Method for recovering positive electrode material waste of lithium ion battery and regenerating positive electrode material of lithium ion battery

A lithium-ion battery and cathode material technology, applied in the recycling and regeneration of lithium-ion battery cathode material waste, can solve the problems of high organic acid price, low process route, and unfound cost, and achieve short leaching time and high reactivity , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

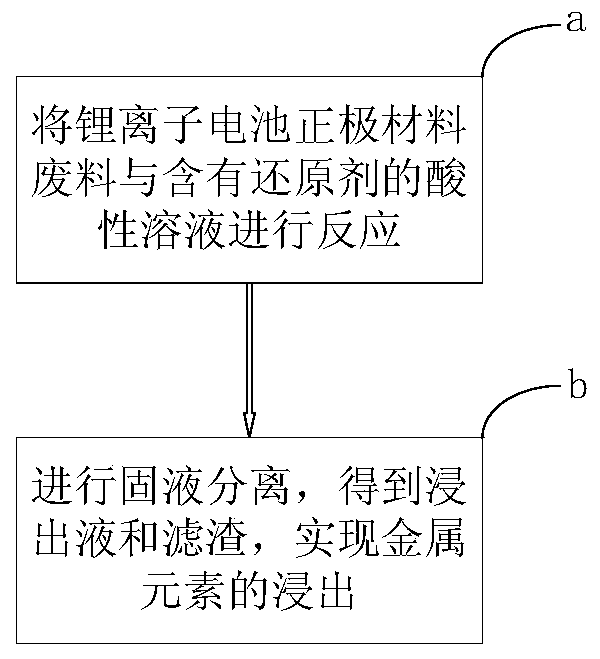

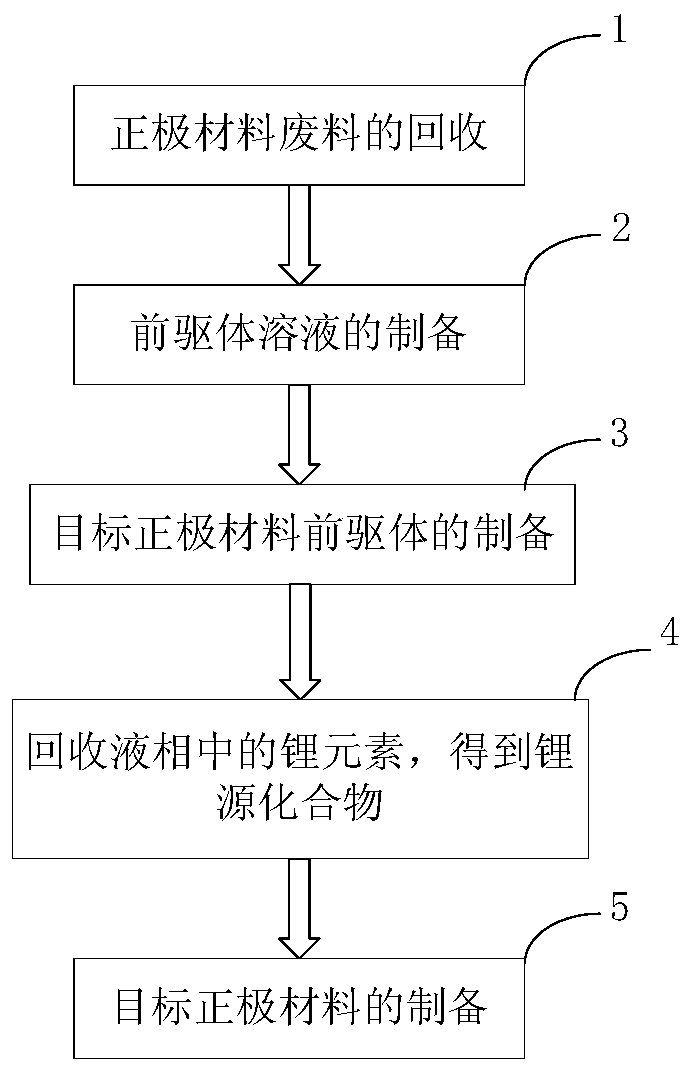

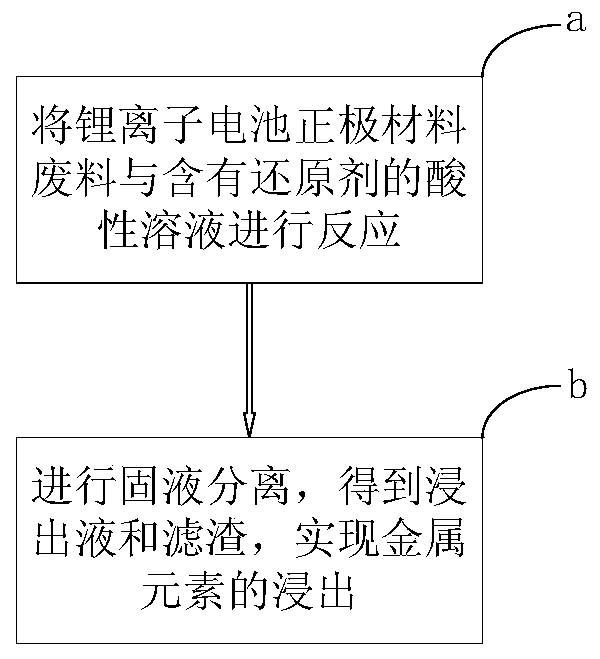

[0091] Take a few pieces of waste lithium-ion secondary batteries for electric vehicles, the chemical formula of the positive electrode active material is LiNi 0.5 co 0.2 mn 0.3 o 2 . Disassemble the battery after immersing the battery in salt water, and dissolve the electrolyte remaining in the pole piece by solvent immersion, dry the pole piece in an oven, and then pyrolyze the binder in the pole piece to obtain the lithium-ion battery positive electrode material waste. Powder (hybrid conductive carbon material).

[0092] Prepare a sulfuric acid solution with a mass percentage of 50%, add stoichiometric reducing agent ethylene glycol, measure 1010mL of acidic solution containing reducing agent in the container; weigh 500.0g of spent positive electrode material powder, and slowly add it to the above container Among them, the solid-to-liquid ratio is about 500g / L. Turn on the stirring and heat the reaction vessel with a water bath, the temperature of the water bath is 95°...

Embodiment 2

[0094] Take two unqualified lithium-ion secondary battery products in the production process, and the chemical formula of the positive electrode active material is LiNi 0.6 co 0.2 mn 0.2 o 2 . Disassemble the battery after immersing the battery in salt water, and dissolve the electrolyte remaining in the pole piece by solvent immersion, dry the pole piece in an oven, and then pyrolyze the binder in the pole piece to obtain the lithium-ion battery positive electrode material waste. Powder (hybrid conductive carbon material).

[0095] Weigh 100.0 g of powder and add it into the reaction vessel. A sulfuric acid solution with a mass percent content of 30% is prepared, and a reducing agent glycerol is added, and the reducing agent has a mass percent content of 5.0%. Slowly add the acidic solution containing the reducing agent into the above reaction vessel, the solid-to-liquid ratio is about 200g / L. At the same time, the stirring was started and the reaction vessel was heated...

Embodiment 3

[0097] Take 1kg of lithium-ion battery positive electrode material waste produced in the material production process, the chemical formula of the positive electrode active material is LiNi 0.5 co 0.2 mn 0.3 o 2 .

[0098] Prepare a sulfuric acid solution with a mass percentage of 50%, add the reducing agent 1,2-pentanediol, the reducing agent has a mass percentage of 10.0%, measure 1000mL of the acidic solution containing the reducing agent in the container; the solid-to-liquid ratio About 1000g / L. Turn on stirring and heat the reaction vessel with a water bath, the temperature of the water bath is 45° C., and cool down after 1 hour of reaction. Filtration to achieve solid-liquid separation to obtain leachate and filter residue respectively. Wash the filter residue several times, collect the washings and mix with the leachate. Take the liquid phase sample, analyze the concentration of nickel, cobalt, manganese and other metal elements by ICP-OES, calculate the leaching r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com