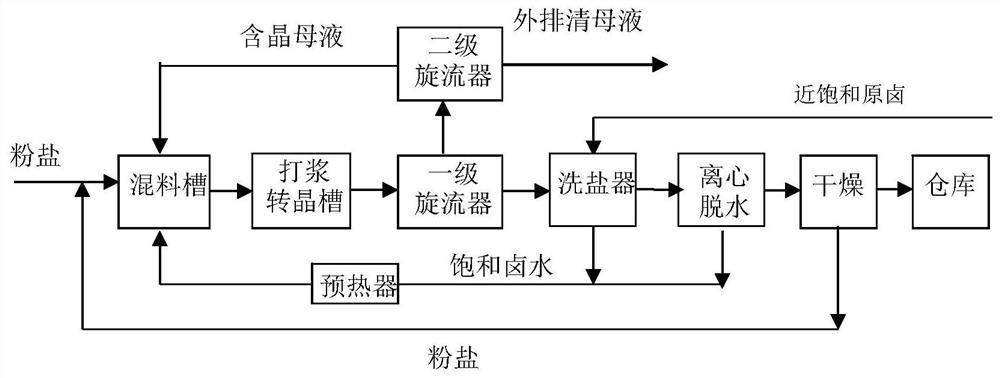

A process for producing genuine salt products by transferring powder salt to crystals

A process and crystal transformation technology, which is applied in the shape preparation of alkali metal halides, etc., can solve the problems of secondary evaporation crystallization and evaporation equipment, long production process, occupation of genuine industrial salt market, etc., and achieve low dissolution rate , Good effect of crystal transformation, and the effect of increasing the crystal growth temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

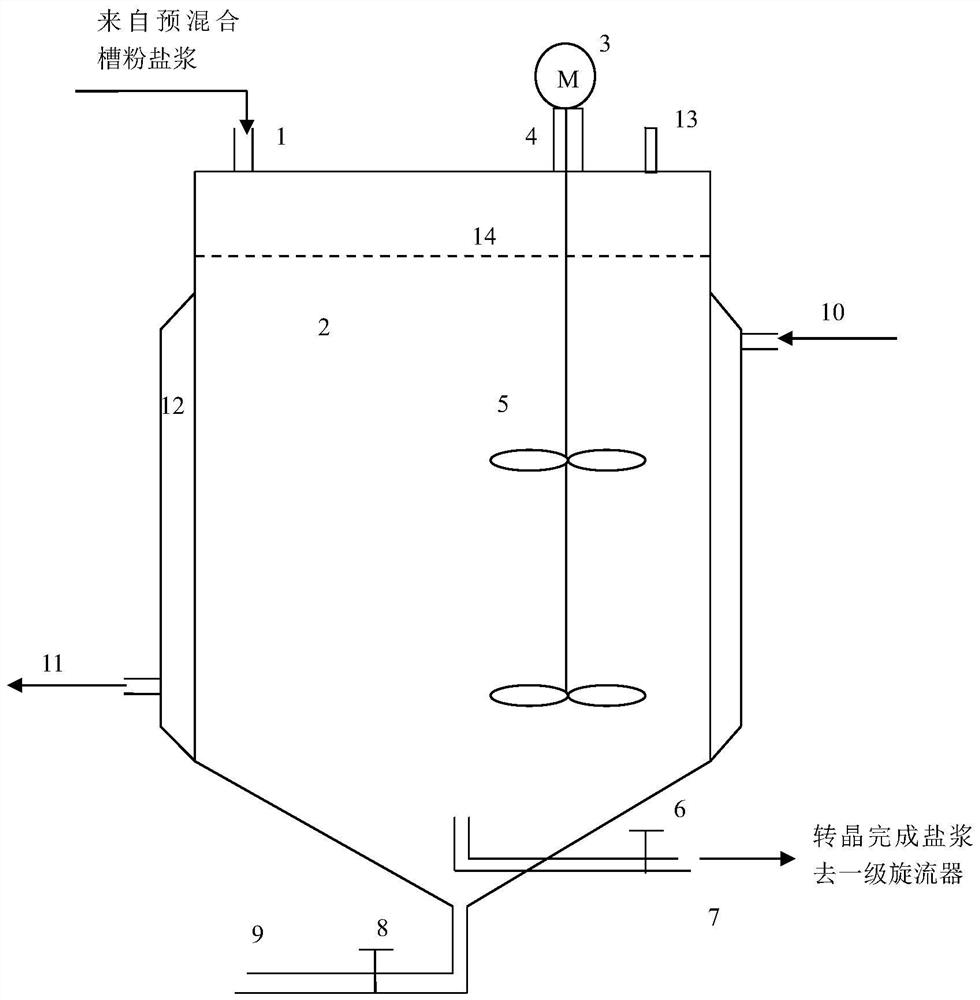

Method used

Image

Examples

Embodiment 1

[0042] A powder salt, particle size distribution: 5% of 80-mesh sieve, 15% of 80-100 mesh sieve, 80% of 100-mesh sieve. Through the method of the present invention, powdery sodium chloride is crystal-transformed and industrial salt process method is crystal-transformed. Saturated original halogen is used as the crystal transformation system solution, saturated brine (containing about 305g / L NaCl, NaSO 4 About 14g / L) after salt washing, go to the mixing tank and mix with powder salt to make salt slurry (solid-liquid volume ratio 30%), and the uniformly mixed salt slurry enters the beating and crystal conversion tank, the speed is 100 rpm, and the solid-liquid ratio is controlled 30%, crystal cultivation for 10 hours, the temperature of the mother liquor in the system is 85°C, and the salt slurry is separated by the first-stage cyclone. , the underflow crystal-containing mother liquor is sent to the feeding and mixing process for circulation, and the concentrated salt slurry se...

Embodiment 2

[0044] A kind of powder salt, particle size distribution: 5% of 80-mesh sieve, 15% of 80-100 mesh sieve, 80% of 100-mesh sieve, through the powdery sodium chloride crystal conversion industrial salt process method of the present invention. . After preheating to 90°C, saturated original halogen (containing about 295g / L NaCl, NaSO 4About 18g / L) is used as the crystal transformation system solution. After the saturated brine is washed with salt, go to the mixing tank and mix with powder salt to make salt slurry (solid-to-liquid ratio 10%). / min, the solid-liquid ratio is controlled at 10%, the crystal is cultivated for 16 hours, the temperature of the mother liquor in the system is 70°C, the salt slurry is separated through the first-stage cyclone, and the mother liquor and fine crystals are returned to the second-stage cyclone to continue separation, and the second-stage cyclone Most of the clear night is discharged from the top flow, and the crystal-containing mother liquor in...

Embodiment 3

[0046] A kind of powder salt, particle size distribution: 10% of the 100-mesh sieve, 90% of the 100-mesh sieve; through the powdery sodium chloride crystal conversion industrial salt process method of the present invention, the crystal conversion treatment. After preheating at 95°C, saturated original halogen (containing about 295g / L NaCl, NaSO 4 About 18g / L) is used as the crystal transformation system solution. After the saturated brine is washed with salt, go to the mixing tank and mix with powder salt to make salt slurry (solid-to-liquid ratio 10%). / min, the solid-liquid ratio is controlled at 10%, the crystal is cultivated for 16 hours, the temperature of the mother liquor in the system is 70°C, the salt slurry is separated through the first-stage cyclone, and the mother liquor and fine crystals are returned to the second-stage cyclone to continue separation, and the second-stage cyclone Most of the clear night is discharged from the top flow, and the crystal-containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com