Non-lead perovskite photoelectric functional material, solar cell and preparation method and application of non-lead perovskite photoelectric functional material

A technology for optoelectronic functional materials and solar cells, which is applied in the fields of luminescent materials, photovoltaic power generation, amino compound preparation, etc., can solve problems such as environmental and human and animal health threats, environmental pollution, and solar cell photoelectric conversion efficiency attenuation, etc. Effects of protection, good solubility, excellent humidity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0040] The present invention provides a non-lead perovskite photoelectric functional material whose chemical formula is ABX 4 .

[0041] where A is C 6 H 5 NH 3 + , C 6 H 5 CH 2 NH 3 + , C 6 H 5 CH 2 CH 2 NH 3 + At least one of; B is a trivalent metal ion; X is a halogen ion. Trivalent metal ions can be selected from Bi 3+ , Sb 3+ at least one of them. X can be selected from F - , Cl - , Br - , I - at least one of them.

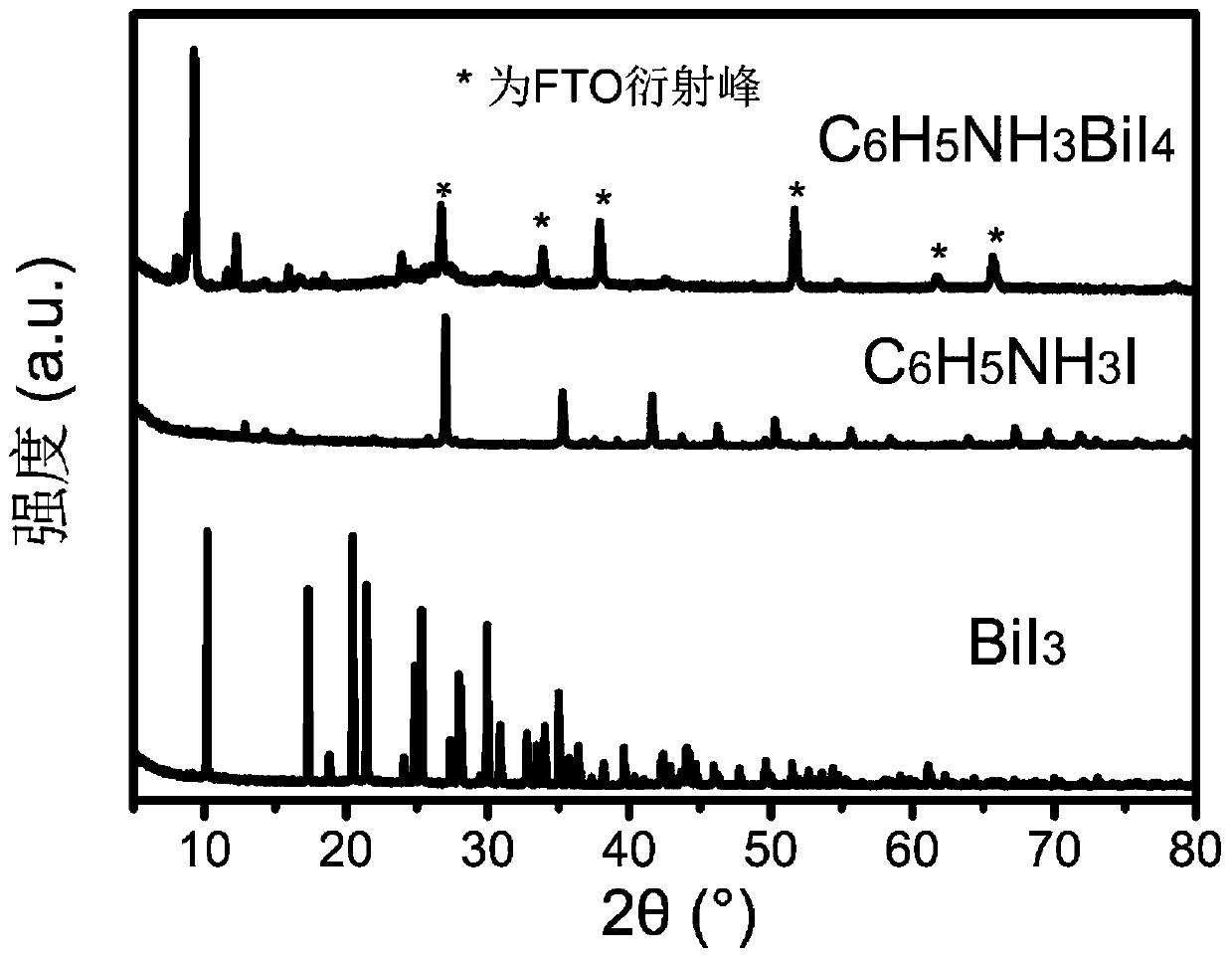

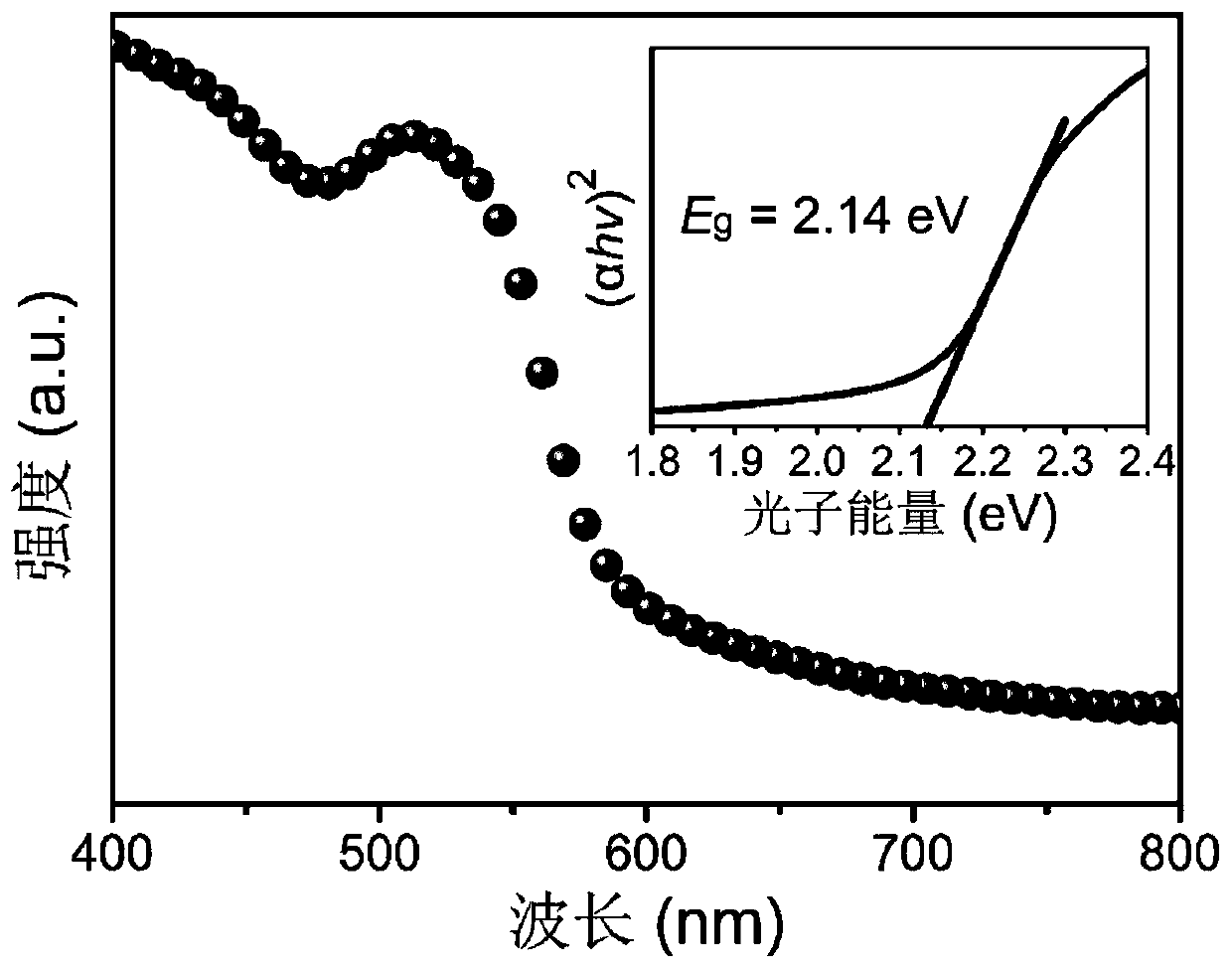

[0042] Preferred C in the present invention 6 H 5 NH 3 BiX 4 is a one-dimensional perovskite composed of one-dimensional BiX 6 Octahedral co-edge chain and hydrophobic C 6 H 5 NH 3 + composition, has excellent humidity stability, and its XRD pattern is as follows figure 2 shown.

[0043] An ABX of the present invention 4 The preparation method of the light absorption layer film comprises the following steps:

[0044] 1) Preparation of precursor solution: Weigh equimolar amounts of halogen source and hydrophobic phenyl catio...

Embodiment 1

[0049] Embodiment 1, the preparation of solar cell:

[0050] (1) Pretreatment of FTO transparent conductive glass: The etched FTO transparent conductive glass was ultrasonically cleaned with acetone, ethanol, and deionized water for 15 minutes, dried with nitrogen, and then treated with an ultraviolet ozone cleaner for 30 minutes to remove residual organic matter ;

[0051] (2) Preparation of titanium oxide dense layer: A titanium oxide dense layer was prepared on the pretreated FTO transparent conductive glass by spin coating (the process parameters were 2500r.p.m, 20s), and annealed at 500 °C (the heating rate was 5℃ / min, holding time is 30min);

[0052] (3) Preparation of titanium oxide mesoporous layer: spin-coat the titanium oxide mesoporous slurry on the titanium oxide dense layer (the process parameters are 2500r.p.m, 60s), and anneal at 500 °C (the heating rate is 5 °C / min, the holding time is 30min);

[0053] (4) Preparation of methylamine halide copper-based pero...

Embodiment 2

[0056] Embodiment 2, the preparation of solar cell:

[0057] (1) FTO transparent conductive glass pretreatment: same as Example 1;

[0058] (2) Preparation of titanium oxide dense layer: the same as in Example 1;

[0059] (3) Preparation of titanium oxide mesoporous layer: the same as in Example 1;

[0060] (4) Preparation of methylamine halide copper-based perovskite light-absorbing layer: C with a molar concentration of 0.5 M was placed on the titanium oxide mesoporous layer. 6 H 5 NH 3 BiI 4 The precursor solution (anhydrous ethanol as the solvent) was used to prepare the non-lead perovskite light-absorbing layer by spin coating-vacuum pumping method (the process parameters were 4000r.p.m, 3s, and the air pressure in the pumping chamber: 1000Pa), and was heated at 75°C on a hot stage. After heating for 30min, red C is formed after heating 6 H 5 NH 3 BiI 4 perovskite thin films;

[0061] (5) Preparation of hole transport layer: An inorganic hole transport layer CuP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com