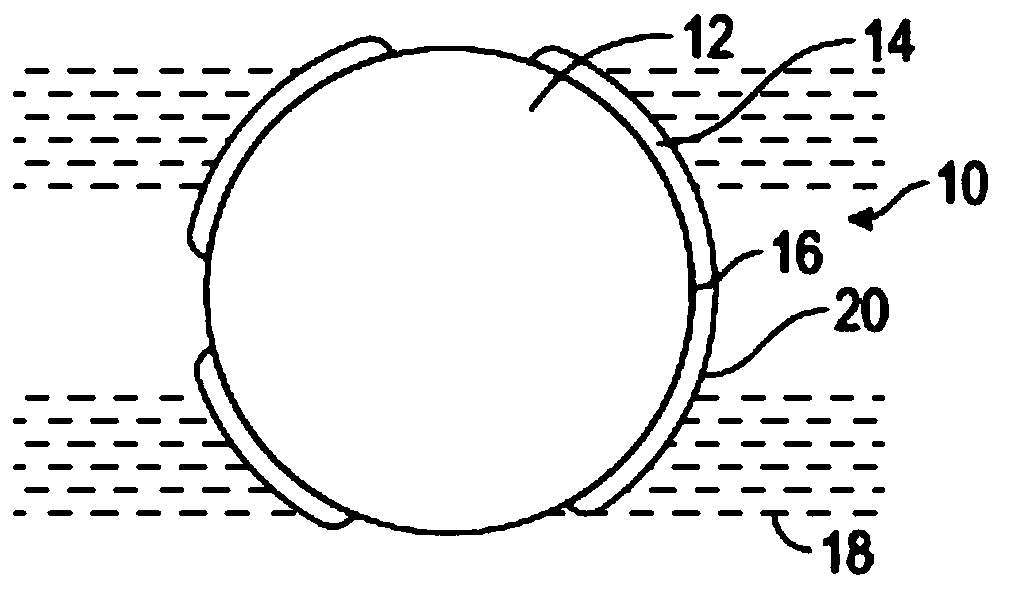

Image

Examples

Embodiment 1

[0124] Mesoporous titania gel (CristalACTiV washed before spray drying TM GP350 TM ), modified by treatment with hydrogen iodide to obtain a 5 mole percent iodide on titanium dioxide. CristalACTiV TM GP350 TM available from Cristal and are mesoporous titania nanoparticles. The gel was then dried at 105°C for 12 hours. The dried powder was ground in terpineol at 20% solids in a planetary mill. Put the unprocessed GP350 TM Dry and grind using the same conditions. Dry powder and untreated GP350 TM Neither contain water.

[0125] GP350 using a test cell with spray pyrolysis, 20 ml hand-polished fluorine-doped tin oxide (FTO) TM and iodide-modified GP350 TM Comparison; 40 wt% methylammonium lead triiodide (MALI) in DMSO+chlorobenzene; Spiro-MeOTAD plus FK209 TM LiTFSI 10% as hole transport material. FK209 TM LiTFSI is a complex lithium bis-trifluoromethanesulfonimide commercially available from DyeSol. The top electrode is 90nm gold. Multiple samples were tested ...

Embodiment 2

[0131] Use 1000g in 13% TiO 2 GP350 TM And placed under the mixer to prepare mesoporous titania gel. Then 5.57g lithium citrate was dissolved in 50g demineralized water. The lithium citrate solution was added to the stirring gel within 1 min. After the addition was complete, stirring was continued for 30 minutes. The doped gel was transferred to a glass tray, which was then placed in an oven at 105 °C for 24 h to dry. The glass tray is then removed from the oven and allowed to cool for 60 minutes before being placed on the PULVERISETTE using a 0.5mm sieve TM Grinding at a speed setting of 16 in a 14 rotor mill. The material is then transferred to a solid color container for storage during use. The material does not contain water.

[0132] The resulting GP350 doped with a 5% molar ratio (0.4 wt%) was then tested in a photovoltaic test cell as described above TM , and showed improved performance compared to untreated mesoporous titania.

Embodiment 3

[0134] Use 500g in 13% TiO 2 GP350 TM And placed under the mixer to prepare mesoporous titania gel. 11.6 g of lithium bis(trifluoromethane)sulfonimide salt (LiTFSi) were then dissolved in 50 g of demineralized water. Add the LiTFSi solution to the stirred gel within 1 min. After the addition was complete, stirring was continued for 30 minutes. The doped gel was transferred to a glass tray, which was then placed in an oven at 105 °C for 16 h to dry. The glass tray was then removed from the oven and allowed to cool for 60 minutes before grinding in a PULVERISETTE™ 14 rotor mill at a speed setting of 16 using a 0.5mm screen. The material is then transferred to a solid color container for storage during use. The material does not contain water.

[0135] The resulting GP350 doped with a 5% molar ratio (0.4 wt%) can then be tested in a photovoltaic test cell as described above TM , and showed improved performance compared to untreated mesoporous titania.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com