Deodorant spraying agent for paint coating and preparation technology of deodorant spraying agent

A technology for preparation process and spraying agent, which is applied in the field of deodorizing spraying agent for paints and coatings and its preparation, which can solve problems such as difficult release of peculiar smell, impact on human health, and impact on human health, and achieve the effect of excellent performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

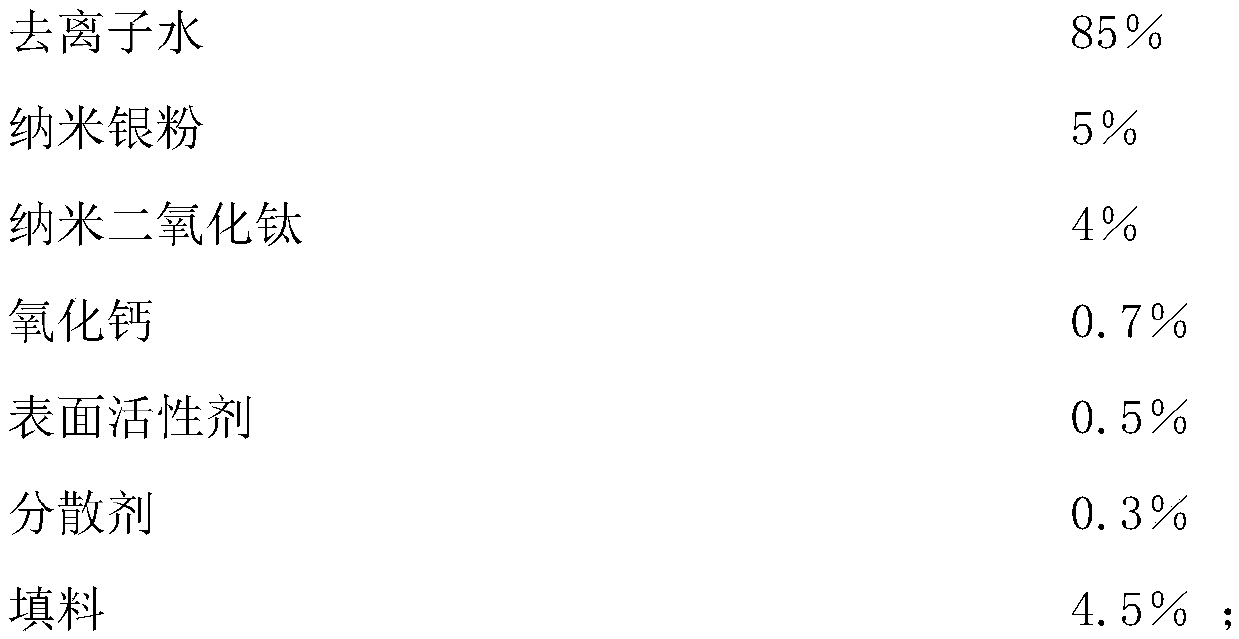

[0024] A kind of paint deodorizing spraying agent of the present invention and preparation technology thereof, its composition is as follows:

[0025]

[0026]

[0027] Further, the surfactant is fluorosurfactant FC-4430 or FC-4432.

[0028] Further, the dispersant is one, or a combination of two or more of phosphates, polyacrylates, and polycarboxylates.

[0029] Further, the filler is one, two or more combinations of calcium carbonate, talc, wollastonite, kaolin, silicon dioxide, barium sulfate and diatomaceous earth.

[0030] The above-mentioned product technological process: comprises the following steps,

[0031] S1) Weigh the following components respectively by the following mass percentages;

[0032]

[0033] S2) Pour the nano-silver powder, nano-titanium dioxide and calcium oxide weighed according to weight into deionized water and slowly stir, stir for 5-10 minutes, mix into a liquid, and pour the surfactant into the stirring tank together, stir and disper...

Embodiment 2

[0035] The above-mentioned product technological process: comprises the following steps,

[0036] S1) Weigh the following components respectively by the following mass percentages;

[0037]

[0038]

[0039] S2) Pour the nano-silver powder, nano-titanium dioxide and calcium oxide weighed according to weight into deionized water and slowly stir, stir for 5-10 minutes, mix into a liquid, and pour the surfactant into the stirring tank together, stir and disperse evenly; Add filler and dispersant to the discharged mixture and disperse evenly in the disperser to obtain the finished product.

Embodiment 3

[0041] The above-mentioned product technological process: comprises the following steps,

[0042] S1) Weigh the following components respectively by the following mass percentages;

[0043]

[0044] S2) Pour the nano-silver powder, nano-titanium dioxide and calcium oxide weighed according to weight into deionized water and slowly stir, stir for 5-10 minutes, mix into a liquid, and pour the surfactant into the stirring tank together, stir and disperse evenly; Add filler and dispersant to the discharged mixture and disperse evenly in the disperser to obtain the finished product.

[0045] The invention is mainly aimed at the shallow surface baking varnish or paint substances containing aromatic hydrocarbons, alkanes and ester ethers in unsaturated resins, which are difficult to degrade organic macromolecule odors by using photocatalysts. It can quickly react with aromatic hydrocarbons and alkanes of odorous macromolecules and overflow without residue, does not corrode metals,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com