Treatment agent for formaldehyde wastewater

A formaldehyde wastewater and treatment agent technology, applied in the direction of adsorption water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of poor effect and stability, achieve small particle size, increase carboxyl Quantity, strengthen the effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

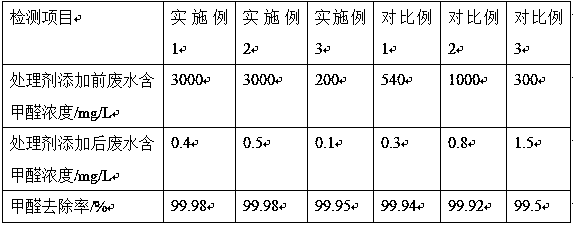

Examples

preparation example Construction

[0029] The preparation method of composite formaldehyde-removing base material comprises the steps:

[0030] (1) Take the coconut shell and crush it through a 80-mesh sieve in a pulverizer, collect the sieved particles and add 20% potassium hydroxide solution at a mass ratio of 1:12~18, mix evenly, and heat at 55~80°C for 1~3h , filter while it is hot, collect the filter residue and mix it with additives at a mass ratio of 10-15:1, spray and freeze with liquid nitrogen for 2-4 minutes, and then move to a culture room with a temperature of 55-70°C and a humidity of 55-70% to thaw. Take this as a freezing and thawing cycle, carry out 2~4 times, get the pretreated coconut shell, take the pretreated coconut shell and anhydrous ethanol according to the mass ratio of 1:12~20 and mix them in the ultrasonic oscillator, and use 50~60kHz ultrasonic vibration 10~16min, to get the dispersion mixture, according to the mass ratio of 1:4~8:15~25, take the additive, reagent A, and the dispers...

Embodiment 1

[0038] Reagent A: Mix potassium permanganate solution with a mass fraction of 12%, HCl solution with a concentration of 0.1mol / L, and pyridinium chlorochromate at a mass ratio of 1:3:0.03 to obtain reagent A.

[0039] Reagent B: At 35°C, mix N-methylimidazole and allyl chloride in a reaction kettle at a mass ratio of 1:4, protect with nitrogen, stir at 500r / min for 1h, and rotary evaporate at 45°C to 25% of the original volume. %, to obtain reagent B.

[0040] Auxiliary: Mix microcrystalline cellulose and magnesium stearate at a mass ratio of 1:2 to obtain the adjuvant.

[0041] Interface auxiliary material: at 55°C, mix citric acid solution with a mass fraction of 20% and aluminum chloride in a reaction kettle at a mass ratio of 6:1, stir magnetically at 500r / min for 45min, and add 16% of the mass of citric acid solution Mix the fraction with 10% sodium aluminate solution, raise the temperature to 90°C and keep it under reflux for 1 hour to obtain the reaction solution. Take...

Embodiment 2

[0054] Reagent A: Mix potassium permanganate solution with a mass fraction of 12%, HCl solution with a concentration of 0.1mol / L, and pyridinium chlorochromate at a mass ratio of 1:7:0.03 to obtain reagent A.

[0055] Reagent B: At 45°C, N-methylimidazole and allyl chloride were mixed in a reaction kettle at a mass ratio of 1:8, protected by nitrogen gas, stirred at 800r / min for 3h, and rotary evaporated at 60°C to 40% of the original volume. %, to obtain reagent B.

[0056] Auxiliary: Mix microcrystalline cellulose and magnesium stearate at a mass ratio of 1:5 to obtain the adjuvant.

[0057] Interface auxiliary material: at 75°C, mix citric acid solution with a mass fraction of 20% and aluminum chloride in a reaction kettle at a mass ratio of 10:1, stir magnetically at 800r / min for 65min, add 25% of the mass of citric acid solution The fraction is 10% sodium aluminate solution and mixed, the temperature is raised to 100 ° C and refluxed for 3 hours to obtain the reaction so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com