Bone scaffold material as well as preparation method and application thereof

A technology of bone scaffold and composite material, which is applied in the field of high-strength bone scaffold material and its preparation, can solve the problems of high preparation cost and low compressive strength, and achieves the effects of short time consumption, low requirements, and favorable cell adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A first aspect of the present invention provides a method for preparing a bone scaffold material, wherein the method comprises the following steps:

[0037] (A) 3D direct-writing printing of biocompatible materials to make a bone scaffold structure;

[0038] (B) forming, drying and modifying the obtained bone scaffold structure to obtain a bone scaffold material,

[0039] Wherein, the biocompatible material, based on the total weight of the material, contains 12-26% by weight of hydroxyapatite, 3-16% by weight of silk fibroin, 0.5-2% by weight of sodium alginate and 65-75% water by weight.

[0040] According to the method of the present invention, the preparation method of the biocompatible material comprises: a composite material of 15-32.5 parts by weight of silk fibroin and hydroxyapatite, 0.5-2 parts by weight of sodium alginate, 2-8 The silk fibroin protein in parts by weight and water in 65-75 parts by weight are mixed and stirred.

[0041] According to the met...

preparation example 1

[0072] Preparation of silk fibroin:

[0073] Prepare 1500ml of sodium carbonate solution with a mass fraction of 0.5% in a beaker, heat until the solution boils slightly, add 15g of silk, stir with a glass rod for 0.5h, rinse with deionized water until it is not sticky, repeat the above process for secondary degumming, degumming Then dry naturally. Take the weight after degumming. Then add 13.8g of degummed silk fibroin to the ternary system of calcium chloride, ethanol and water with a molar ratio of 1:2:8, dissolve at a constant temperature of 60°C for 2 hours, and add 1.5 times deionized water after dissolution (heated to 60°C), cooled to room temperature, filtered through a filter membrane, and put into a dialysis bag for dialysis for 3-5 days.

preparation example 2

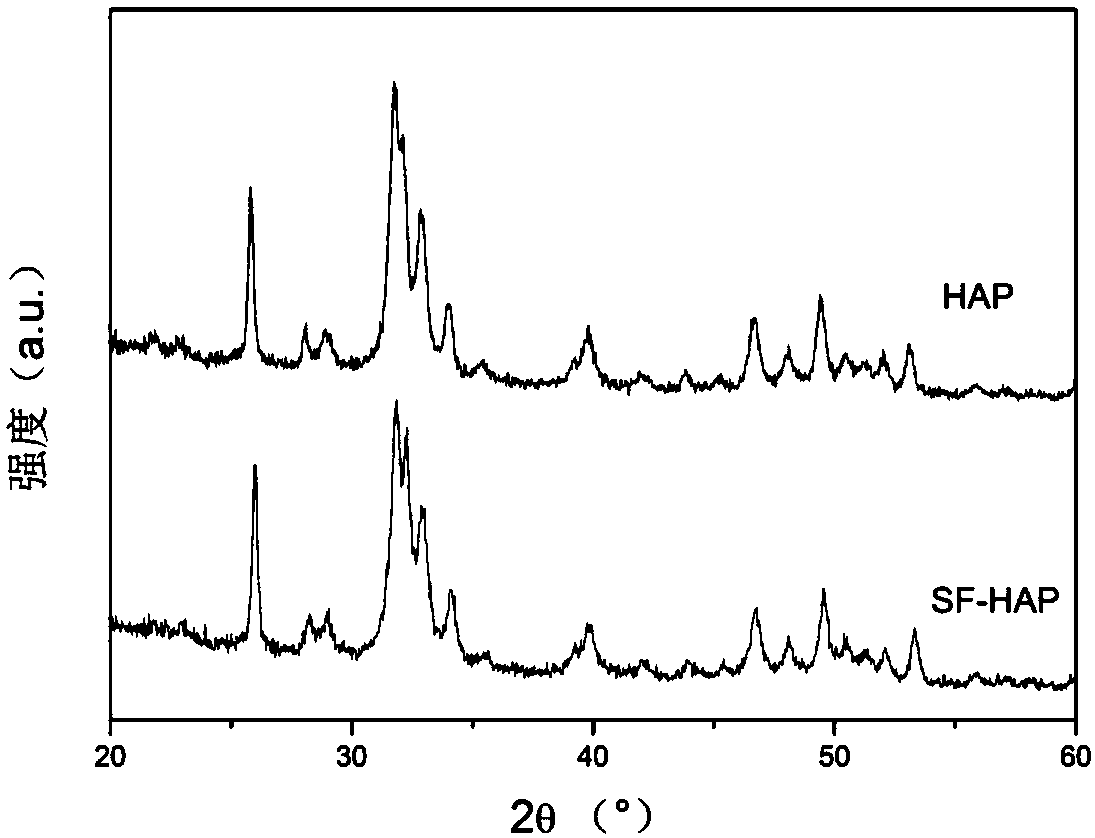

[0075] Preparation of composite material of silk fibroin and hydroxyapatite (SF-HAP)

[0076] After soaking 15g of silk in 0.5% sodium carbonate solution (at a temperature of 90° C.) for 0.5 h by mass fraction, rinse with deionized water; silk fibroin. Weigh 3.25g of degummed silk fibroin and dissolve it in 36.5ml of a ternary system of calcium chloride, ethanol and water with a molar ratio of 1:2:8 at a temperature of 60°C; the degummed silk fibroin After complete dissolution, adjust the temperature to 75°C, and add diammonium hydrogen phosphate aqueous solution dropwise. The addition amount of diammonium hydrogen phosphate aqueous solution satisfies: based on Ca element in calcium chloride, based on P element in diammonium hydrogen phosphate aqueous solution, the consumption of diammonium hydrogen phosphate aqueous solution satisfies the molar ratio of Ca / P being 1.67. Along with continuously adding the diammonium hydrogen phosphate aqueous solution, white turbidity appear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com