Preparation method of volume controllable PLGA microsphere

A PLGA and microsphere technology, applied in prosthesis, pharmaceutical formulations, medical science and other directions, can solve the problems such as the inability to flexibly control the size of PLGA microspheres, increase the complexity and cost of the preparation process, and the unchangeable particle size of PLGA microspheres, etc. To achieve the effect of reducing adverse reactions, protecting from damage, reducing drug toxicity and irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 supercritical fluid emulsion extraction method prepares PLGA microsphere

[0052] The common preparation methods of PLGA microspheres include the traditional emulsification solvent evaporation method and the emerging supercritical fluid injection method and supercritical fluid emulsion extraction method. This example uses the supercritical fluid emulsion extraction method as the preparation method to illustrate the PLGA microspheres. Ball preparation process.

[0053] Preparation of PLGA emulsion: 100 mg of PLGA (LA / GA=75 / 25, Mw50k) was weighed and dissolved in 10 ml of dichloromethane at room temperature as the oil phase. Dissolve PVA (Mw 20k-30k) in deionized water as the water phase. 10ml oil phase is dripped in 40ml water phase, under the action of the high-speed shear machine of 10000rpm, form the colostrum of coarse dispersion system under rotating speed; W-type PLGA emulsion.

[0054] Preparation of PLGA microsphere suspension: First, while heatin...

Embodiment 2

[0057] Example 2 Supercritical fluid water injection method to prepare volume-controllable PLGA microspheres

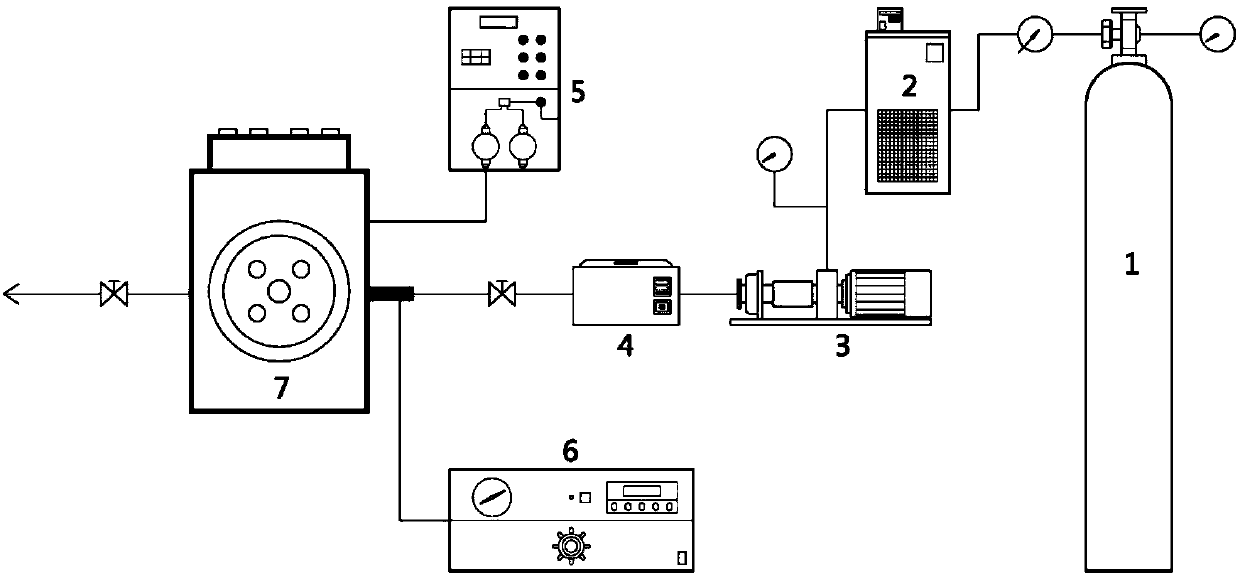

[0058] The PLGA microsphere suspension prepared in Example 1 is placed in the supercritical kettle 7, while the supercritical kettle 7 is heated and heated, the liquid carbon dioxide in the carbon dioxide steel cylinder 1 is condensed by the low temperature constant temperature tank of the condenser 2, and then passed through the high pressure After the pump 3 is compressed to the pressure-stabilizing tank, the pressure-stabilizing tank is preheated by the preheater 4, and then pumped into the supercritical kettle 7 through the outer channel of the coaxial two-flow nozzle to increase the pressure in the supercritical kettle 7. After the temperature and pressure in 7 rise to the preset supercritical temperature of 35°C and pressure of 10MPa, stabilize for a period of time, close the outlet valve and inlet valve of the supercritical kettle 7, and form airtight supercriti...

Embodiment 3

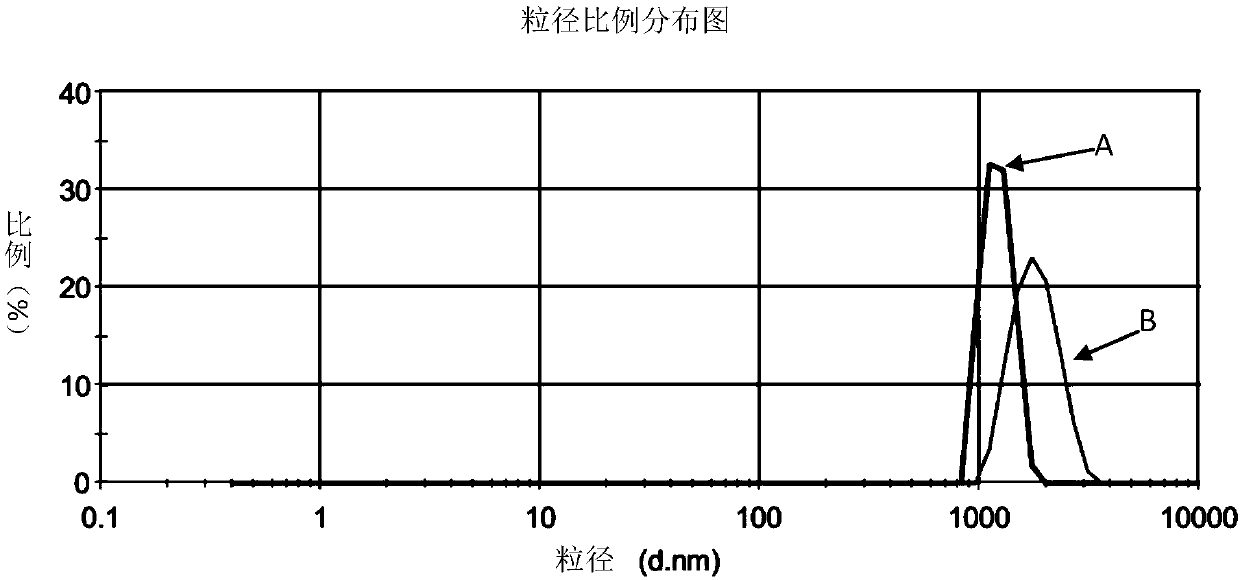

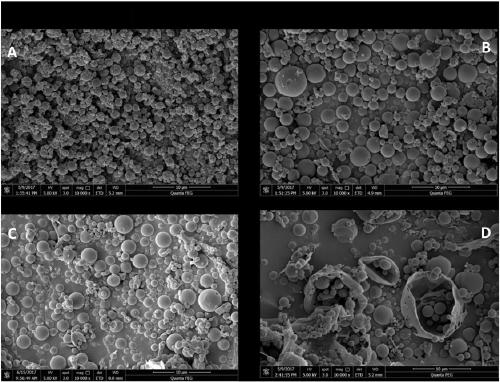

[0060] Example 3 Investigation of Pressure Factors of Supercritical Fluid Water Injection Method

[0061] The present embodiment supercritical fluid water injection method is the same as embodiment 2, keeps the supercritical temperature in the supercritical kettle 7 constant, and the swelling time is constant, and investigates with pressure (0MPa, 10MPa, 15MPa, 20MPa) as a single factor variable, According to the preparation method of Example 1, a PLGA microsphere suspension with a particle size of 0.1 to 1 μm was prepared, and it was used as a sample of this example, and the results were as follows image 3 shown. Electron micrograph of unswollen PLGA microsphere suspension under 0MPa pressure image 3 As shown in (A), the particle size of PLGA microspheres is 0.1-1 μm; the electron micrograph of PLGA microsphere suspension after swelling under 10MPa supercritical pressure condition is as follows image 3 As shown in (B), the particle size of PLGA microspheres is 1-4 μm; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap