High-rate long-cycle performance multi-element composite positive electrode material and preparation method thereof

A cathode material and multi-component composite technology, which is applied in the field of high-rate and long-cycle performance multi-component composite cathode materials and their preparation, and can solve the problems of deterioration, fragile cycle performance, and shortening of lithium ion transmission paths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

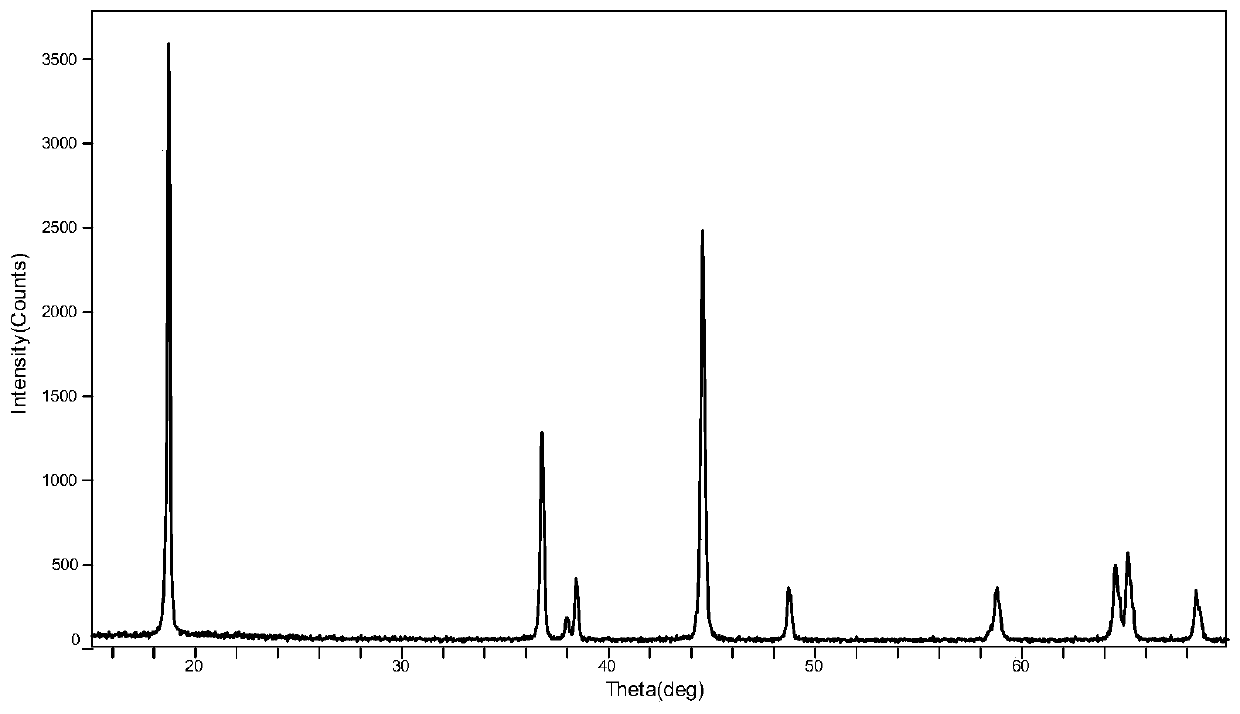

Embodiment 1

[0035] Select spherical graphite with a D50 of 0.5 microns and add it to the reactor for high-speed dispersion for 20 minutes, then make a mixed solution of nickel sulfate, cobalt sulfate and manganese sulfate according to the Ni:Co:Mn molar ratio of 0.6:0.2:0.2 and mix evenly. Ni, The total number of moles of the three transition metal ions of Co and Mn is 2mol / L, and then 6mol / L of NaOH solution and transition metal ion solution and 6mol / L of ammonia are added to the reaction vessel at the same time, and the pH of the reaction system is controlled to be 11.5, the reaction temperature is 60°C. Then the obtained precipitate was filtered, washed, and dried at 110°C for 10 hours to obtain a C core Ni0.6Co0.2Mn0.2(OH)2 precursor. Lithium hydroxide and C core Ni0.6Co0.2Mn0.2(OH)2 are added with 0.1wt% Nb2O5 (as Nb Mix with the mass ratio of the precursor), mix evenly in a high-speed mixer, raise the temperature to 650°C at a heating rate of 3°C / min, keep it for 2h, then heat up t...

Embodiment 2

[0038] Based on the LiNi0.6Co0.2Mn0.2O2 matrix material with 0.1% Nb-doped hollow prepared in Example 1, 1000mL H2O was added to the stirring tank, 2000g of the above-mentioned sieved material was added, and after 30°C constant temperature for 10min, 56g of nano The alumina dispersion was stirred at a constant temperature of 30°C for 1 hour, and then vacuum-dried with a rotary evaporator. The dried material was put into a high-temperature furnace, sintered at 700°C for 10 hours, and then passed through a 325-mesh sieve. Finally, the Al coating amount was 0.15% uniformly coated LiNi0.6Co0.2Mn0.2O2 multi-element composite cathode material of the hollow doped Nb, other is the same as embodiment 1

Embodiment 3

[0040] Except replacing Nb2O5 with Ta2O5, others are the same as in Example 1, and a tantalum-doped LiNi0.6Co0.2Mn0.2O2 composite cathode material with a uniform hollow structure is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com