TNT/CdS/TiO2/Pt core-shell structure nanotube and preparation method thereof

A core-shell structure and nanotube technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as structure and recombination position confusion, complex electron transfer paths, and reduced quantum efficiency. Achieve the effect of short electron transmission distance, improve photocatalytic activity and stability, and less recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Titanate nanotubes (titanate nanotubes, TNT) preparation: 2.5g commercial TiO 2 Add to 125ml NaOH (10M) aqueous solution, stir for 2 hours, pour into the reaction kettle, react in an oven at 150°C for 4 days, then wash with deionized water, then add the sample to 250ml 0.1M HCL and stir for 2 hours, then Suction-filtered and washed with deionized water, the obtained sample was dried in an oven at 110°C for 24 hours. Then the dried sample was heat-treated at 600° C. for 4 hours to obtain titanate nanotubes (TNT).

[0035] (2) Preparation of CdS quantum dots: Heat 30ml of CdO, 1-octadecene and oleic acid mixture with a concentration of 0.4M to 320°C under the protection of an inert gas, and then add 3ml of tri-n-octyl dissolved in sulfur powder Phosphorus (concentration of S is 4M), keep the temperature at 280°C for 5 minutes. Then the cooled product was dissolved with n-hexane and methanol, then precipitated with acetone, centrifuged at 5000r / min for 5min, and puri...

Embodiment 2~5

[0040] The preparation method of embodiment 2~5 is identical with embodiment 1, just carries out TiO in step (4). 2 The number of cycles during atomic layer deposition was changed from 80 to 10, 20, 40, and 60, respectively.

[0041] The test results of the materials obtained in the above examples are specifically as follows.

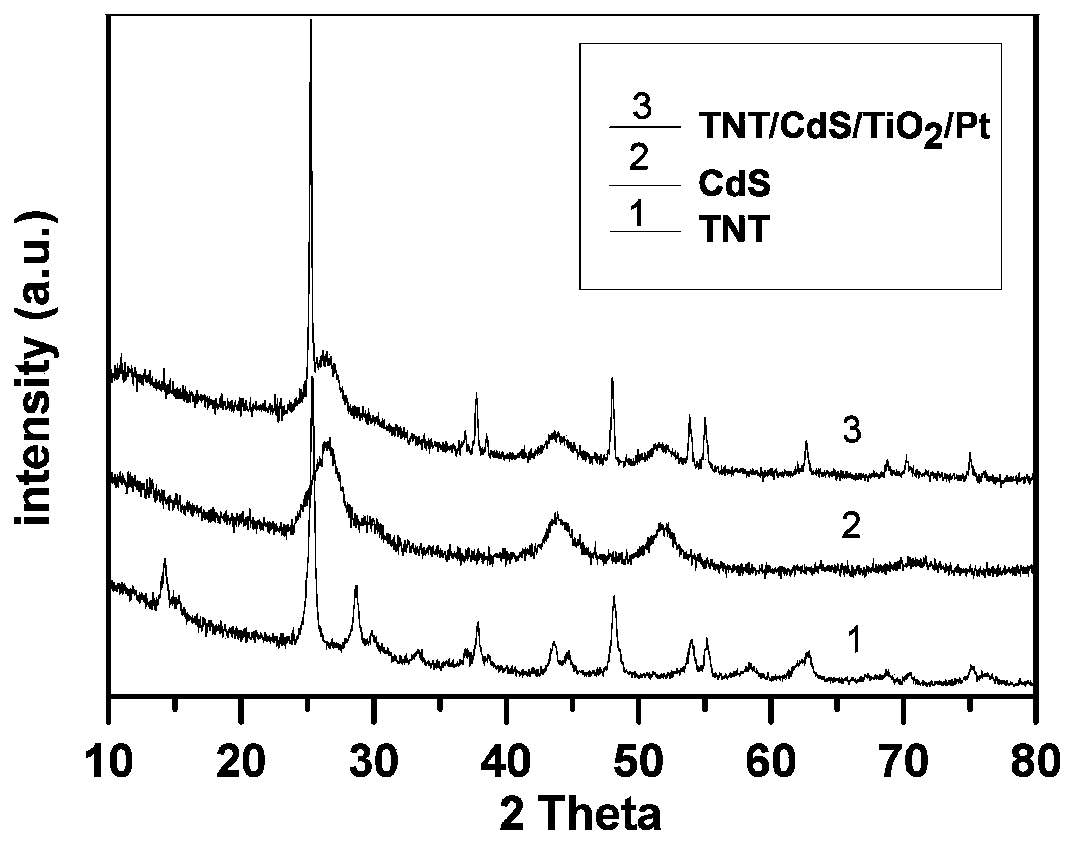

[0042] (1) X-ray diffraction analysis (XRD)

[0043] figure 1 Titanate nanotubes (TNT), CdS quantum dots and TNT / CdS / TiO prepared for Example 1 2 XRD patterns of / Pt core-shell nanotubes. from figure 1 It can be seen that the prepared TNT / CdS / TiO 2 The XRD of / Pt core-shell nanotubes has the characteristic peaks of TNT and CdS at the same time, which proves that TNT and CdS are successfully combined.

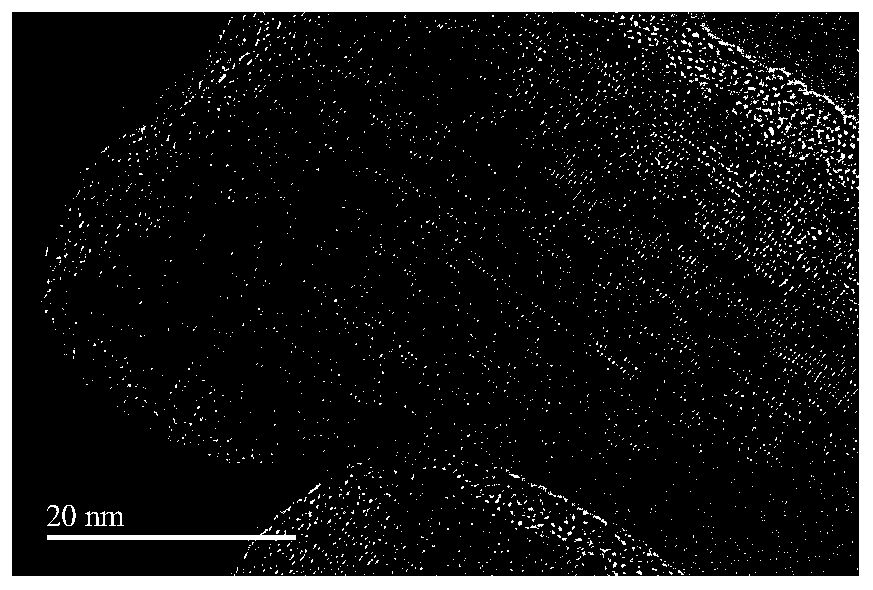

[0044] (2) Transmission electron microscope analysis (TEM)

[0045] figure 2 For the TNT / CdS / TiO prepared in Example 1 2 / TEM image of Pt core-shell nanotubes.

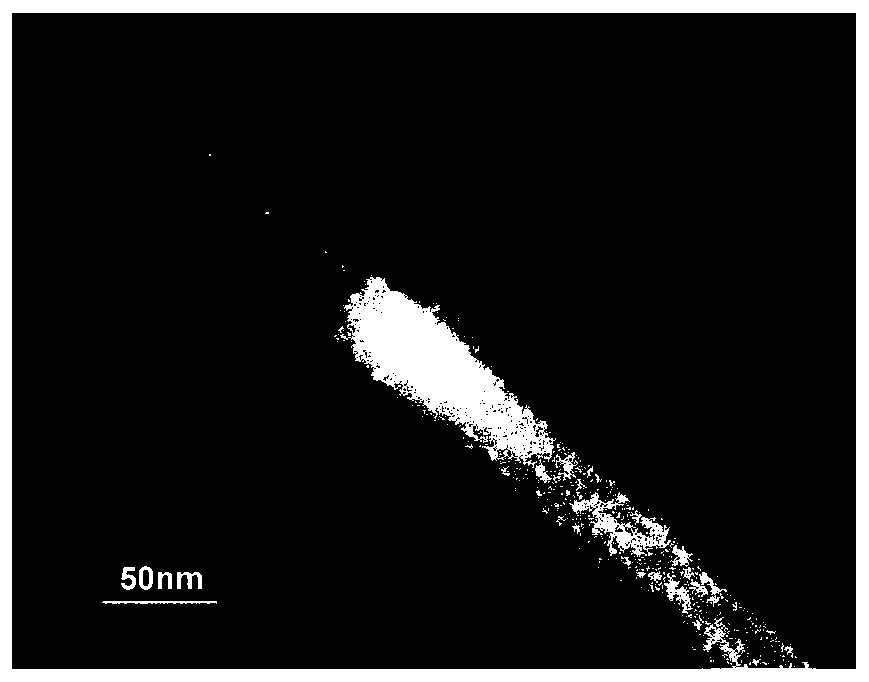

[0046] (3) High Angle Annular Dark Field Image (HAADF-STEM)

[0047] image 3 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com