Process and device for preparing nano-scale core-shell structured carbon-coated composite material

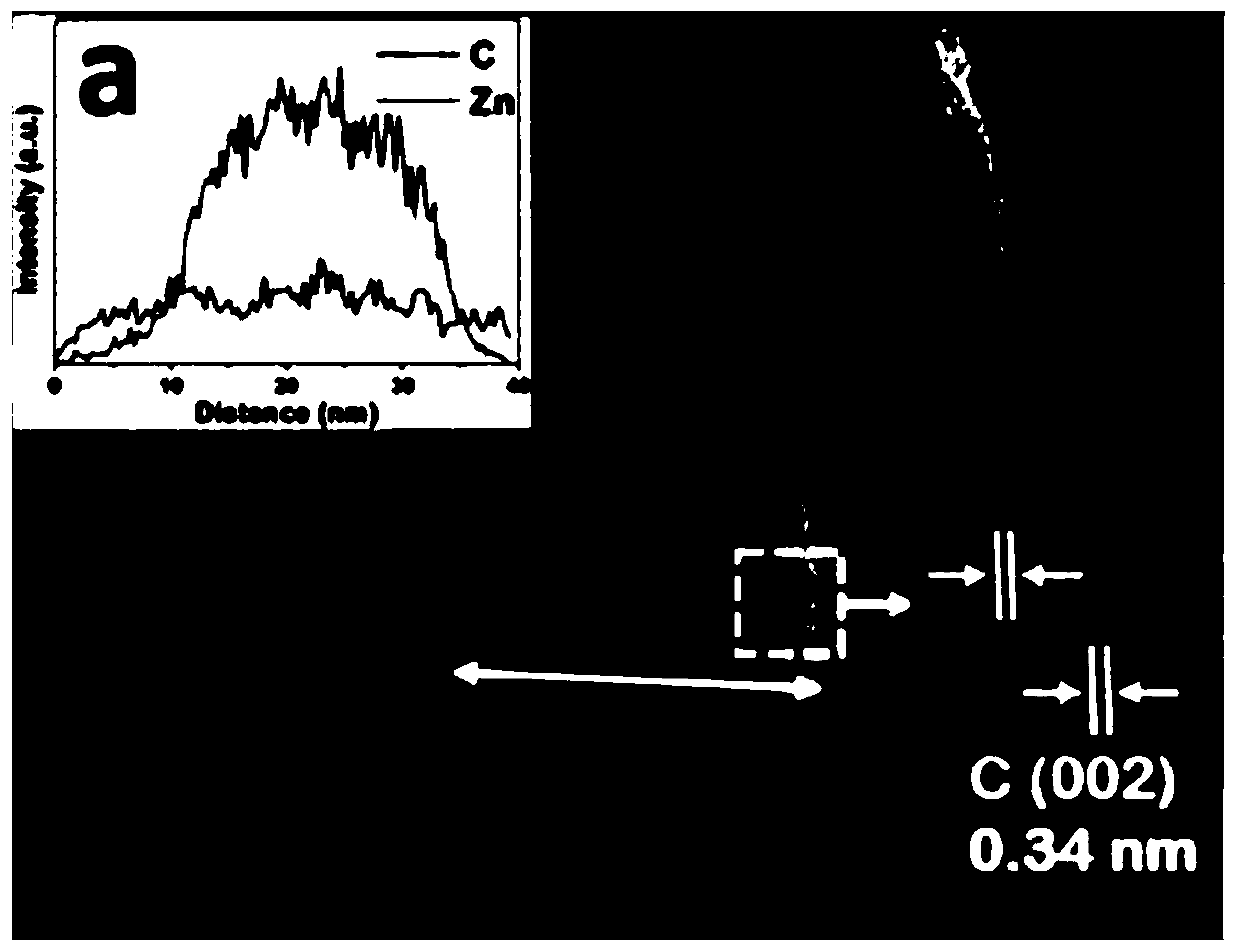

A composite material, core-shell structure technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of unreachable, poor controllability, low yield of nanomaterials, etc., to achieve uniform and smooth thickness, expandable area, thickness uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

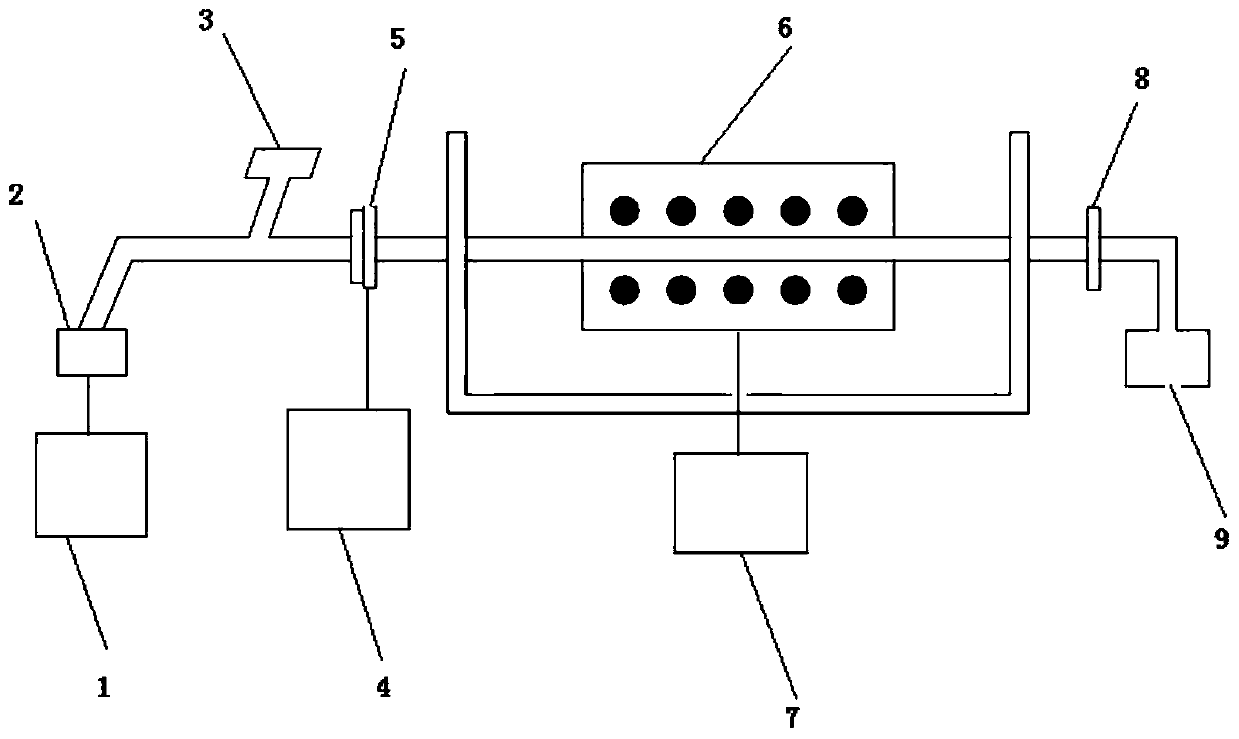

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Preparation of carbon precursor: Styrene and acetone were selected as raw materials (both with a purity of 99.99%), and the carbon precursor was prepared according to the volume ratio of the two as acetone:styrene=4:1, and mixed by ultrasonic vibration.

[0033] Step 2: Take a certain amount of CeO nanoparticles (particle size <100nm) and add them to ethanol (99.99% pure), stir magnetically for 1 hour, then perform ultrasonic dispersion for 30 minutes, and place the resulting suspension in a vacuum oven at 80°C to obtain The dry powder was ground with a quartz mortar and transferred to a quartz tube of a rotary vapor deposition system.

[0034] Step 3: Before the entire reaction starts, it is necessary to use argon gas to remove the air in the furnace, and set the parameters of the reaction system. The flow rate of argon gas is 100ml / min; the precursor liquid of step 1 carbon is continuously injected at 2ml within 15-60min of system operation. / h flow rate into ...

Embodiment 2

[0037] Step 1: Preparation of carbon precursor: Styrene and acetone were selected as raw materials (both with a purity of 99.99%), and the carbon precursor was prepared according to the volume ratio of the two as acetone:styrene=4:1, and mixed by ultrasonic vibration.

[0038] Step 2: Take a certain amount of CrO nanoparticles (particle size <100nm) and add them to ethanol (99.99% pure), stir magnetically for 1 hour, then disperse with ultrasonic waves for 30 minutes, and place the resulting suspension in a vacuum oven at 80°C to obtain The dry powder was ground with a quartz mortar and transferred to a quartz tube of a rotary vapor deposition system.

[0039] Step 3: Before the entire reaction starts, it is necessary to use argon gas to remove the air in the furnace, and set the parameters of the reaction system. The flow rate of argon gas is 100ml / min; the precursor liquid of step 1 carbon is continuously injected at 2ml within 15-60min of system operation. / h flow rate into...

Embodiment 3

[0042] Step 1: Preparation of carbon precursor: Styrene and acetone were selected as raw materials (both with a purity of 99.99%), and the carbon precursor was prepared according to the volume ratio of the two as acetone:styrene=4:1, and mixed by ultrasonic vibration.

[0043] Step 2: Take a certain amount of ZrO nanoparticles (particle size <100nm) and add them to ethanol (99.99% pure), stir magnetically for 1 hour, then perform ultrasonic dispersion for 30 minutes, and place the resulting suspension in a vacuum oven at 80°C to obtain The dry powder was ground with a quartz mortar and transferred to a quartz tube of a rotary vapor deposition system.

[0044] Step 3: Before the entire reaction starts, it is necessary to use argon gas to remove the air in the furnace, and set the parameters of the reaction system. The flow rate of argon gas is 100ml / min; the precursor liquid of step 1 carbon is continuously injected at 2ml within 15-60min of system operation. / h flow rate into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com