A kind of au@cu2-δx nanocrystal, its preparation method and application

A nanocrystal and volumetric technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low sulfide absorption, lower light-to-heat conversion efficiency, etc., and achieve the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

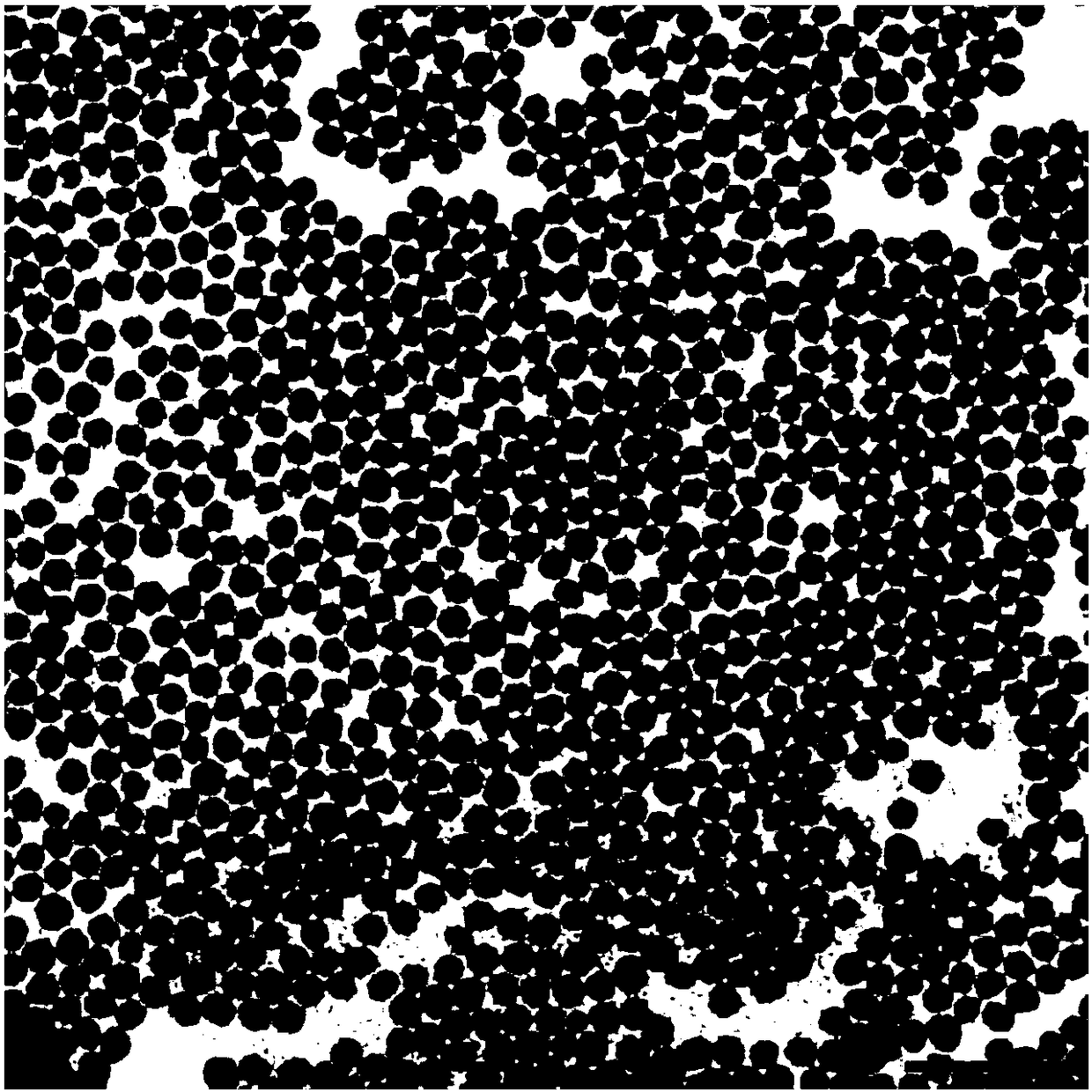

[0063] 1. Preparation of granular Au@CdS nanocrystals

[0064] (1) Stir 0.72mL of oleic acid, 1mL of 1mol / L sodium hydroxide solution, 4mL of acetonitrile and 4mL of water at room temperature, then add chloroauric acid (HAuCl 4 4H 2 (2) 20 mg, stirred to form a uniform transparent microemulsion, added 80 μL of 0.1mol / L ascorbic acid solution and 13 mL of cyclohexane, and continued to stir for 6 h, left to stand, after layering, take the organic layer liquid; add ethanol to the organic layer liquid 39mL, and centrifuged at 2000rpm for 7min to obtain 4nm granular Au nanocrystals;

[0065] (2) Disperse the granular Au nanocrystals in 20mL of toluene to obtain the granular Au nanocrystal sol, the concentration is 1mg / mL, take 8mL of the granular Au nanocrystal sol, add 0.2mL of oleylamine, 10mg / mL silver nitrate methanol After the solution was 1 mL, it was sealed in a 20 mL capacity screw bottle, heated to 60°C in an oil bath, and kept at a constant temperature for 16 hours to o...

Embodiment 2

[0079] 1. Preparation of granular Au@CdS nanocrystals

[0080] (1) At room temperature, stir 0.72mL of oleic acid, 1mL of 1mol / L sodium hydroxide solution, 4mL of acetonitrile and 4mL of water evenly, then add 20mg of chloroauric acid and stir to form a uniform transparent microemulsion, add 0.1mol / L 80μL of ascorbic acid solution and 13mL of cyclohexane, and continue to stir for 6h, add 4mg of chloroauric acid, 40μL of 0.1mol / L ascorbic acid solution, continue to stir for 3h; stand still, take the organic layer liquid after layering; add to the organic layer liquid 39 mL of absolute ethanol, and centrifuged at 2000 rpm for 7 min to obtain 5 nm granular Au nanocrystals;

[0081] (2) Disperse the granular Au nanocrystals in 40mL of toluene to obtain the granular Au nanocrystal sol, the concentration is 1mg / mL, take 8mL of the granular Au nanocrystal sol, add 0.2mL of oleylamine, 10mg / mL silver nitrate methanol After 1mL of the solution was sealed in a 20mL screw bottle, the oi...

Embodiment 3

[0095] 1. Preparation of granular Au@CdS nanocrystals

[0096] (1) At room temperature, stir 0.72mL of oleic acid, 1mL of 1mol / L sodium hydroxide solution, 4mL of acetonitrile and 4mL of water evenly, then add 30mg of chloroauric acid and stir to form a uniform transparent microemulsion, add 0.1mol / L 80 μL of ascorbic acid solution and 13 mL of cyclohexane, and continue to stir for 6 hours, add 8 mg of chloroauric acid, 40 μL of 0.1 mol / L ascorbic acid solution, continue to stir for 3 hours, stand still, take the organic layer liquid after layering; add to the organic layer liquid Ethanol 39mL, and with 2000rpm centrifugal 7min, obtain the granular Au nanocrystal of 8nm;

[0097] (2) Disperse the granular Au nanocrystals in 30mL of toluene to obtain the granular Au nanocrystal sol, the concentration is 1mg / mL, take 8mL of the granular Au nanocrystal sol, add 0.2mL of oleylamine, 10mg / mL silver nitrate methanol After 1mL of the solution was sealed in a 20mL screw bottle, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com