Magnetic iron oxide and elemental selenium nano composite particles and preparation method and application thereof

A technology of magnetic iron oxide and composite particles, applied in the direction of elemental selenium/tellurium, pharmaceutical formulations, drug combinations, etc., can solve the problems of limited antibacterial effect, achieve enhanced penetration ability, good biocompatibility, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

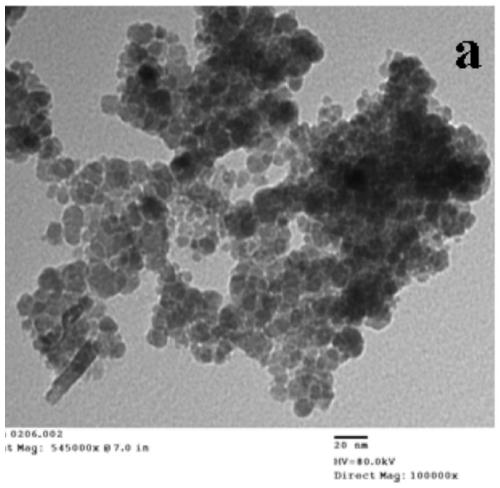

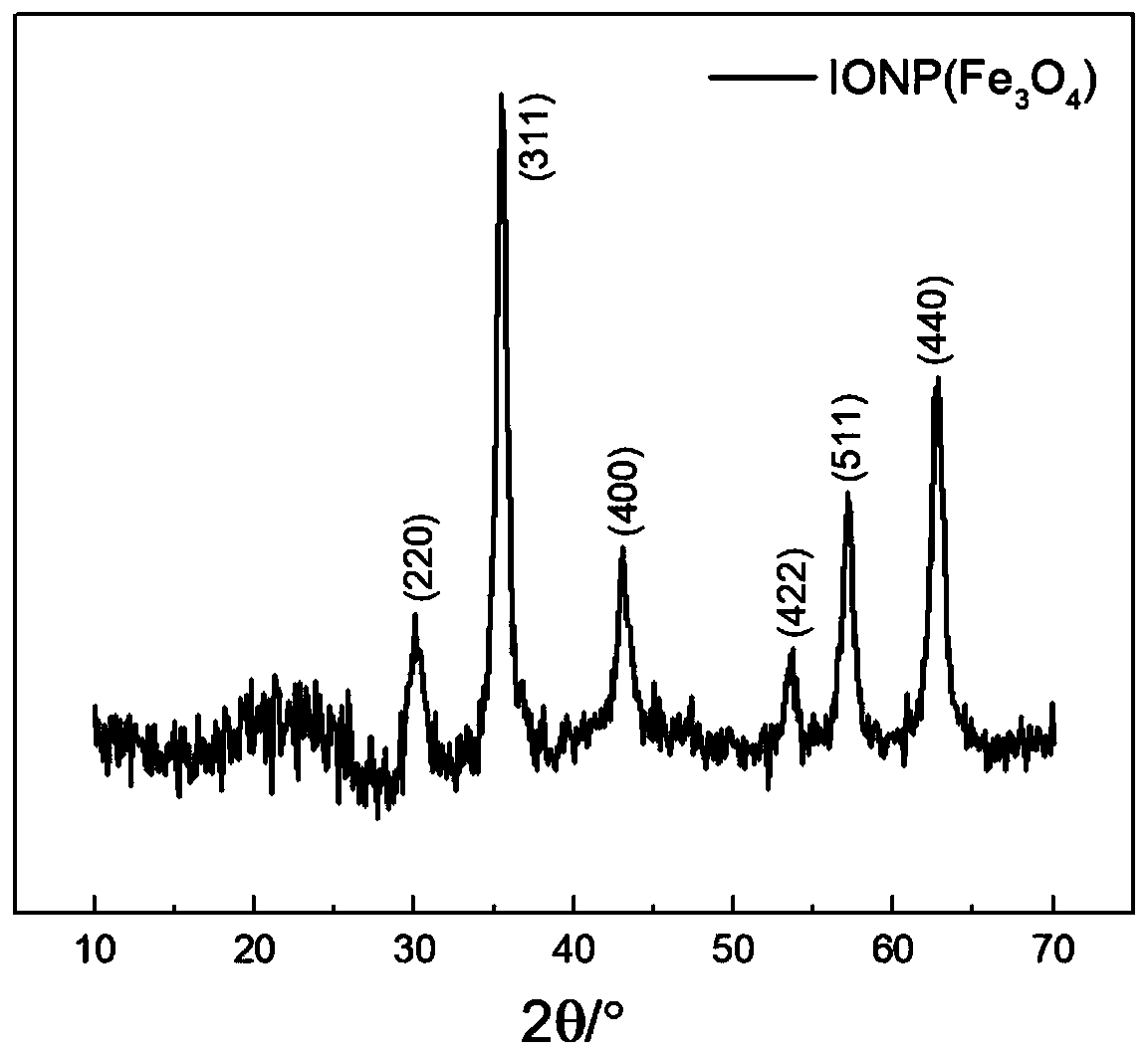

[0033] (1) Preparation of magnetic iron oxide nanoparticles: 0.15 g of low molecular weight chitosan (deacetylation degree of 75%-85%) was dissolved in 30 mL of 1% acetic acid solution, and the pH value was adjusted with 1.0 mol / L NaOH. to 4.8. Add 1.34gFeCl 2 4H 2 O and 3.40 g FeCl 3 ·6H 2 O in the above chitosan solution. The mixture was vigorously stirred, and 30 mL of 25% ammonia water and 10 mL of 0.75% TPP solution were added successively. The reaction was continued at 50° C. for 1 h, and the whole reaction was carried out under the condition of deoxygenation and nitrogen flow. After the reaction, the crude product was washed three times with deionized water, centrifuged and magnetically separated, and freeze-dried to obtain a solid magnetic iron oxide sample, which was confirmed by XRD to be magnetic ferric oxide with a particle size of 7.0-12.3nm.

[0034] (2) Preparation of magnetic iron oxide and elemental selenium nanocomposite particles; mix 8 mL of 0.07 mol / ...

Embodiment 2

[0038] (1) Preparation of magnetic iron oxide nanoparticles: same as in Example 1.

[0039] (2) Preparation of magnetic iron oxide and elemental selenium nanocomposite particles; mix 8 mL of 0.05 mol / L sodium selenite solution with 32 mL of 0.05 mol / L GSH solution, and shake at room temperature for 15 min on a platform shaker at a speed of 300rpm. Then, 100 mg of freeze-dried magnetic iron oxide nanoparticles were added, and the shaking was continued for 15 min. Add 3.5mL mol / L NaOH solution, the pH value of the solution is 11.73, and continue the reaction at 250rpm for 3h. The crude product was washed three times with deionized water, subjected to centrifugation and magnetic separation, and freeze-dried to obtain a solid composite microparticle sample.

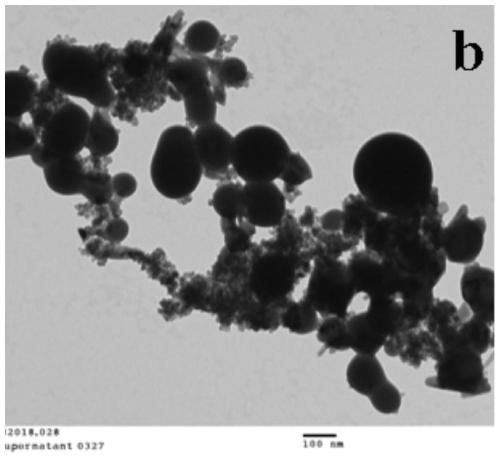

[0040] Figure 4 It is a transmission electron microscope picture of magnetic iron oxide and elemental selenium nanocomposite particles. The elemental selenium is in the shape of a rod, and the fine particles with lighter ...

Embodiment 3

[0042] (1) Preparation of magnetic iron oxide nanoparticles: same as in Example 1.

[0043] (2) Preparation of magnetic iron oxide and elemental selenium nanocomposite particles; mix 8mL 0.01mol / L sodium selenite solution with 32mL 0.01mol / L GSH solution, shake on a platform shaker for 15min at a speed of 300rpm . Then, 50 mg of freeze-dried magnetic iron oxide nanoparticles were added, and the shaking was continued for 15 min. Add 3.5mL mol / L NaOH solution, the pH value of the solution is 11.73, and continue the reaction at 250rpm for 3h. The crude product was washed three times with deionized water, subjected to centrifugation and magnetic separation, and freeze-dried to obtain a solid composite microparticle sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com