High-temperature-resistant heat-conducting paint and preparation method thereof

A heat-conducting coating and high-temperature-resistant technology, applied in the field of coatings, can solve problems such as poor thermal conductivity and temperature rise of the hub, and achieve the effects of good fatigue resistance, high axial strength and modulus, and excellent electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

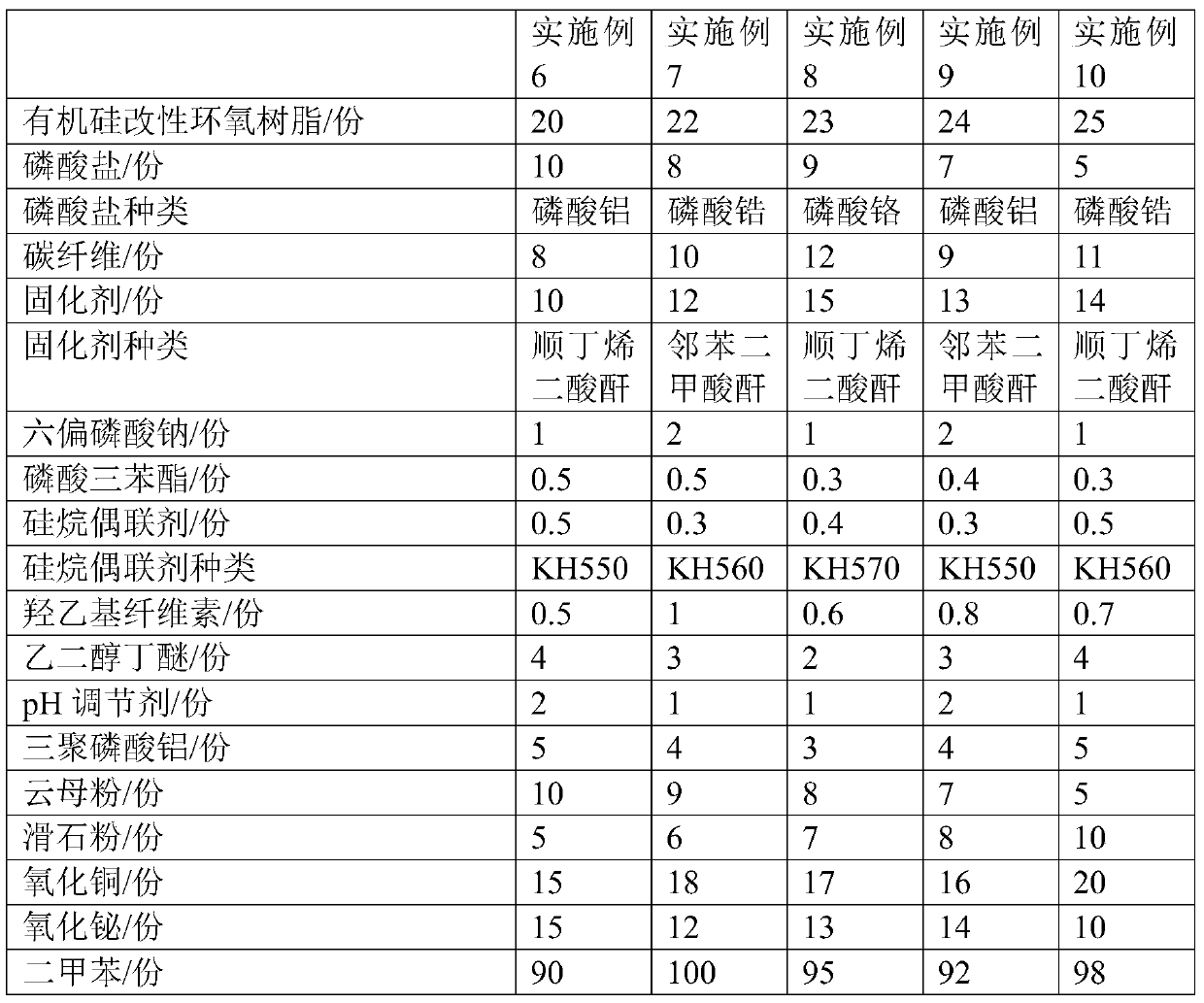

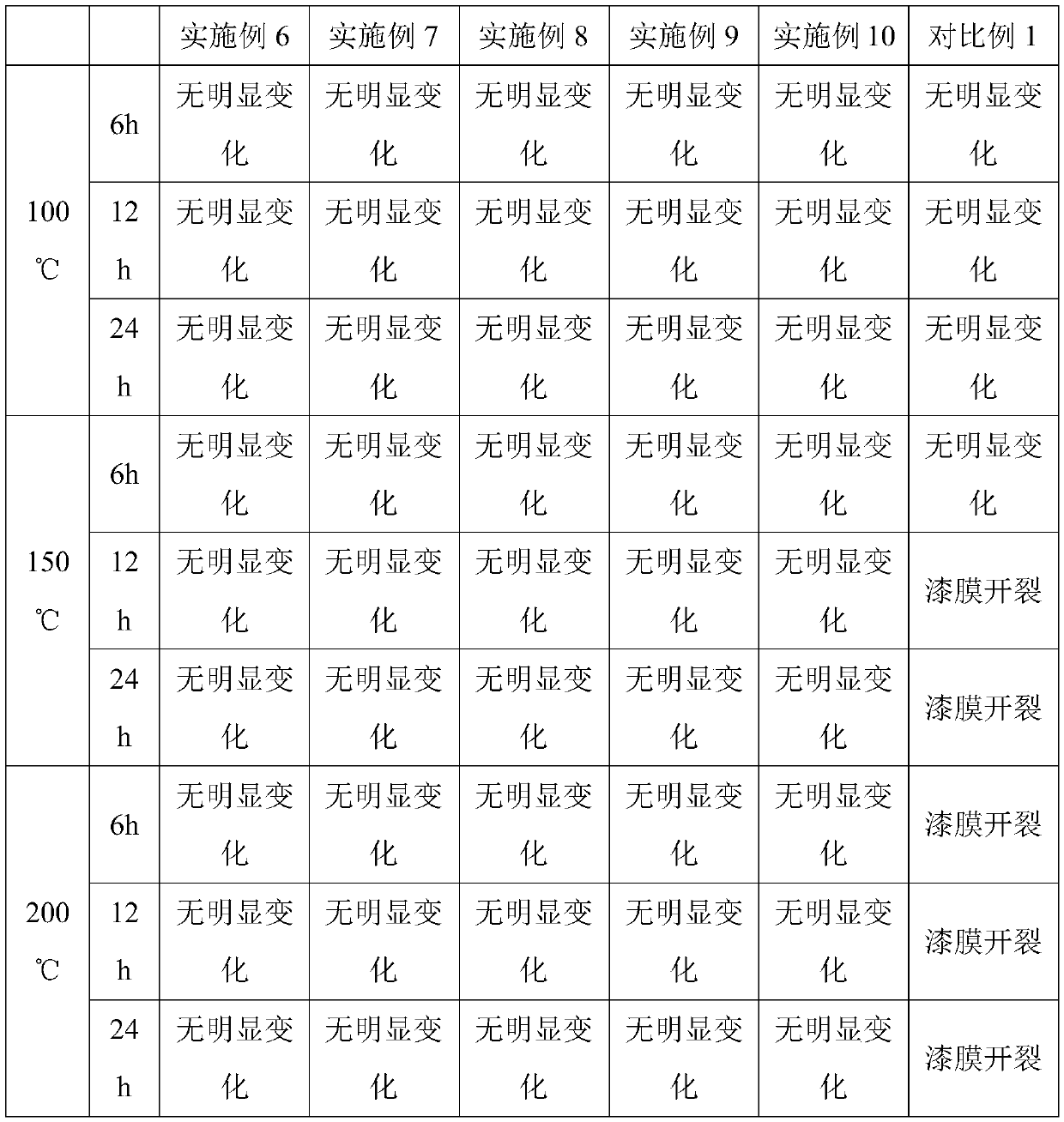

Examples

preparation example Construction

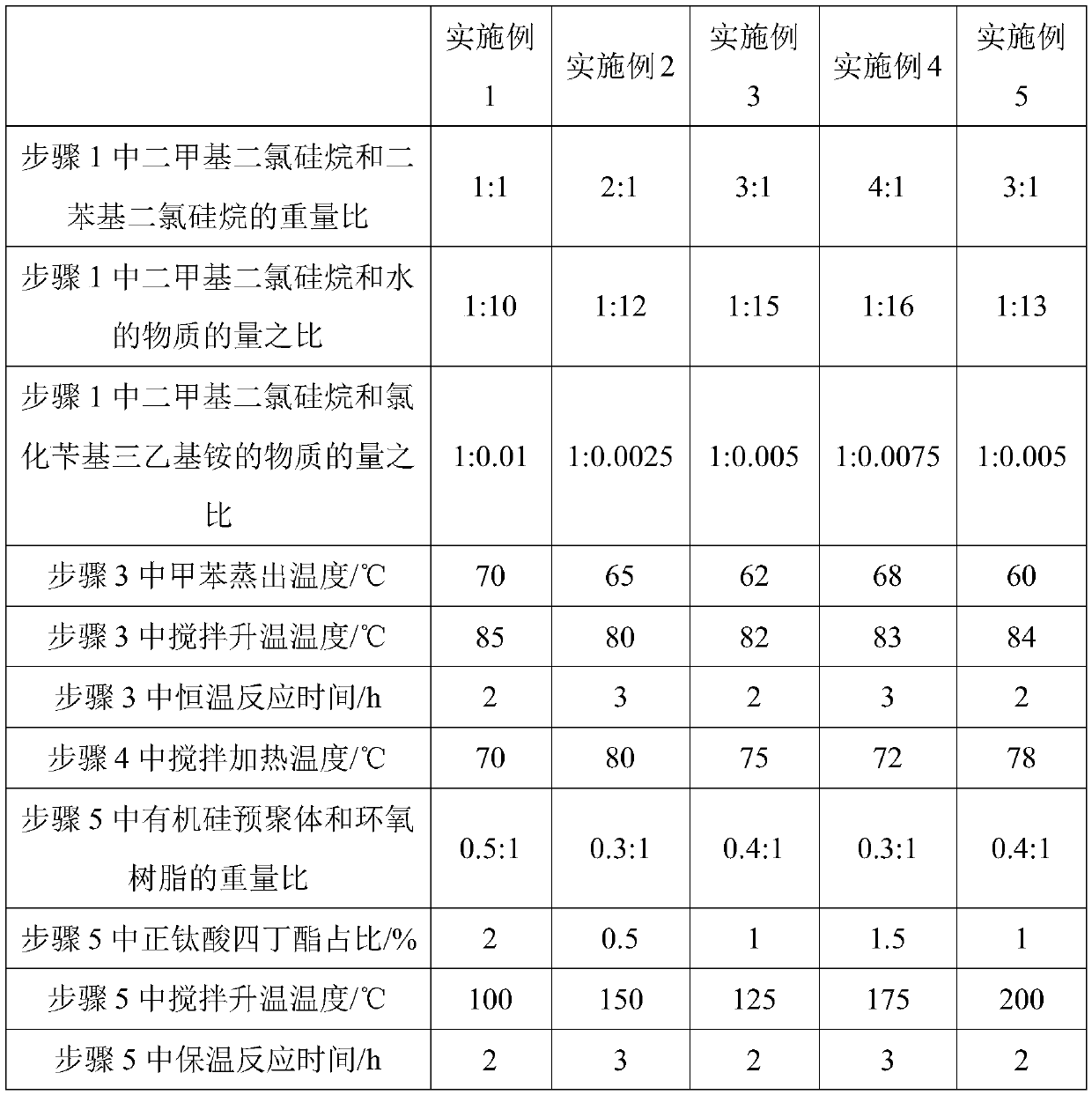

[0054] A preparation method of organosilicon modified epoxy resin, comprising the steps of:

[0055] Step 1: Add dimethyldichlorosilane, diphenyldichlorosilane, water, toluene and benzyltriethylammonium chloride successively, the weight ratio of said dimethyldichlorosilane and diphenyldichlorosilane is 1-4:1, the ratio of the amount of dimethyldichlorosilane to water is 1:10-16, and the mass volume ratio of dimethyldichlorosilane to toluene is 0.1g / mL; The ratio of the amount of substance of the dimethyldichlorosilane and benzyltriethylammonium chloride is 1: 0.0025-0.01:

[0056] Step 2: After the addition is complete, let stand to separate the water layer, wash the solvent layer with water, let stand again to separate the water layer, and then titrate to neutrality with 0.1mol / L sodium hydroxide solution;

[0057] Step 3: Distill the toluene under reduced pressure at 60-70°C, under the protection of nitrogen, stir and raise the temperature to 80-85°C, then add n-propanol with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com