Method for adjusting morphology, band gap and stability of bismuth iodide-ethylene diamine hybrid material through doping projects

A hybrid material, ethylenediamine technology, applied in chemical instruments and methods, polycrystalline material growth, preparation of organic compounds, etc., can solve problems such as easy oxidation and deterioration, achieve good industrialization prospects, simple synthesis process, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

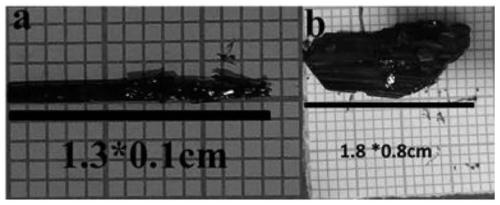

Embodiment 1

[0020] (1) Use a graduated cylinder to measure 10.00 mL of ethylenediamine solution and pour it into a three-necked flask, and stir in an ice-water bath;

[0021] (2) Slowly dripping 45.00 mL of concentration into the three-necked flask in step (1) is a 45% hydriodic acid solution, and magnetically stirred for 2 hours to obtain a suspension;

[0022] (3) Pour the suspension in step (2) into a petri dish, and dry it by blasting at 60°C for 20 hours to obtain white crystals;

[0023] (4) The white crystals obtained in step (3) were washed twice with 35.00 mL of ether, put into a petri dish, and then vacuum-dried at 60° C. for 20 hours to obtain white powder A;

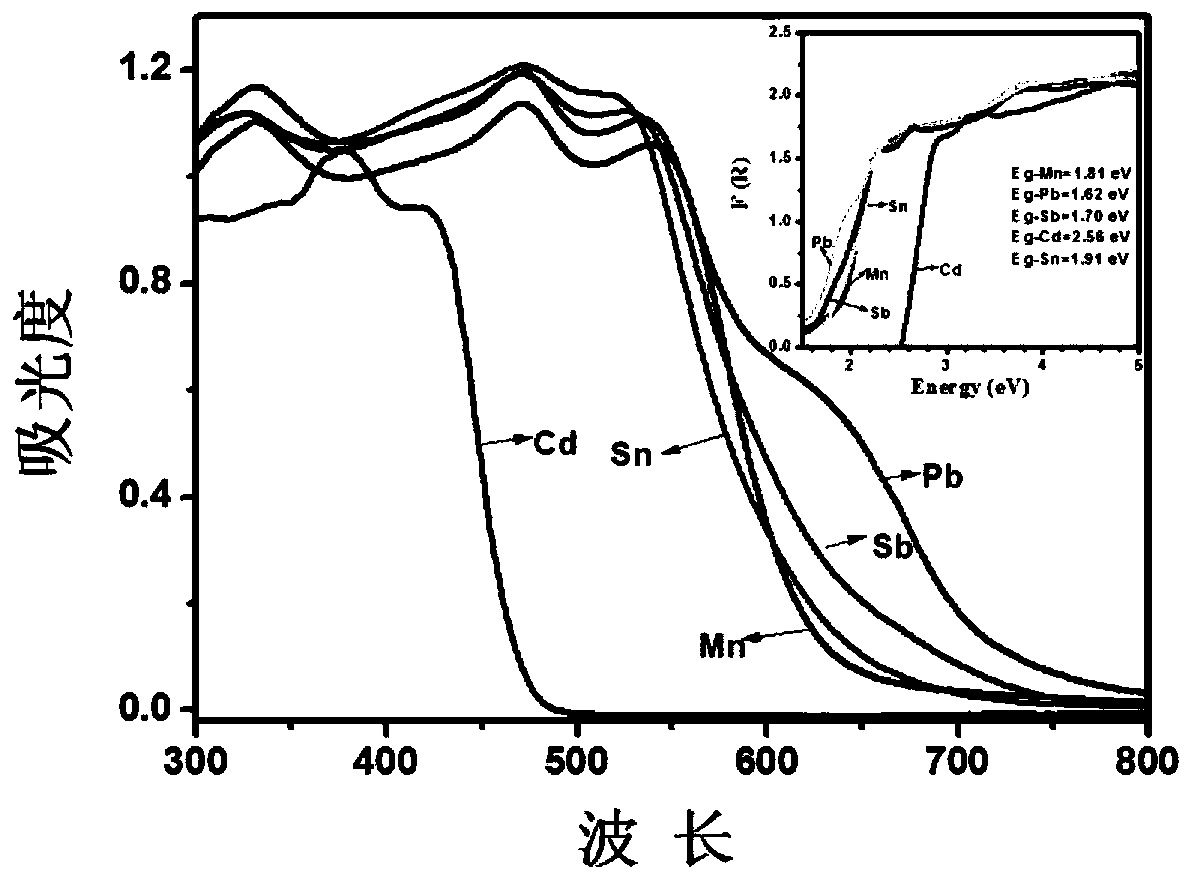

[0024] (5) Weigh Bi with a molar ratio of 2:1 2 o 3 and manganese iodide into the sample bottle, followed by adding 10mL of 45% hydroiodic acid solution to obtain a brownish red clear solution;

[0025] (6) Weigh 12.00mmol step (4) white powder A and join in the brown-red clear solution of step (5);

[0026] (7) Put ...

Embodiment 2

[0028] (1) Measure 12mL of ethylenediamine solution with a graduated cylinder and pour it into a three-necked flask, and stir in an ice-water bath;

[0029] (2) Slowly add 50.00 mL of hydriodic acid solution dropwise to the three-necked flask in step (1), and magnetically stir for 4 hours to obtain a suspension;

[0030] (3) Pour the suspension in step (2) into a petri dish, and dry it by blasting at 70° C. for 25 hours to obtain white crystals;

[0031] (4) The white crystals obtained in step (3) were washed 3 times with 45.00 mL of ether, put into a petri dish, and then vacuum-dried at 75° C. for 25 hours to obtain white powder A;

[0032] (5) Weigh Bi with a molar ratio of 2:3 2 o 3 and lead iodide were added to the sample bottle, followed by the addition of 30 mL of 45% hydroiodic acid solution to obtain a brownish-red clear solution;

[0033] (6) Weigh 14.00mmol step (4) white powder A and join in the brown-red clear solution of step (5);

[0034] (7) Put the reaction...

Embodiment 3

[0036] (1) Use a graduated cylinder to measure 15.00 mL of ethylenediamine solution and pour it into a three-necked flask, and stir in an ice-water bath;

[0037] (2) Slowly add 60.00 mL of 45% hydriodic acid solution dropwise to the three-necked flask in step (1), and stir magnetically for 5 hours to obtain a suspension;

[0038] (3) Pour the suspension in step (2) into a petri dish, and dry it by blasting at 80° C. for 30 hours to obtain white crystals;

[0039] (4) The white crystals obtained in step (3) were washed 4 times with 55.00 mL of ether, put into a petri dish, and then vacuum-dried at 80° C. for 30 hours to obtain white powder A;

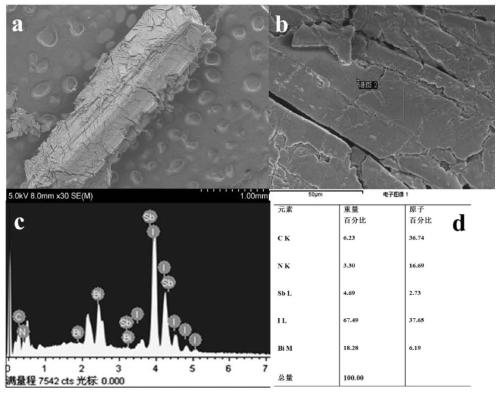

[0040] (5) Weigh Bi with a molar ratio of 2:5 2 o 3 and antimony iodide into the sample bottle, followed by adding 20mL of 45% hydriodic acid solution to obtain a brownish red clear solution;

[0041] (6) Weigh 15.00mmol step (4) white powder A and join in the brown-red clear solution of step (5);

[0042] (7) Put the reaction solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com