Liquid suction casting preparation method of sic fiber reinforced tial matrix composite

A composite material and fiber reinforced technology, which is applied in the field of liquid suction casting preparation of SiC fiber reinforced TiAl matrix composite materials, can solve the problems of poor flow, difficult, high melt viscosity, etc., to reduce production costs and avoid interface reactions. , the effect of fast alloy solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

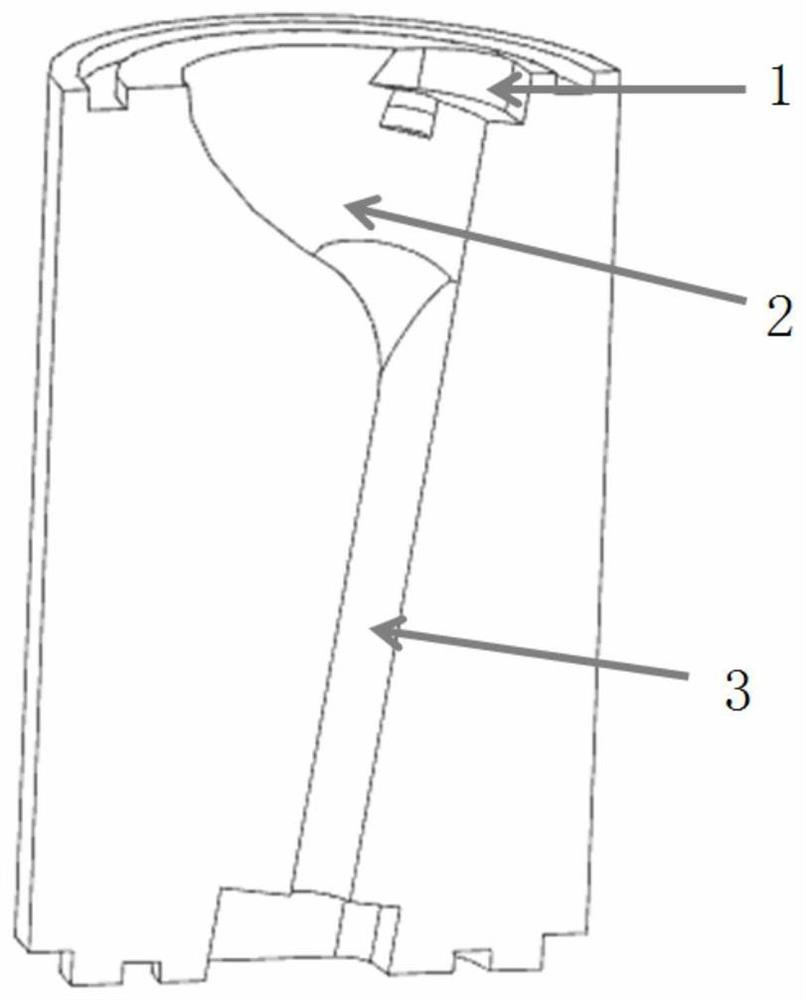

[0035] In this example, the selected matrix alloy composition is Ti-48Al-2Cr-2Nb, and the prepared composite material is a round rod with a diameter of 9 mm and a length of 90 mm, and a bundle of SiC fibers is added within the diameter of the center of the round rod within 1 mm.

[0036] (1) Non-consumable vacuum arc melting master alloy. Using Al-Nb master alloy, electrolytic Cr, Al sheet, and small particle sponge titanium as raw materials, calculate the required mass fraction of alloying elements according to the atomic percentage of the alloy composition, calculate the required mass of each alloying element, and prepare the alloy. Put the required raw materials into a water-cooled copper crucible in an electric arc furnace, and evacuate to 9.9×10 - 4 Pa, start smelting under the protection of inert gas Ar, and add electromagnetic stirring to smelt repeatedly 6 times to ensure that the composition of the alloy ingot is uniform.

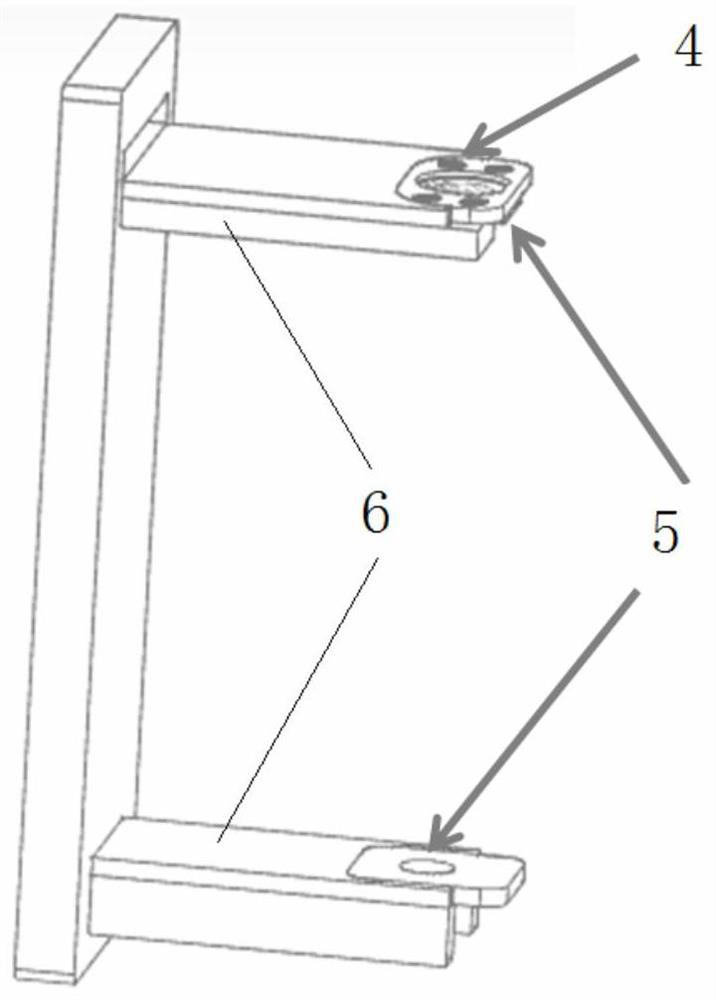

[0037] (2) Design of fiber volume fraction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com