Bismuth ferrite-based ternary solid solution dielectric film material and preparation method thereof

A technology of dielectric film and solid solution, which is applied in the field of bismuth ferrite-based ternary solid solution dielectric film materials and its preparation, can solve the problems of low energy storage density, achieve high energy storage efficiency, excellent energy storage performance, large dielectric The effect of the electric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

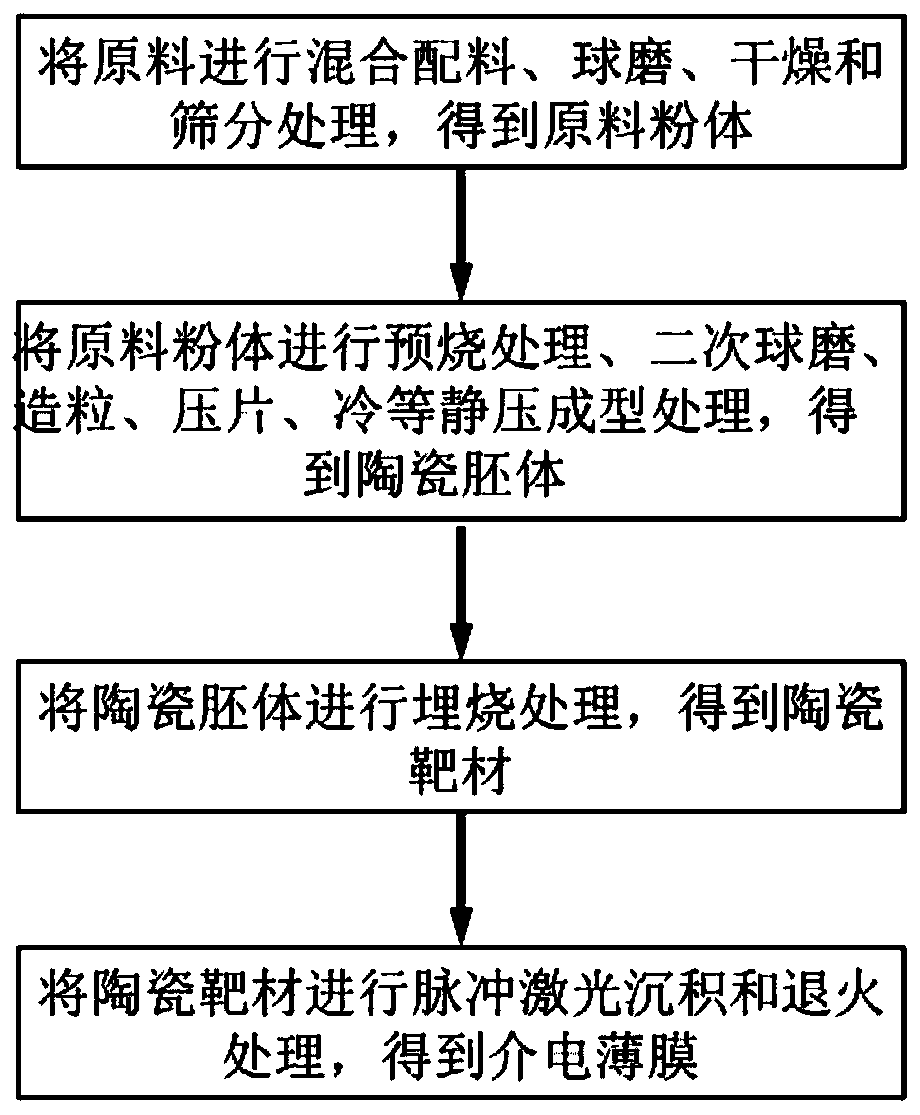

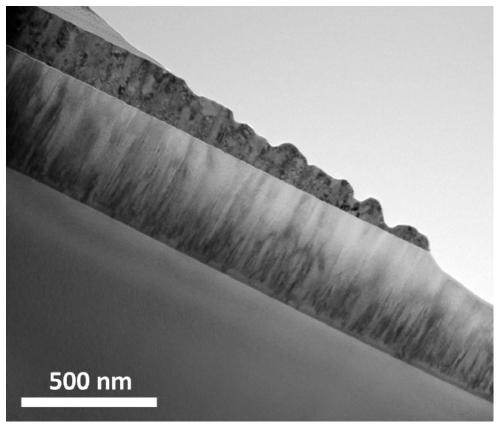

[0053] According to the method for preparing a bismuth ferrite-based ternary solid solution film for high-density dielectric energy storage according to an embodiment of the present invention, Bi 2 o 3 , Fe 2 o 3 、BaCO 3 , SrCO 3 and TiO 2 The raw materials are mixed according to the selected stoichiometric ratio, ball milled, dried and sieved to obtain the raw material powder of bismuth ferrite-based ternary solid solution dielectric film, Bi 2 o 3 The excess of raw materials can make up for the volatilization loss of Bi element in the subsequent preparation process. A uniform and dense bismuth ferrite-based ternary solid solution ceramic green body can be obtained by pre-calcining the raw material powder, secondary ball milling, granulation, tableting, and cold isostatic pressing. By burying and sintering the green body, a bismuth ferrite-based ternary solid solution ceramic target with high density, low porosity and low Bi volatilization can be obtained. By subjecti...

Embodiment 1

[0058] Raw material Bi 2 o 3 , Fe 2 o 3 、BaCO 3 , SrCO 3 and TiO 2 By (1-x-y)BiFeO 3 -xBaTiO 3 -ySrTiO 3 (x=0.3, y=0.45) carry out batching, wherein Bi 2 o 3 Raw material excess 10%. The raw material is ball milled with absolute ethanol for 8 hours, dried and sieved, and the obtained powder is pre-fired at 800 degrees Celsius for 2 hours. Dry the obtained powder after secondary ball milling for 8 hours, add polyvinyl alcohol solution with a concentration of 5% (mass percentage) to granulate, press it into a tablet under a 12MPa tablet press, and then use 25MPa cold isostatic pressure to maintain pressure for 10 minutes , Obtain a disc embryo body with a diameter of about 1 inch and a thickness of about 5 mm. After heat preservation and removal of polyvinyl alcohol, the green disc body was buried and fired at 1100 degrees Celsius for 2 hours to obtain a high-quality bismuth ferrite-based ternary solid solution ceramic target.

[0059] The pulsed laser bombards the ...

Embodiment 2

[0062] Raw material Bi 2 o 3 , Fe 2 o 3 、BaCO 3 , SrCO 3 and TiO 2 By (1-x-y)BiFeO 3 -xBaTiO 3 -ySrTiO 3 (x=0.2, y=0.45) carry out batching, wherein Bi 2 o 3 Raw material excess 15%. The raw material is ball milled with absolute ethanol for 8 hours, dried and sieved, and the obtained powder is pre-fired at 780 degrees Celsius for 2 hours. Dry the obtained powder after secondary ball milling for 8 hours, add polyvinyl alcohol solution with a concentration of 5% (mass percentage) to granulate, press it into a tablet under a 12MPa tablet press, and then use 25MPa cold isostatic pressure to maintain pressure for 10 minutes , Obtain a disc embryo body with a diameter of about 1 inch and a thickness of about 5 mm. After heat preservation and removal of polyvinyl alcohol, the green disc body was buried and fired at 1080 degrees Celsius for 1.5 hours to obtain a high-quality bismuth ferrite-based ternary solid solution ceramic target.

[0063] The pulsed laser bombards th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com