Environment-friendly composite textile finishing agent and preparation method thereof

A textile finishing and environmentally friendly technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of destroying the beauty and practicability of textiles, poor textile combustion, physical health threats, etc., to achieve environmentally friendly industrial production, good durability. The effect of heat resistance, good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

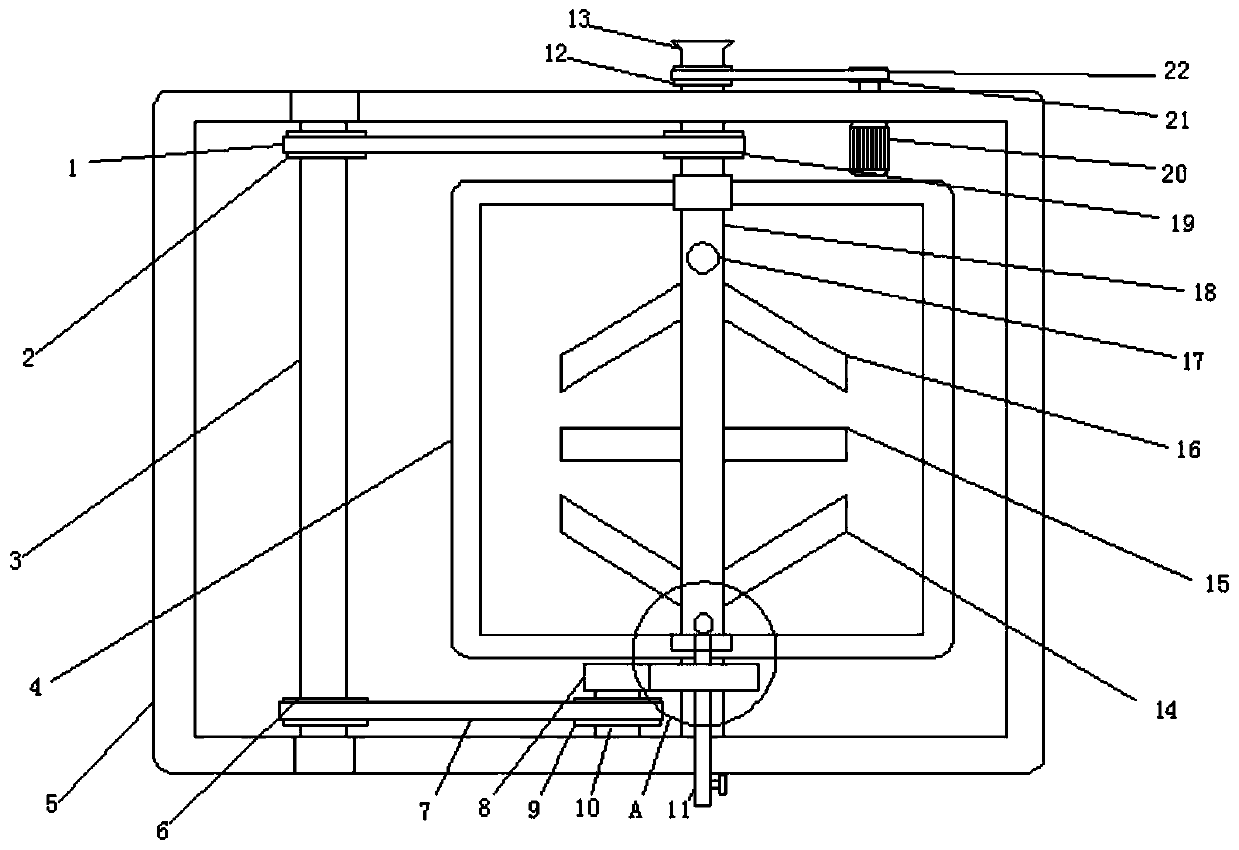

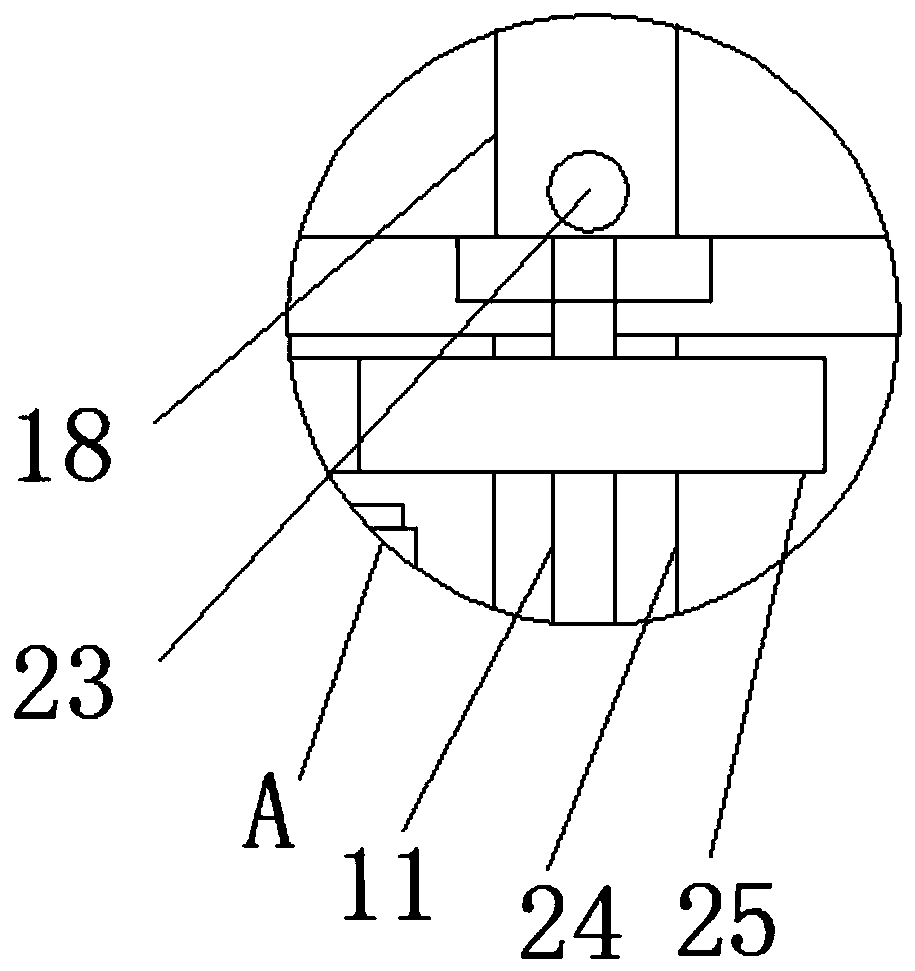

Image

Examples

Embodiment 1

[0040] An environment-friendly composite textile finishing agent, the finishing agent is prepared from the following raw materials, the parts by weight of each raw material are: 55 parts of octamethylcyclotetrasiloxane, N-β-aminoethyl-λ-aminopropyl methyl 68 parts of dimethoxysilane, 30 parts of gluconolactone, 15 parts of potassium hydroxide, 31 parts of λ-chloropropyl triethoxysilane, 20 parts of octadecyldimethylamine, 10 parts of isopropanol 6 parts of potassium iodide, 1.2 parts of 4-tert-butyl-4'-methoxydibenzoylmethane, 8 parts of modified polyoxyethylene fatty alcohol ether, 29 parts of 2,4-dimethylthiotoluenediamine , 26 parts of tribromophenyl glycidyl ether, 19 parts of polyoxypropylene glycol and 16 parts of 2,4-toluene diisocyanate.

[0041] The modified polyoxyethylene fatty alcohol ether is prepared through the following steps:

[0042] First add 20 parts of long-chain fatty alcohol, 7 parts of ethylene oxide, 8 parts of citric acid and 13 parts of sodium hydro...

Embodiment 2

[0052] An environment-friendly composite textile finishing agent, the finishing agent is prepared from the following raw materials, the parts by weight of each raw material are: 40 parts of octamethylcyclotetrasiloxane, N-β-aminoethyl-λ-aminopropyl methyl 60 parts of dimethoxysilane, 25 parts of gluconolactone, 13 parts of potassium hydroxide, 30 parts of λ-chloropropyl triethoxysilane, 20 parts of octadecyldimethylamine, 8 parts of isopropanol 5 parts of potassium iodide, 1 part of antioxidant, 7 parts of modified polyoxyethylene fatty alcohol ether, 25 parts of 2,4-dimethylthiotoluenediamine, 20 parts of tribromophenyl glycidyl ether, polyoxypropylene 15 parts of diol and 10 parts of 2,4-toluene diisocyanate.

[0053] The modified polyoxyethylene fatty alcohol ether is prepared through the following steps:

[0054] First add 30 parts of long-chain fatty alcohol, 15 parts of ethylene oxide, 16 parts of citric acid and 21 parts of sodium hydroxide into a 500mL reactor, then f...

Embodiment 3

[0064] An environment-friendly composite textile finishing agent, the finishing agent is prepared from the following raw materials, the parts by weight of each raw material are: 30 parts of octamethylcyclotetrasiloxane, N-β-aminoethyl-λ-aminopropyl methyl 40 parts of dimethoxysilane, 20 parts of gluconolactone, 10 parts of potassium hydroxide, 25 parts of λ-chloropropyl triethoxysilane, 17 parts of octadecyldimethylamine, 5 parts of isopropanol , 4 parts of potassium iodide, 0.8 parts of antioxidant, 5 parts of modified polyoxyethylene fatty alcohol ether, 15 parts of 2,4-dimethylthiotoluenediamine, 11 parts of tribromophenyl glycidyl ether, polyoxypropylene 8 parts diol and 7 parts 2,4-toluene diisocyanate.

[0065] The modified polyoxyethylene fatty alcohol ether is prepared through the following steps:

[0066] First add 25 parts of long-chain fatty alcohol, 10 parts of ethylene oxide, 15 parts of citric acid and 20 parts of sodium hydroxide into a 500mL reactor, then fill w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com