A kind of preparation method of carbon-coated sodium vanadium phosphate composite cathode material

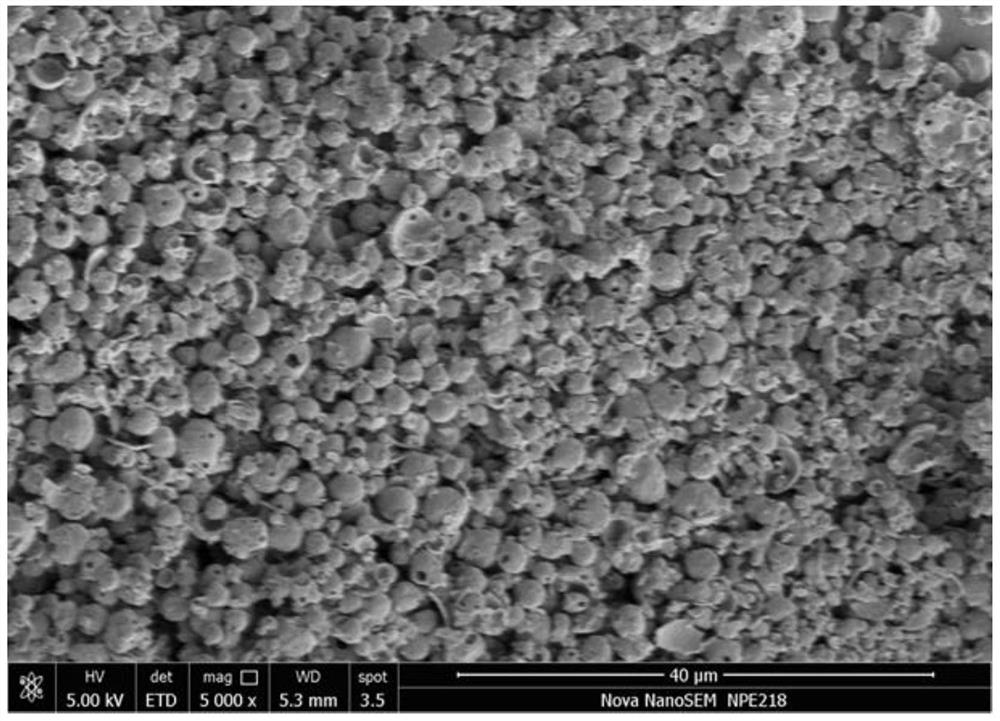

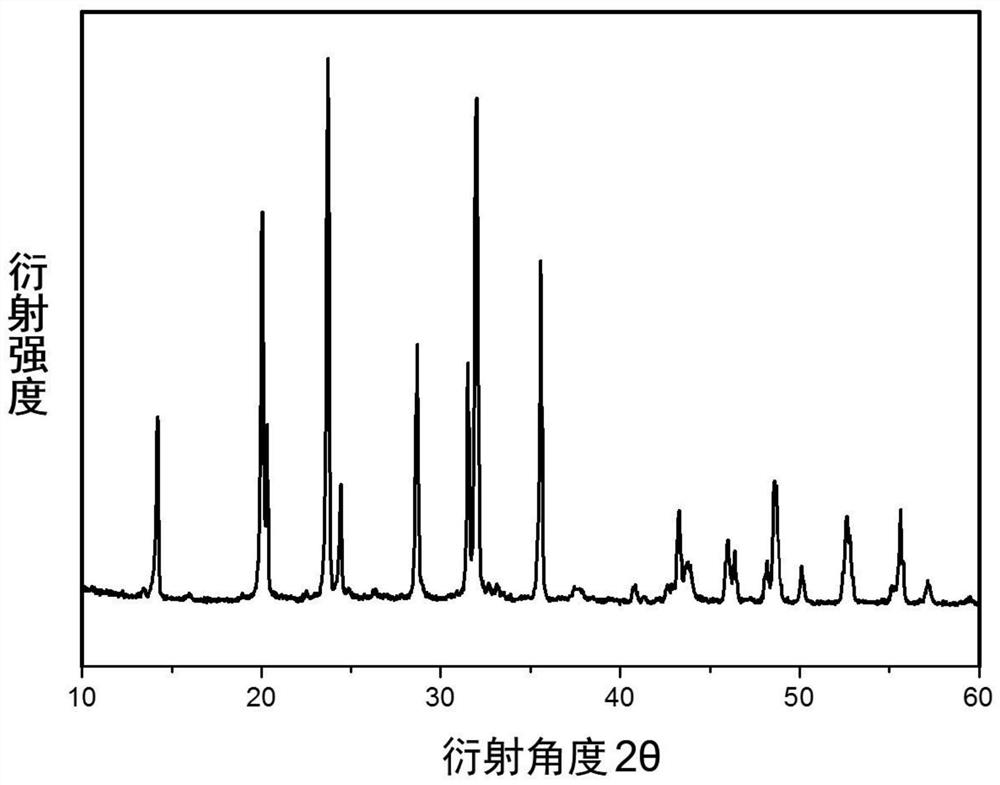

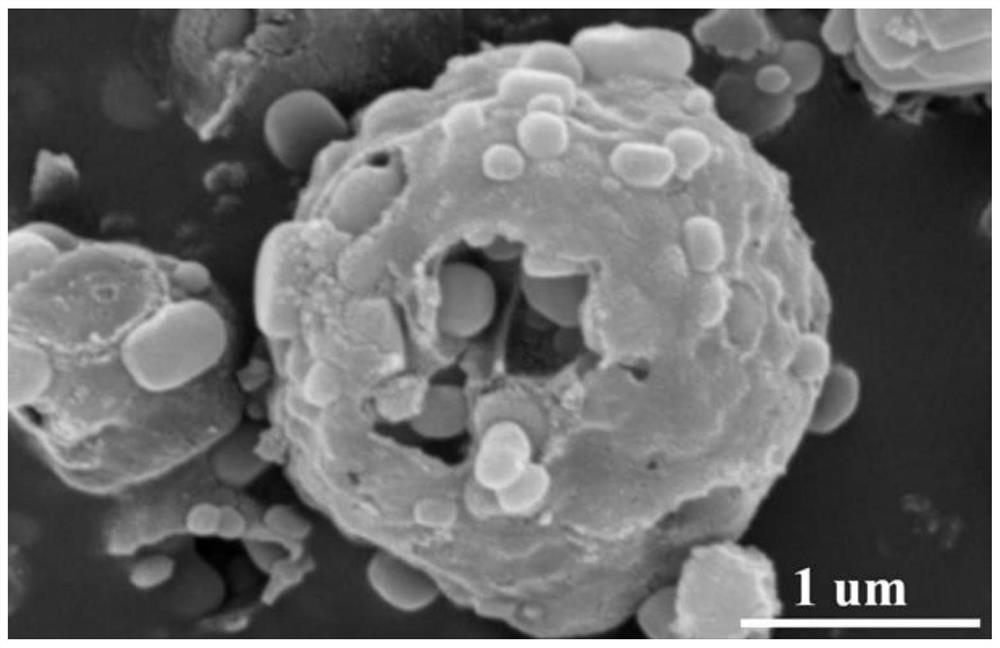

A technology of carbon-coated sodium vanadium phosphate and composite cathode materials, which is applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of difficulty in guaranteeing reproducibility, difficulty in large-scale production, and troublesome post-processing, and achieve consistency Good, uniform particle size, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for preparing a carbon-coated sodium vanadium phosphate composite cathode material, specifically comprising the following steps:

[0052] 1) Weigh 17.5467g of ammonium metavanadate, add 500mL of deionized water, heat to dissolve (the heating temperature is generally above 90°C), and obtain an aqueous solution containing vanadium source (wherein, the concentration of vanadium source is 0.2mol / L); then add 25.8818g ammonium dihydrogen phosphate, stirred and reacted in an oil bath at 90°C for 10 minutes to obtain reaction solution A; the pH value of reaction solution A was 4;

[0053] 2) Add 11.9239g of sodium carbonate to the reaction solution A for mixed reaction, the temperature of the mixed reaction is 88°C, and the mixed reaction time is 10min, until the solution no longer produces carbon dioxide bubbles, the reaction solution B is obtained; the pH of the reaction solution B is 7.5;

[0054] In the reaction solution B, the molar ratio of sodium atom, vanadiu...

Embodiment 2

[0059] A method for preparing a carbon-coated sodium vanadium phosphate composite cathode material, specifically comprising the following steps:

[0060] 1) Weigh 17.55g of ammonium metavanadate, add 500mL of deionized water, heat to dissolve (heating temperature is above 90°C), and obtain an aqueous solution containing vanadium source (wherein, the concentration of vanadium source is 0.2mol / L); then add 27.125 g of sodium dihydrogen phosphate, stirred and reacted in an oil bath at 95°C for 10 minutes to obtain reaction solution A; the pH value of reaction solution A was 5;

[0061] In reaction solution A, the molar ratio of sodium atom, vanadium atom and phosphorus atom is 3:2:3;

[0062] 2) Keeping this temperature, add 9.4g sucrose to the reaction solution A, the temperature of the mixing reaction is 90°C, and the time is 60min, until the solution turns dark green and the color does not change anymore. After the reaction is completed, the temperature is naturally lowered t...

Embodiment 3

[0066] 1) Weigh 17.5467g of ammonium metavanadate, add 500mL of deionized water, heat and dissolve at 95°C to obtain an aqueous solution with a concentration of 0.2mol / L; then add 25.8818g of ammonium dihydrogen phosphate, and stir for 10 minutes in an oil bath at 90°C. Obtain reaction solution A; The pH value of reaction solution A is 4;

[0067] 2) Add 11.9239g of sodium carbonate to the reaction solution A for mixed reaction, the temperature of the mixed reaction is 88°C, and the mixed reaction time is 10min, until the solution no longer produces carbon dioxide bubbles, the reaction solution B is obtained; the pH of the reaction solution B is 7.5;

[0068] In the reaction solution B, the molar ratio of sodium atom, vanadium atom and phosphorus atom is 3:2:3;

[0069] 3) Keeping this temperature, add 18.88g of glucose to the reaction solution B, the temperature of the mixed reaction is 90°C, and the time is 70min, until the solution turns dark green and the color does not c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com