Water-based microcapsule sand washing composition for highly acidic gas wells, water-based microcapsule sand washing fluid for high acid gas wells

An acid gas, well water-based technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of reducing the risk of hydrogen sulfide escape, affecting the stability of sand washing foam liquid, increasing liquid consumption and construction costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

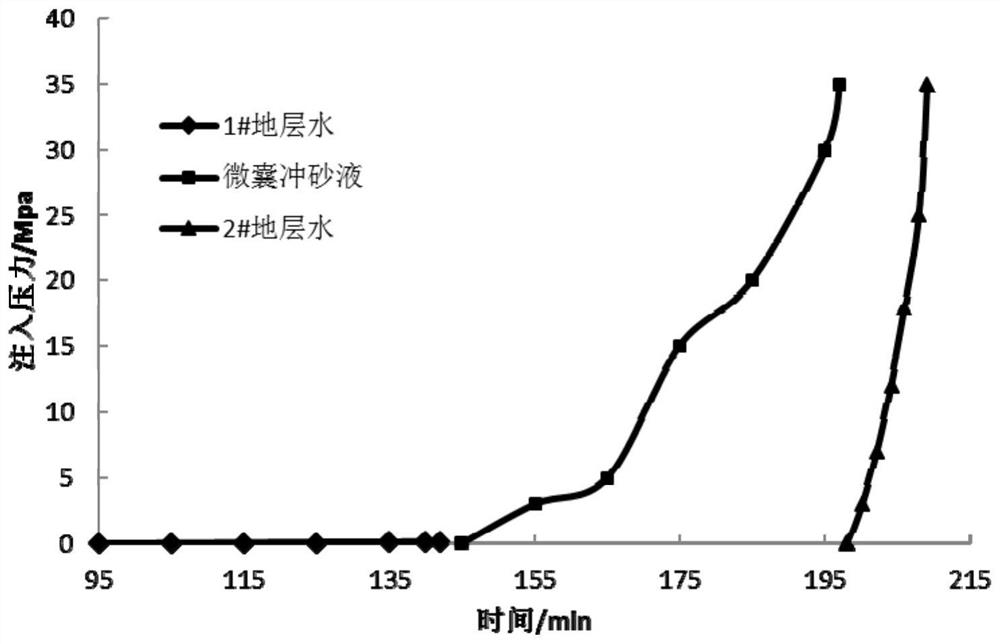

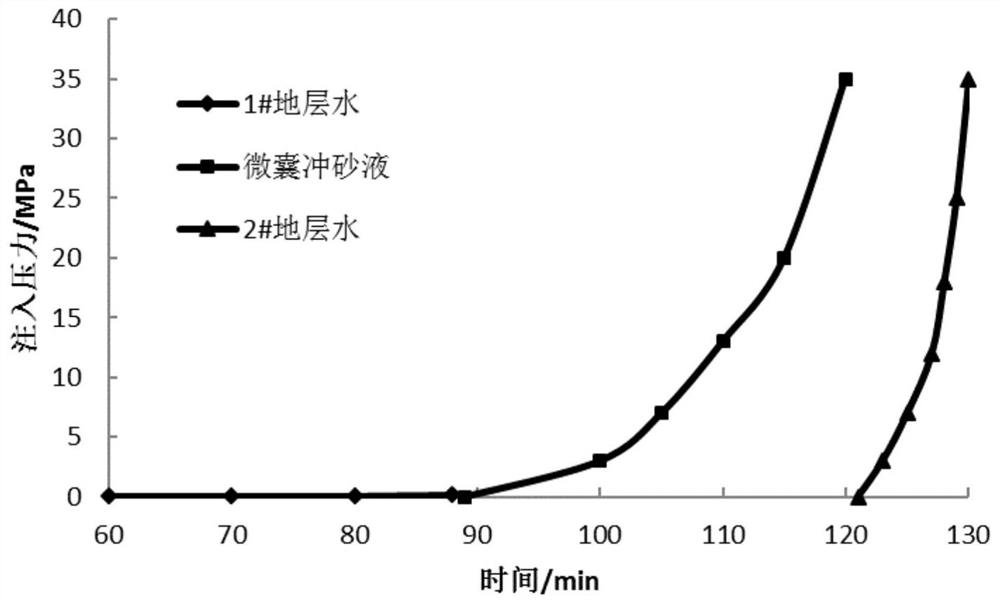

Examples

preparation example Construction

[0053] Table 1 Preparation of modified carboxymethyl cellulose

[0054]

[0055] Note: % in Table 1 means mass fraction.

Embodiment 1

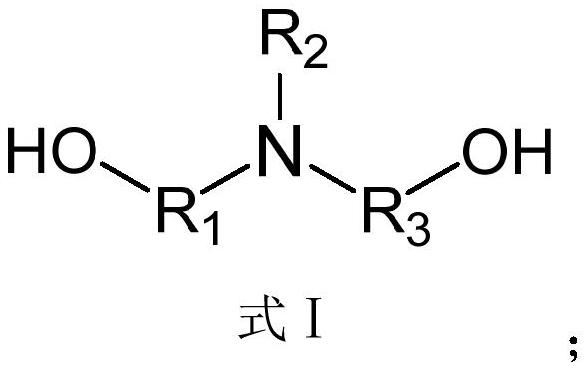

[0057] The capsule reinforcing agent adopted in this embodiment is water-soluble phenolic resin modified carboxymethyl cellulose; the foam stabilizer is isopropanolamine and N-methyldiethanolamine, isopropanolamine and N-methyldiethanolamine The mass ratio is 2:1; the foaming agent is composed of anionic surfactant and cationic surfactant, the mass ratio of anionic surfactant and cationic surfactant is 3:1, and the anionic surfactant is dodecylsulfuric acid Sodium, the cationic surfactant is ethyl-α, ω-ditetradecyldimethylammonium bromide; the sulfur removal agent is 1,3,5-tris(2-hydroxyethyl)-hexahydro-same oxazine; the corrosion inhibitor is l-hydroxyethyl-2-oleic acid imidazoline quaternary ammonium salt; the pH regulator is sodium carbonate.

[0058] The high-acid gas well water-based microcapsule sand washing composition of this embodiment is composed of the following components in parts by weight: 0.6 parts of foaming agent, 1.5 parts of capsule membrane enhancer, 1.2 pa...

Embodiment 2

[0064] The capsule reinforcing agent adopted in this embodiment is sodium silicate modified carboxymethyl cellulose; the foam stabilizer is diethanolamine and N-methyldiethanolamine, and the mass ratio of diethanolamine and N-methyldiethanolamine is 1 :1; Foaming agent is made up of anionic surfactant and cationic surfactant, and the mass ratio of anionic surfactant and cationic surfactant is 3:2, and anionic surfactant is sodium dodecylbenzene sulfonate, cationic surfactant The surfactant is tetradecyltrimethylammonium bromide; the sulfur removal agent is tri-p-hydroxyphenylazine, and the corrosion inhibitor is 1-(2-amino-thioureamethyl)-2-pentadecylimidazole Phylline quaternary ammonium salt; pH regulator is sodium hydroxide.

[0065] The water-based microcapsule sand washing composition for high-acid gas wells of this embodiment is composed of the following components in parts by weight: 1.3 parts of foaming agent, 2.8 parts of capsule membrane enhancer, 2.2 parts of foam s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com