Preparation method of p-phenylenediamine

A technology of p-phenylenediamine and p-dichlorobenzene, which is applied in the field of synthesis of p-phenylenediamine, can solve the problems of low atom utilization rate, cumbersome synthesis of raw materials, increased equipment investment, etc., and achieves low cost, easy separation and recovery, The effect of long catalyst life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

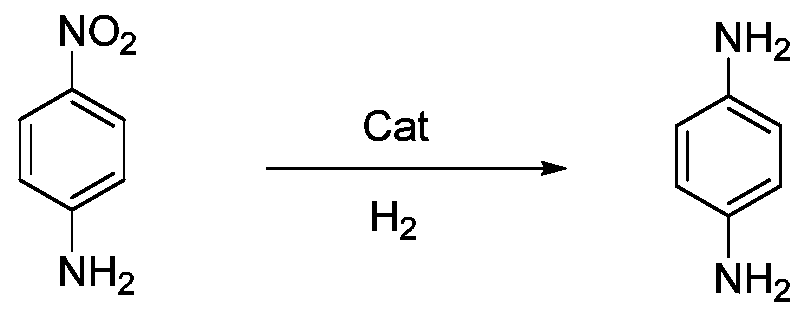

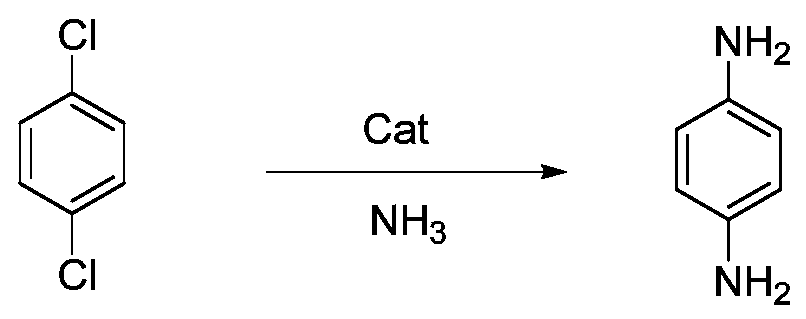

Method used

Image

Examples

Embodiment 1

[0019] Add 117.72g p-dichlorobenzene (99.9%, 0.8mol) in 1L autoclave, 437.14g ammoniacal liquor (35%, 9.0mol), 19.16g copper ferrite (99.9%, 0.08mol), feed intake complete, be warming up to 130 ℃, stirring speed 600rpm, heat preservation reaction 6hr, pressure 2.2-2.5MPa, after the reaction, after cooling down and releasing the pressure to recover ammonia, 25.21g of copper ferrite was recovered by hot filtration at 60℃, and the filtrate was desolvated and negative pressure distillation to obtain 77.15g of Phenylenediamine, content 99.9%, yield 89.2%.

[0020] Apply mechanically recovery copper ferrite catalyst, repeat above-mentioned reaction process, catalyst apply mechanically 3 times, reaction situation is as follows.

[0021] Table 1 reclaims the reaction result 1 of nano-copper ferrite

[0022]

Embodiment 2

[0024] In 1L autoclave, add 58.86g p-dichlorobenzene (99.9%, 0.4mol), 302.3g water (45%, 8.0mol), 0.48g copper ferrite (99.9%, 0.002mol), after feeding, the temperature is raised to 150 ℃, stirring speed 600rpm, heat preservation reaction 10hr, pressure 4.2-4.8MPa, after the reaction, after cooling down and releasing the pressure to recover ammonia, 0.82g of copper ferrite was recovered by hot filtration at 80℃, and the filtrate was desolvated and negative pressure distilled to obtain 39.18g of Phenylenediamine, content 99.9%, yield 90.6%.

[0025] Apply mechanically recovery copper ferrite catalyst, repeat above-mentioned reaction process, catalyst apply mechanically 3 times, reaction situation is as follows.

[0026] Table 2 reclaims the reaction result 2 of nano-copper ferrite

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com