Magnetic silica filler, magnetic affinity filler and preparation method and application of magnetic affinity filler

A silicon dioxide and magnetic technology, which is applied in the field of magnetic affinity filler and its preparation, can solve the problems of uncontrollable particle size and pore size, easy disappearance of magnetism, and high temperature resistance, etc., and achieves a simple introduction method, not easy to demagnetize, and not easy to leak Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention provides a kind of preparation method of magnetic silicon dioxide filler, and this method comprises the following steps:

[0042] Sulfonate the porous polymer microspheres;

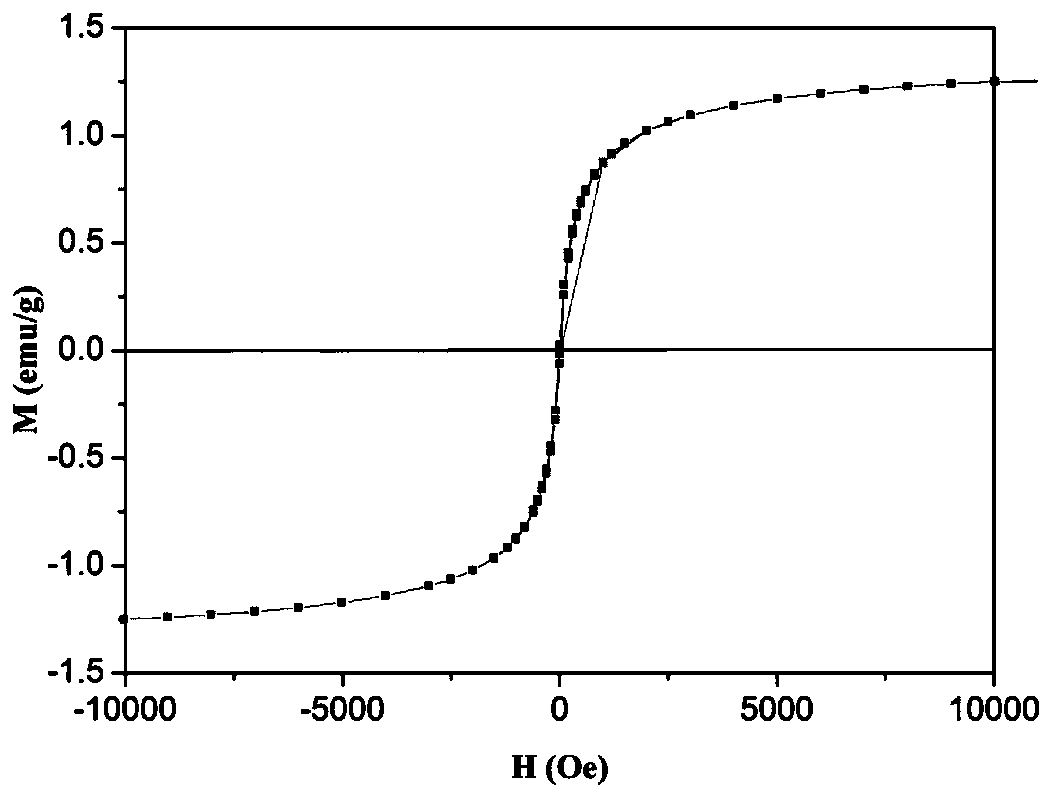

[0043] Combining sulfonated porous polymer microspheres with Fe 3+ and Fe 2+ The iron source contacts to adsorb Fe 3+ and Fe 2 + , the Fe in this iron source 3+ :Fe 2+ Molar ratio = 2:1, add ammonia water after the adsorption is completed, and generate magnetic Fe in situ 3 o 4 / polymer microspheres;

[0044] A silicon source is added to the magnetic Fe 3 o 4 In the polymer microspheres, the sol-gel reaction is carried out to obtain the magnetic Fe 3 o 4 / High molecular polymer / silica composite microspheres;

[0045] The magnetic Fe 3 o 4 / Magnetic Fe in High Molecular Polymer / Silica Composite Microspheres 3 o 4 In situ oxidation to γ-Fe 2 o 3 , get γ-Fe 2 o 3 / High molecular polymer / silica composite microspheres;

[0046] The γ-Fe 2 o 3 The high-molec...

Embodiment 1

[0055] Embodiment 1: Preparation of magnetic silica filler

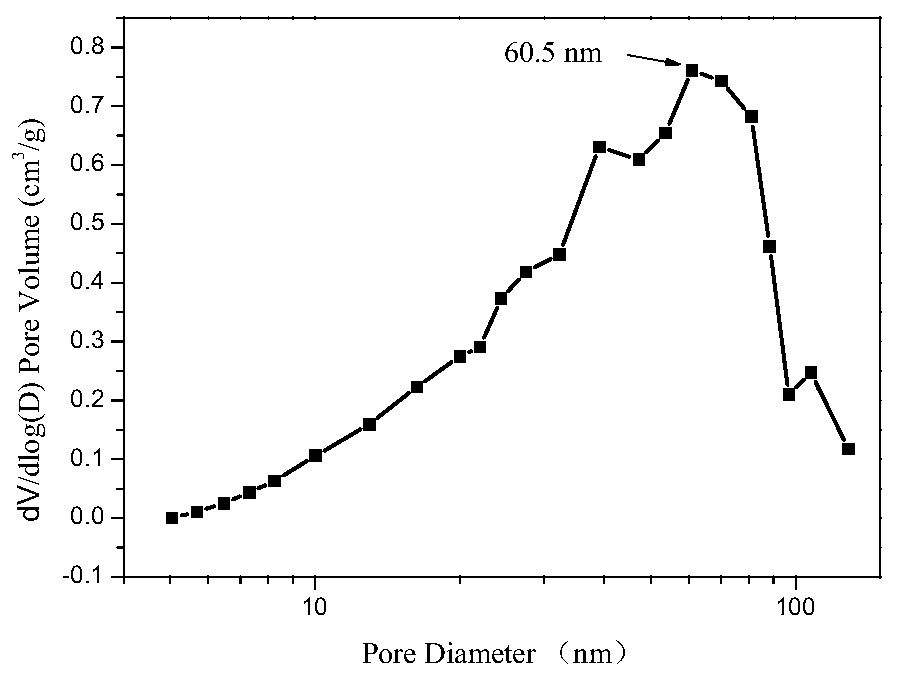

[0056] Weigh 20 g of magnetic silica filler polyglycidyl methacrylate / ethylene glycol dimethacrylate (PGMA / EGDMA) microspheres with a particle size of 7.42 μm, ultrasonically disperse them in 500 ml of water, add 20 g of sodium sulfite, and dissolve them at 160 rpm The reaction was mechanically stirred for 24h. After the reaction, filter with suction, wash with water and ethanol three times respectively to obtain sulfonated porous PGMA / EGDMA microspheres, and dry them in an oven at 50°C for future use.

[0057] Weigh 1.645g FeCl 2 4H 2 O and 4.34 g FeCl 3 ·6H 2 O was dissolved in 20ml of water, and vacuumized to prepare Fe 2+ :Fe 3+ Iron source solution with a molar ratio of 1:2, N 2 Save it for future use. Ultrasonic disperse 0.5 g of the sulfonated 7.42 μm porous PGMA / EGDMA microspheres prepared above in 20 ml of water, add 0.5 ml of the prepared iron source solution, and after 12 hours of adsorption, direc...

Embodiment 2

[0062] Embodiment 2: Preparation of magnetic silica filler

[0063]Weigh 20g of magnetic silica filler polystyrene / divinylbenzene (PS / DVB) microspheres with a particle size of 4.54μm, ultrasonically disperse them in 500ml of water, add 20g of sodium sulfite, and react with mechanical stirring at 160rpm for 24h. After the reaction, filter with suction, wash with water and ethanol three times respectively to obtain sulfonated porous PS / DVB microspheres, and dry them in an oven at 50°C for future use.

[0064] Weigh 1.645g FeCl 2 4H 2 O and 4.34 g FeCl 3 ·6H 2 O was dissolved in 20ml of water, and vacuumized to prepare Fe 2+ :Fe 3+ Iron source solution with a molar ratio of 1:2, N 2 Save it for future use. Ultrasonic disperse 0.5 g of the sulfonated 4.54 μm porous PS / DVB microspheres prepared above in 20 ml of water, add 0.125 ml of the prepared iron source solution, and after 12 hours of adsorption, directly add 1 ml of 28% by weight ammonia water to the solution, Stir m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com