A kind of functional shape memory composite material and its preparation method and application

A composite material and functional technology, applied in the field of composite materials, can solve the problems of low mechanical strength of the coating layer, limited development and application, complex preparation methods, etc., achieve good commercial application value, controllable temperature response range, and preparation methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

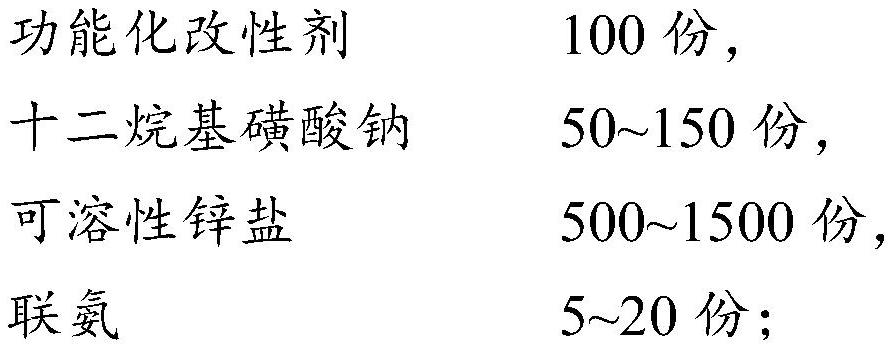

[0069] Preparation of zinc oxide / sodium dodecylsulfonate / carbon nanotube ternary functional modifier.

[0070] Mix 0.05mol / L sodium dodecylsulfonate aqueous solution with carbon nanotubes and sonicate for 2 hours. After the sonication is completed, add 0.3mol / L zinc chloride aqueous solution, continue to sonicate for 3 hours, and then add 0.2mol / L hydrogen Sodium oxide aqueous solution, finally add hydrazine aqueous solution with a water content of 50%, react in an oil bath at 100°C for 24 hours, and form a black dispersion, centrifuge, wash with deionized water and ethanol alternately, and vacuum dry to obtain zinc oxide / dodecane Sodium sulfonate / carbon nanotube ternary functional modifier.

[0071] The mass ratio between carbon nanotubes, sodium dodecylsulfonate, zinc chloride, sodium hydroxide and hydrazine in the above-mentioned preparation process is:

[0072]

Embodiment 2

[0074] The zinc oxide / sodium dodecylsulfonate / carbon nanotube of Example 1 was used as a three-component functional modifier.

[0075] Weigh 100 parts by mass of trans-1,4-polyisoprene TPI-301 (TPI for short) and 0.002 parts by mass of a ternary functional modifier. First, the ternary functional modifier was ultrasonicated in 800 parts by mass of toluene for 1 h, then mixed with TPI and crosslinking agent and added into a three-necked flask, heated and stirred in an oil bath at 60° C. for 2.5 h at a stirring speed of 250 rpm. Then pour the stirred mixture into a Petri dish and dry it on a hot table at 100°C for 3 days. After drying, place it in a mold of 100mm×100mm×1mm and vulcanize it on a flat vulcanizer at 160°C and a pressure of 12MPa. After 20 minutes, a functional shape memory composite material of 100mm×100mm×1mm was finally obtained.

[0076] The transition temperature of the obtained functional shape memory composite material is 50-70°C, the shape recovery ratio is ...

Embodiment 3

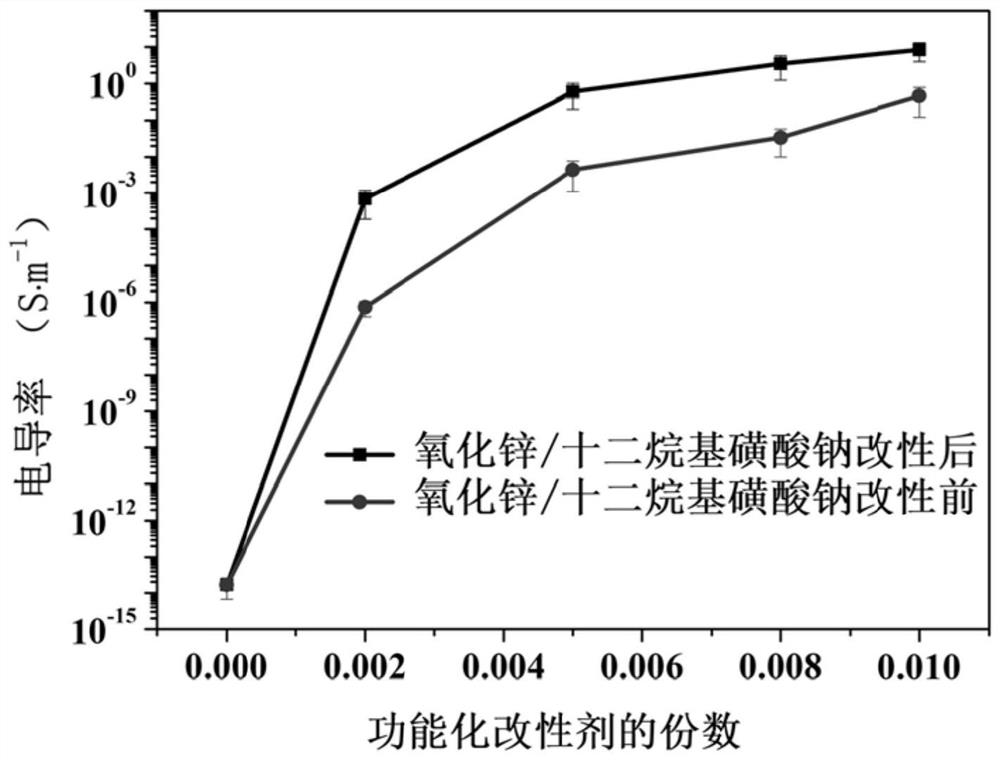

[0078] The difference from Example 2 is only that 0.005 parts by mass of the ternary functional modifier is weighed, and the rest of the steps are the same, the transition temperature of the obtained functional shape memory composite material is 50-70°C, and the shape recovery ratio is 95% ~98%, the fixed ratio is 95%~97%, and the conductivity of the material is 0.61S / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| draft ratio | aaaaa | aaaaa |

| draft ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com